Method for rapidly preparing carbon-coated nano TinO2n-1@C nano powder

A technology of titanium oxide and nano-powder, which is applied in the field of rapid preparation of carbon-coated nano-titanium oxide nano-powder, can solve the problems of inability to prepare titanium oxide powder and large particle size of titanium oxide powder, and achieve Short preparation cycle and the effect of inhibiting sintering and agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

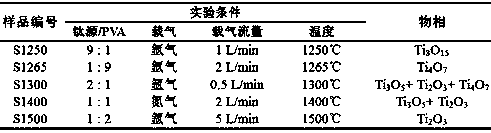

[0024] Mix commercial P25 powder and polyvinyl alcohol powder at a mass ratio of 2:1, and dry the mixed material (P25+PVA) in a drying oven at 80°C overnight for use.

[0025] Vacuumize the rapid heat treatment furnace and fill it with argon as a protective gas. After raising the furnace temperature to the target temperature of 1300°C, use argon as the carrier gas and send the mixed material into the rapid heat treatment process at a flow rate of 0.5 L / min. The high-temperature heating zone of the furnace; the material reacts rapidly under the drive of argon and falls into the powder cooling collection device, that is, carbon-coated titanium dioxide nanopowder (Ti n o 2n-1 @C).

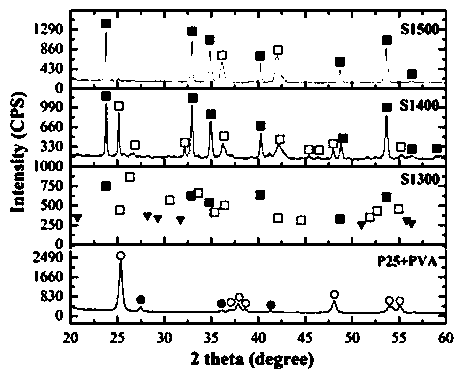

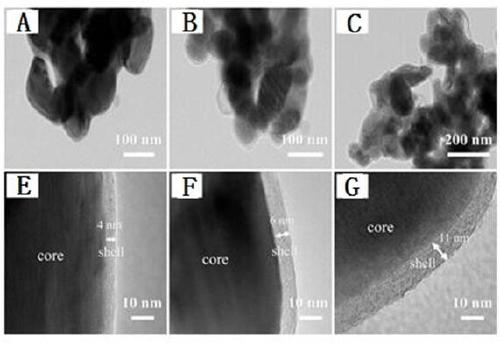

[0026] The product phase obtained in this embodiment is Ti 4 o 7 , Ti 3 o 5 , Ti 2 o 3 And with Ti 4 o 7 Based on TEM photo analysis, the particle size is about 100nm, and the thickness of the carbon shell is 4nm. The product phase results are as follows figure 1 shown in S1300, and summari...

Embodiment 2

[0028] Mix rutile metatitanic acid powder and polyvinyl alcohol powder at a mass ratio of 1:1, and dry the mixed material (rutile metatitanic acid + PVA) in a drying oven at 80°C overnight for use.

[0029] Vacuumize the rapid heat treatment furnace and fill it with nitrogen as a protective gas. After raising the furnace temperature to the target temperature of 1400°C, use nitrogen as the carrier gas and send the mixed material into the rapid heat treatment furnace at an air flow rate of 2L / min. The high-temperature heating zone; the material reacts rapidly under the drive of argon and falls into the powder cooling collection device, that is, carbon-coated titanium dioxide nanopowder (Ti n o 2n-1 @C).

[0030] The product phase obtained in this embodiment is Ti 3 o 5 , Ti 2 o 3 , the particle size is about 100 nm and the carbon shell thickness is 6 nm through TEM photo analysis; the product phase results are as follows figure 1 S1400 is shown and summarized in Table 1, ...

Embodiment 3

[0032] Mix rutile metatitanic acid powder and polyvinyl alcohol powder at a mass ratio of 1:2, and dry the mixed material (rutile metatitanic acid + PVA) in a drying oven at 80°C overnight for use.

[0033] Vacuumize the rapid heat treatment furnace and fill it with argon as a protective gas. After raising the furnace temperature to the target temperature of 1500°C, use argon as the carrier gas and send the mixed material into the rapid heat treatment furnace at a flow rate of 5L / min. The high-temperature heating zone; the material reacts rapidly under the drive of argon and falls into the powder cooling collection device, that is, carbon-coated titanium dioxide nanopowder (Ti n o 2n-1 @C).

[0034] The product obtained in this embodiment is analyzed by XRD, and the phase is Ti 2 o 3 , the particle size is about 110nm and the carbon shell thickness is 11nm through TEM photo analysis; the product phase results are as follows figure 1 S1500 is shown and summarized in Table ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com