Hybridized film modified carbon fiber composite material and preparation method thereof

A composite material and composite material layer technology, applied in the field of high-performance carbon fiber composite materials, can solve problems such as poor toughness and electrical conductivity, and achieve the effects of increasing interlaminar fracture toughness, reducing costs, and making costs reasonable.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

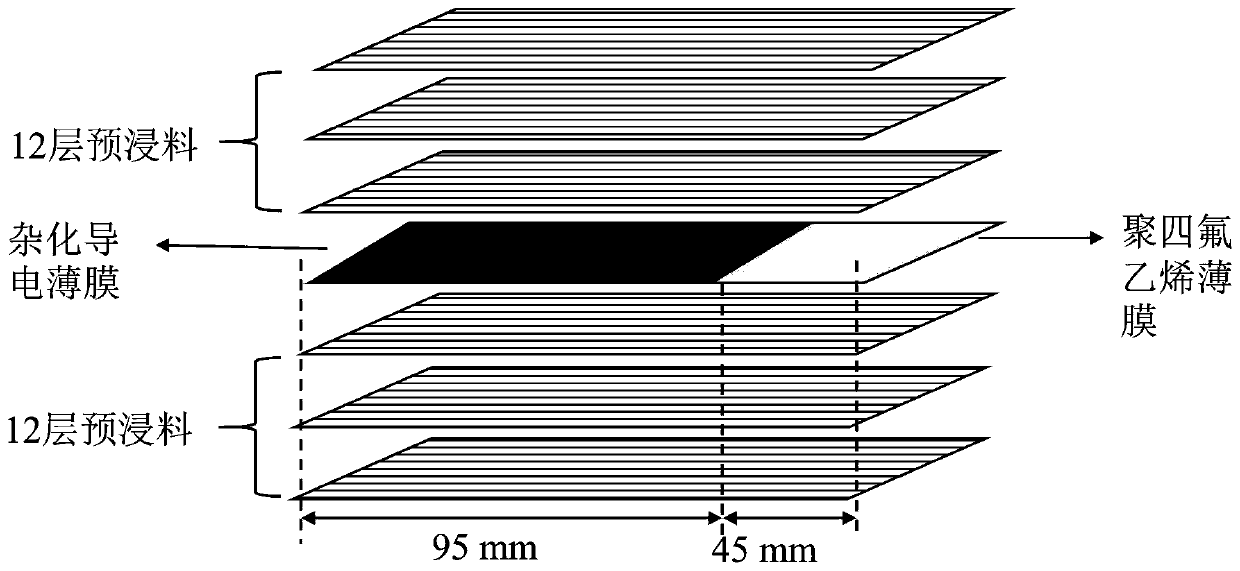

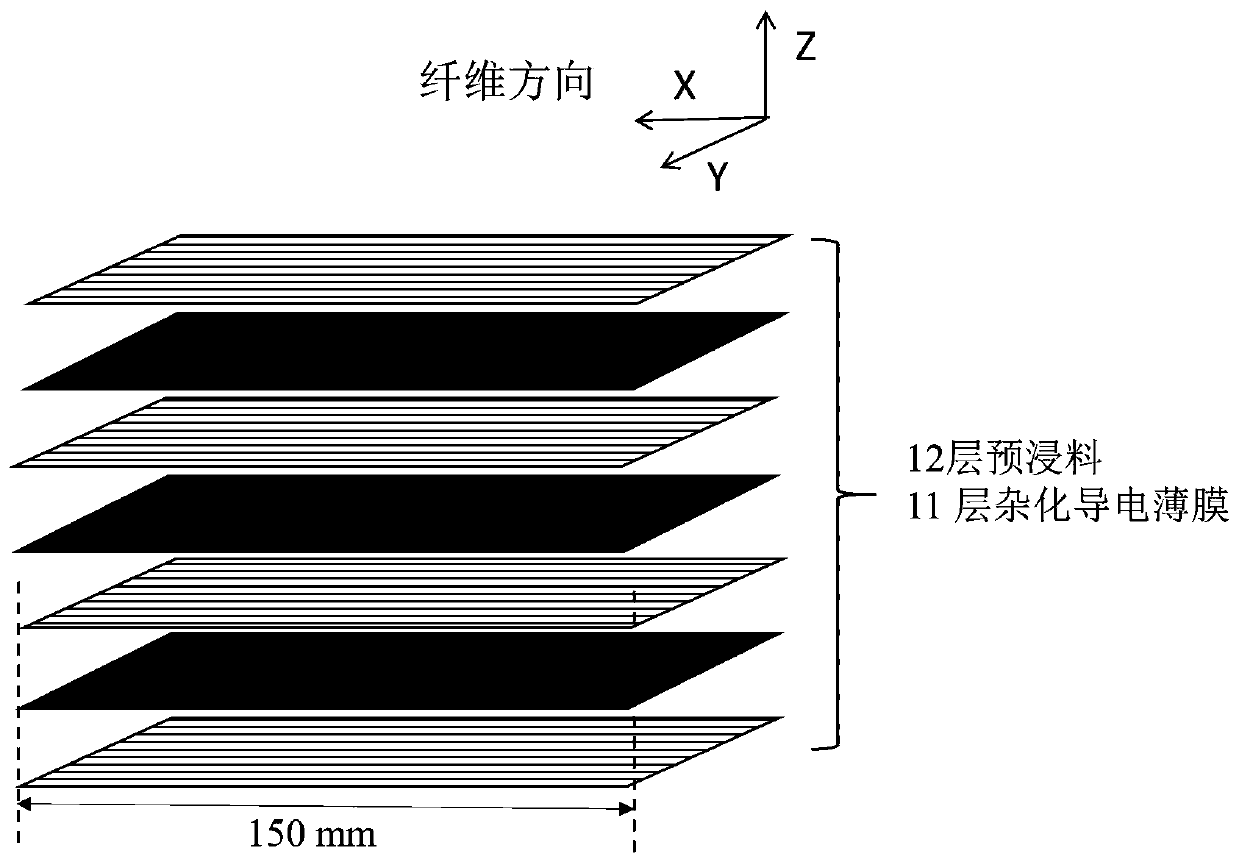

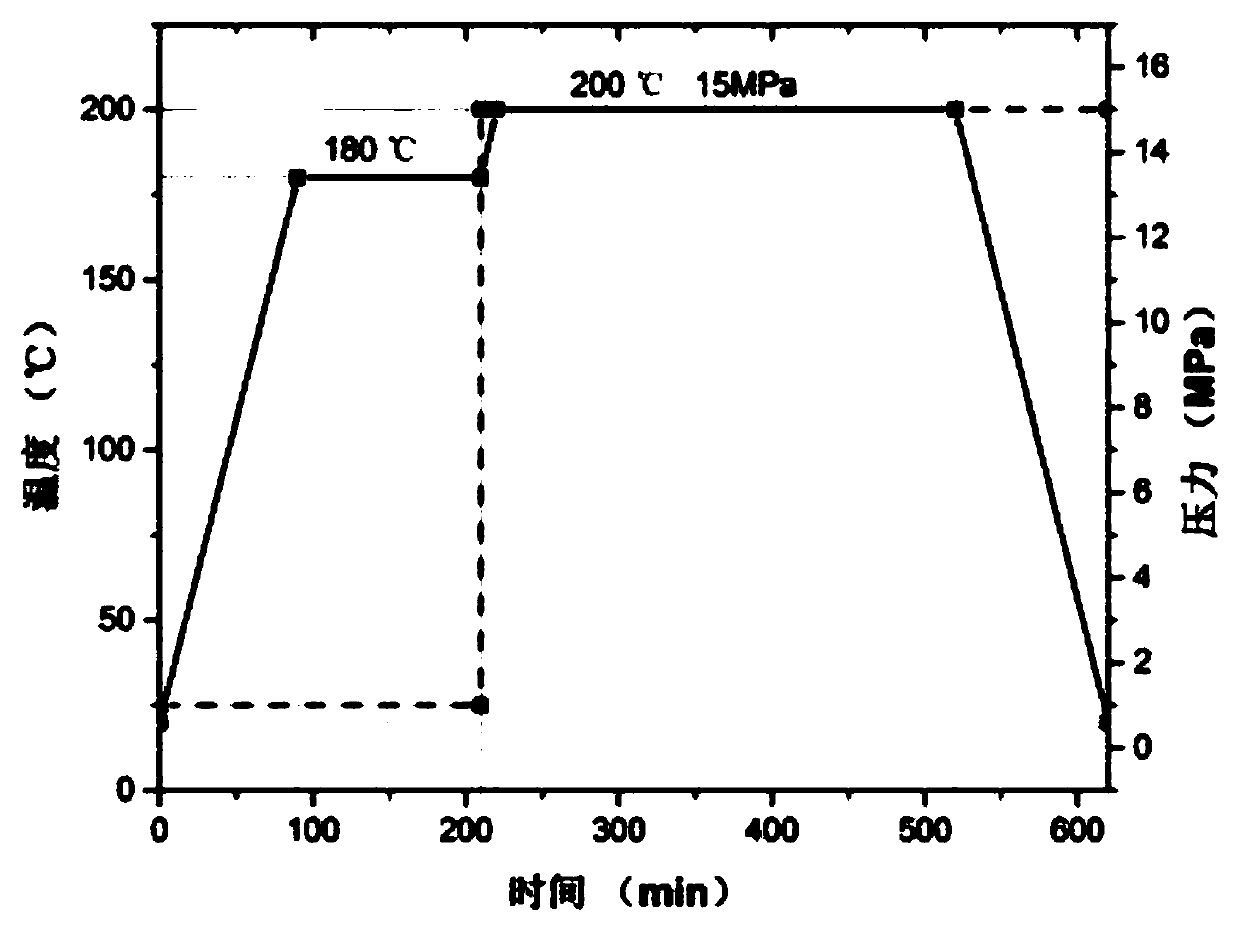

[0024] A preparation method of a hybrid film modified carbon fiber composite material, the steps are as follows:

[0025] S1. Preparation of CNT / AgNP composite filler: the composite weight ratio of CNT and AgNP is 10:1, the amount of silver nitrate is 0.12mM (millimoles), the amount of carbon nanotubes is 1mg, the amount of sodium citrate solution is 10mL, sodium citrate The mass fraction of the aqueous solution is 1 wt%. The average diameter of the carbon nanotubes used is 9.5nm, the average length is 1.5μm, and the specific surface area is 250~300m 2 / g. Specific operation: Put the silver nitrate aqueous solution, carbon nanotubes and sodium citrate aqueous solution in a flask in turn, place the flask in an oil bath and heat it in an oil bath. Stir and react at 120°C for 1 hour until the solution turns gray. Centrifuge (centrifuge) Speed 10000rpm), the precipitate obtained is the CNT / AgNP composite filler; the composite filler is stored in absolute ethanol for later use;

[0...

Embodiment 2

[0032] A preparation method of hybrid film modified carbon fiber composite material, the steps are as follows:

[0033] S1. Preparation of CNT / AgNP composite filler: the composite weight ratio of CNT and AgNP is 5:1, the amount of silver nitrate is 0.22mM (millimoles), the amount of carbon nanotubes is 1mg, the amount of sodium citrate solution is 10mL, sodium citrate The mass fraction of the aqueous solution is 1 wt%. The average diameter of the carbon nanotubes used is 9.5nm, the average length is 1.5μm, and the specific surface area is 250~300m 2 / g. Specific operation: Put the silver nitrate aqueous solution, carbon nanotubes and sodium citrate aqueous solution in a flask in turn, place the flask in an oil bath and heat it in an oil bath, stir and react at 110°C for 2 hours, until the solution turns gray, and centrifuge (centrifuge) Rotation speed 10000rpm), the precipitate obtained is the CNT / AgNP composite filler; the composite filler is stored in absolute ethanol for late...

Embodiment 3

[0038] A preparation method of hybrid film modified carbon fiber composite material, the steps are as follows:

[0039] S1. Preparation of CNT / AgNP composite filler: the composite weight ratio of CNT and AgNP is 2:1, the amount of silver nitrate is 0.53mM (millimoles), the amount of carbon nanotubes is 1mg, the amount of sodium citrate aqueous solution is 10mL, sodium citrate The mass fraction of the aqueous solution is 1 wt%. The average diameter of the carbon nanotubes used is 9.5nm, the average length is 1.5μm, and the specific surface area is 250~300m 2 / g. Specific operation: Put the silver nitrate aqueous solution, carbon nanotubes and sodium citrate aqueous solution in a flask in turn, place the flask in an oil bath and heat it in an oil bath, stir and react at 110°C for 2 hours, until the solution turns gray, and centrifuge (centrifuge) Rotation speed 10000rpm), the precipitate obtained is the CNT / AgNP composite filler; the composite filler is stored in absolute ethanol ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com