SPS connecting method of WRe/TZM/graphite

A connection method and graphite technology, applied in the field of SPS sintering connection of WRe/TZM/graphite, can solve the problems of serious material loss, alloy surface carbonization, complicated process, etc., and achieve the reduction of production cycle and cost, dense sintering, and simple process flow Effect

- Summary

- Abstract

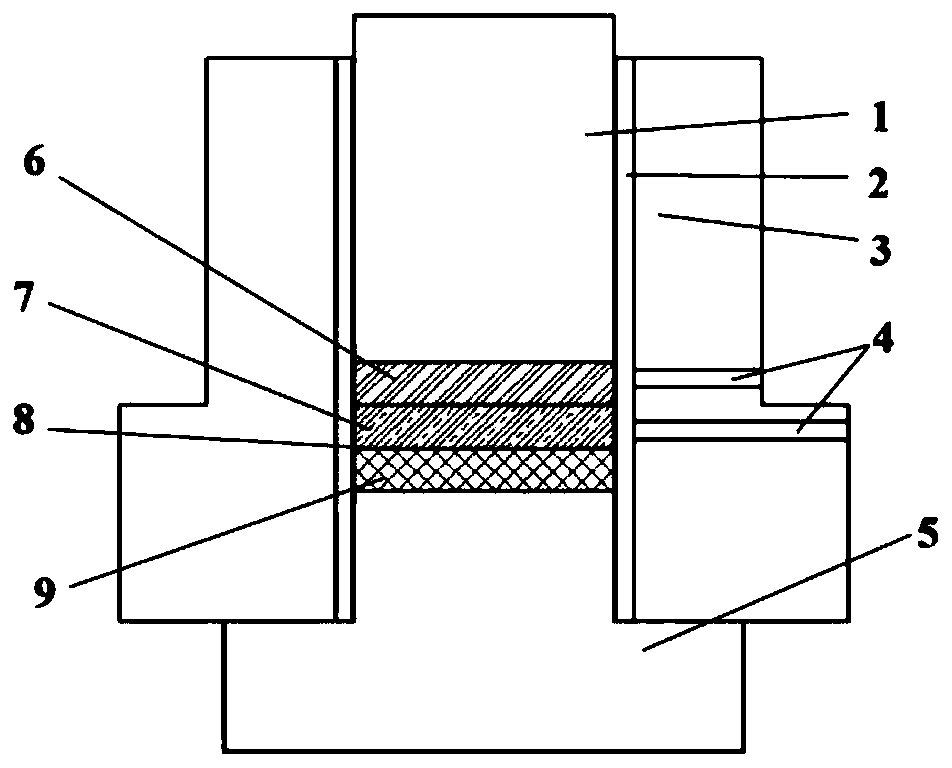

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] In the present embodiment, the SPS diffusion welding of TZM and graphite dissimilar materials is carried out as follows:

[0041] 1. Take the graphite to be connected, pre-grind, polish, ultrasonically clean and vacuum-dry the graphite surface to be welded to ensure that the flatness of the graphite surface to be welded is not greater than 0.1mm and the roughness is not greater than 0.1μm.

[0042]2. Pickle the titanium foil in dilute hydrochloric acid with a volume concentration of 5% for 10 minutes, then place it in alcohol for ultrasonic cleaning, and finally dry it for later use.

[0043] 3. Weigh W-5% Re alloy powder and TZM alloy powder raw materials as required.

[0044] 4. Take the graphite die and install the bushing and the lower pressure head, put the weighed TZM alloy powder and WRe alloy powder into the graphite mold in turn, and use a manual hydraulic press to pre-press respectively, the pressure is 10MPa, and the pressure is maintained for 2min , and the...

Embodiment 2

[0052] In the present embodiment, the SPS diffusion welding of TZM and graphite dissimilar materials is carried out as follows:

[0053] 1. Take the graphite to be connected, pre-grind, polish, ultrasonically clean and vacuum-dry the graphite surface to be welded to ensure that the flatness of the graphite surface to be welded is not greater than 0.1mm and the roughness is not greater than 0.1μm.

[0054] 2. Pickle the titanium foil in dilute hydrochloric acid with a volume concentration of 5% for 10 minutes, then place it in alcohol for ultrasonic cleaning, and finally dry it for later use.

[0055] 3. Weigh W-5% Re alloy powder and TZM alloy powder raw materials as required.

[0056] 4. Take the graphite die and install the bushing and the lower pressure head, put the weighed TZM alloy powder and WRe alloy powder into the graphite mold in turn, and use a manual hydraulic press to pre-press respectively, the pressure is 10MPa, and the pressure is maintained for 2min , and th...

Embodiment 3

[0064] In the present embodiment, the SPS diffusion welding of TZM and graphite dissimilar materials is carried out as follows:

[0065] 1. Take the graphite to be connected, pre-grind, polish, ultrasonically clean and vacuum-dry the graphite surface to be welded to ensure that the flatness of the graphite surface to be welded is not greater than 0.1mm and the roughness is not greater than 0.1μm.

[0066] 2. Pickle the titanium foil in dilute hydrochloric acid with a volume concentration of 5% for 10 minutes, then place it in alcohol for ultrasonic cleaning, and finally dry it for later use.

[0067] 3. Weigh W-5% Re alloy powder and TZM alloy powder raw materials as required.

[0068] 4. Take the graphite die and install the bushing and the lower pressure head, put the weighed TZM alloy powder and WRe alloy powder into the graphite mold in turn, and use a manual hydraulic press to pre-press respectively, the pressure is 10MPa, and the pressure is maintained for 2min , and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com