Pure metal fiber fabric filter composite material and preparation method thereof

A fiber fabric and composite material technology, which is applied in the field of environmental treatment materials preparation, can solve the problems affecting the service life of sintered felt and weak mechanical properties, and achieve the effects of small friction, long replacement cycle and improved filtration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

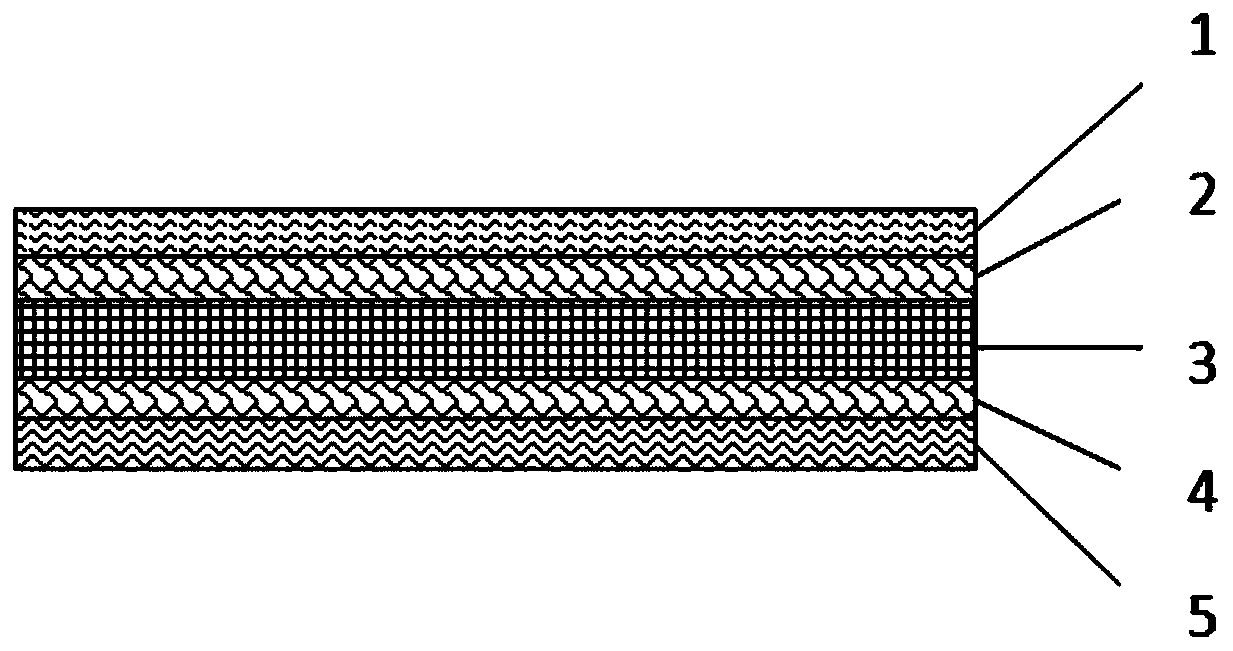

[0026] see figure 1 , the present invention provides a high-temperature-resistant pure metal fiber fabric filter composite material, which sequentially includes a dust-facing layer 1 treated with an anti-corrosion coating, a first adhesion layer 2 composed of pure metal fiber knitted fabric, and a base cloth layer 3 from outside to inside , the second adhesion layer 4 and the bottom layer 5 made of pure metal fiber knitted fabric.

[0027] The base fabric layer 3 is a woven fabric, which is formed by interweaving pure stainless steel fiber yarns through plain weave or twill weave. The diameter of the stainless steel fibers is 40-60 μm, preferably 50 μm. The linear density of the stainless steel fiber yarns is 400-600tex, preferably 500tex; stainless steel fiber yarn is formed by plying 3 single-strand metal yarns;

[0028] The dust-facing layer 1 is a fiber felt, which is formed by fine stainless steel fibers through drawing, opening, carding, laying, calendering, and sinteri...

Embodiment 2

[0037] see figure 1 , the present invention provides a high-temperature-resistant pure metal fiber fabric filter composite material, which sequentially includes a dust-facing layer 1 treated with an anti-corrosion coating, a first adhesion layer 2 composed of pure metal fiber knitted fabric, and a base cloth layer 3 from outside to inside , the second adhesion layer 4 and the bottom layer 5 made of pure metal fiber knitted fabric.

[0038] The base fabric layer 3 is a woven fabric, the woven fabric is made of iron-chromium-aluminum fiber yarn through plain weave or twill weave, the diameter of the stainless steel fiber is 10-30 μm, preferably 24 μm, and the diameter of the iron-chromium-aluminum fiber yarn is 10-30 μm. The linear density is 200-400tex, preferably 300tex; the stainless steel fiber yarn is formed by plying three single-strand metal yarns;

[0039] The dust-facing layer 1 is a fiber felt, which is formed by fine stainless steel fibers through drawing, opening, c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com