A Remanufacturing and Strengthening Method of Structural Pores Based on Friction Stir Bonding

A technology of friction stir and structural holes, which is applied in the field of remanufacturing and strengthening of holes in light metal structural parts, remanufacturing and strengthening of structural holes. Effects of small deformation, easy implementation, and simple processing procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below with reference to the drawings and examples, but the embodiments of the present invention are not limited thereto.

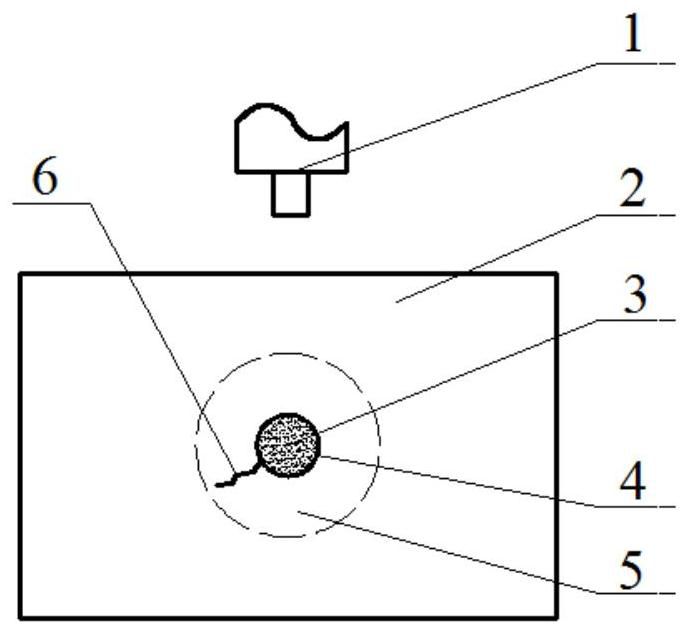

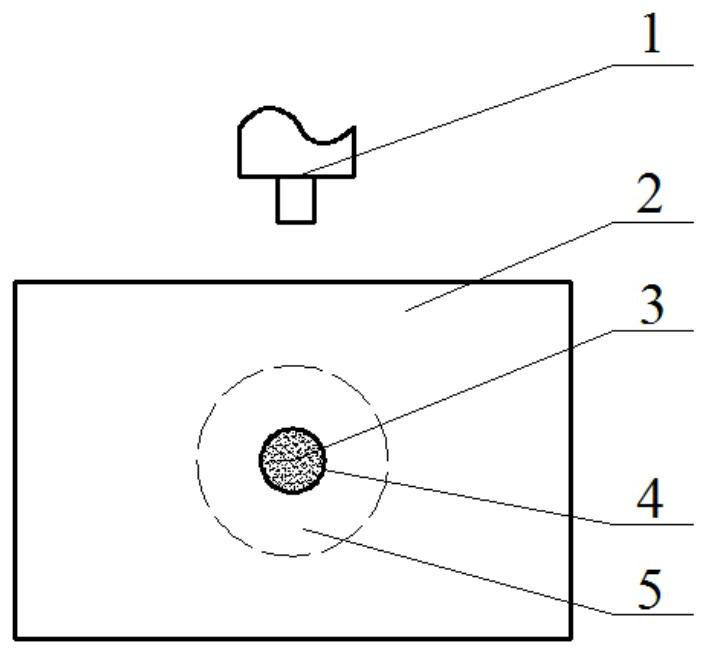

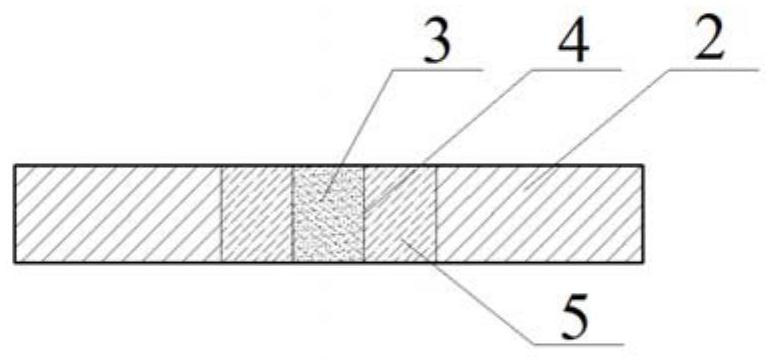

[0027] Such as Figure 1-3 as shown,

[0028] A structural hole remanufacturing and strengthening method based on friction stir bonding, which comprises the following steps:

[0029] 1) According to the type of metal material of the structural parts, the metal material is used as the matrix, and the hard nano-particles are used as the reinforcement of the reinforcement phase by powder metallurgy. 3, the powder metallurgy production can effectively increase the compactness between the nanoparticles. The amount of added is added according to the service state of the structural part and the performance of the matrix metal of the structural part (generally, the volume fraction of hard nanoparticles in reinforcement 3 is 1-40%). The diameter of the reinforcing body 3 is the same as that of the structural ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com