Surface modified organic-inorganic hybrid perovskite material and modification method and application thereof

A perovskite material and surface modification technology, applied in photovoltaic power generation, electrical components, electrical solid devices, etc., can solve problems such as low energy and power density, incompatible manufacturing processes, and long time-consuming surface modification. Effects of defects, short wavelength, and short time consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Preparation of dense TiO on FTO conductive glass substrate by sol-gel method 2 Thin film: spin-coat titanium isopropoxide ethanol solution with a concentration of 0.2mol / L on a clean FTO conductive glass substrate, and anneal at 500°C for 30 minutes to obtain dense TiO 2 The thin film acts as a hole-blocking layer and an electron-transporting layer.

[0028] (2)CH 3 NH 3 PB 3 Preparation of thin film: appropriate amount of PbI 2 and CH 3 NH 3I is dissolved in the mixed solvent (DMF and DMSO volume ratio is 8:2) of N,N-dimethylformamide (DMF) and dimethyl sulfoxide (DMSO) according to the molar ratio of 1:1, obtains concentration: 1.2mol / L of CH 3 NH 3 PB 3 Precursor solution; in a nitrogen glove box, CH 3 NH 3 PB 3 Precursor solution spin-coated on dense TiO 2 On top of the film, and 1 mL of chlorobenzene was added dropwise during the spin-coating process, and then the obtained film was heat-treated at 70 °C for 10 minutes and 100 °C for 10 minutes to o...

Embodiment 2

[0033] (1) Prepare dense TiO with a thickness of about 40 nm on an 80 mm × 80 mm FTO conductive glass substrate by magnetron sputtering 2 The thin film acts as a hole-blocking layer and an electron-transporting layer.

[0034] (2) Vacuum thermal evaporation method is used to make dense TiO 2 Evaporate about 220nm thick PbI on the electron transport layer 2 film, which was then soaked in 10 mg / mL CH 3 NH 3 I in the isopropanol solution of I for 30 minutes, take it out and heat it on a hot stage at 100°C for 20 minutes to obtain CH 3 NH 3 PB 3 perovskite thin film.

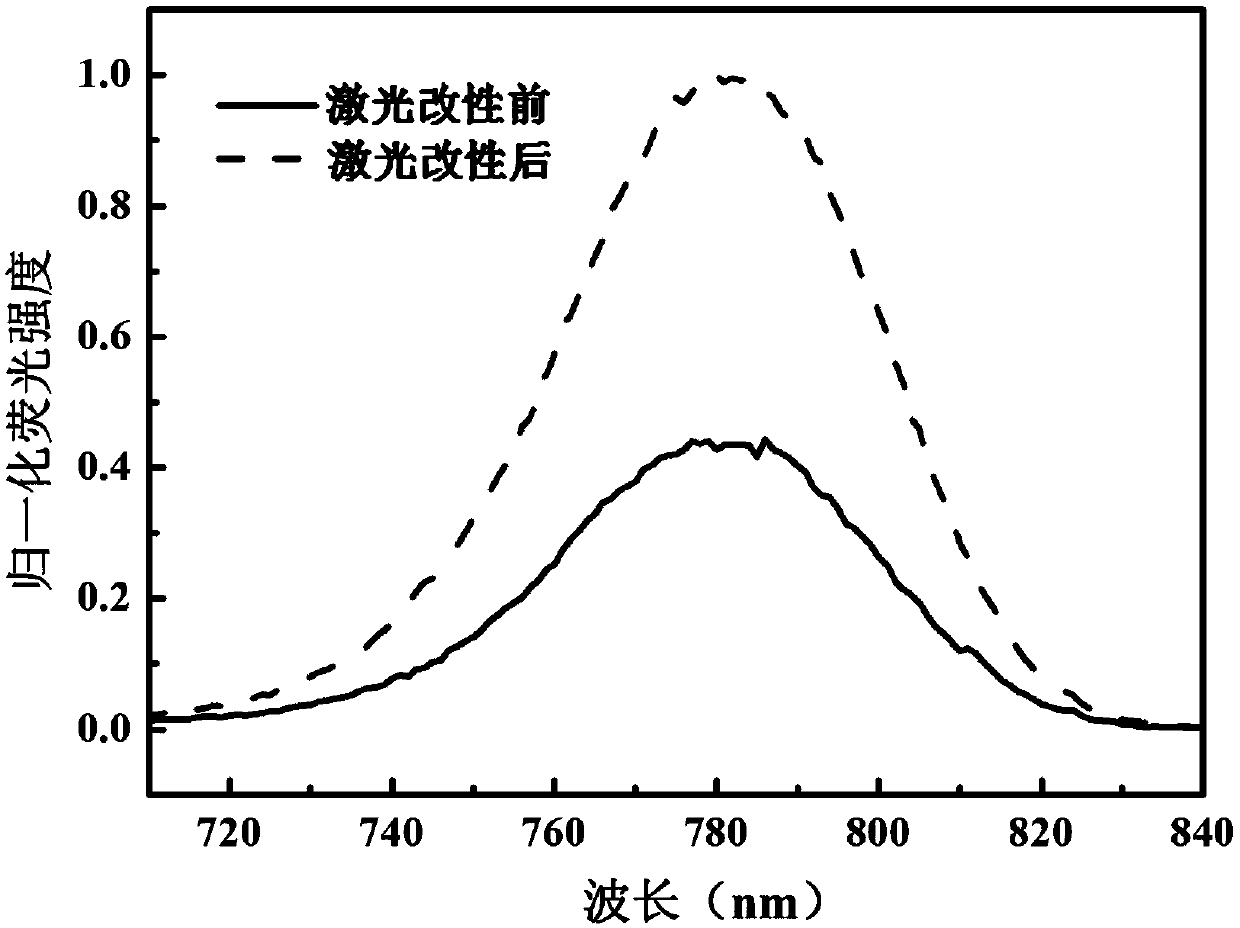

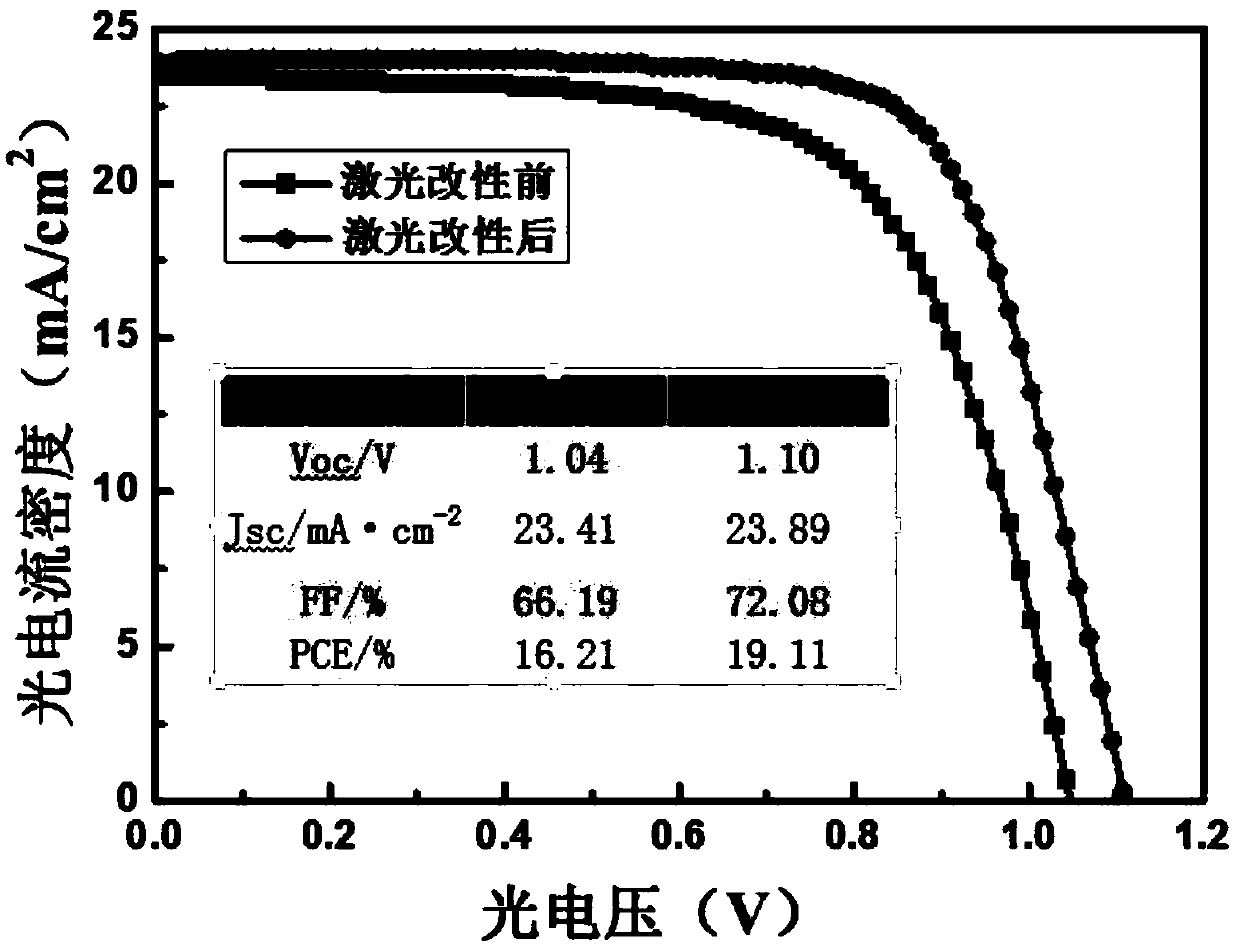

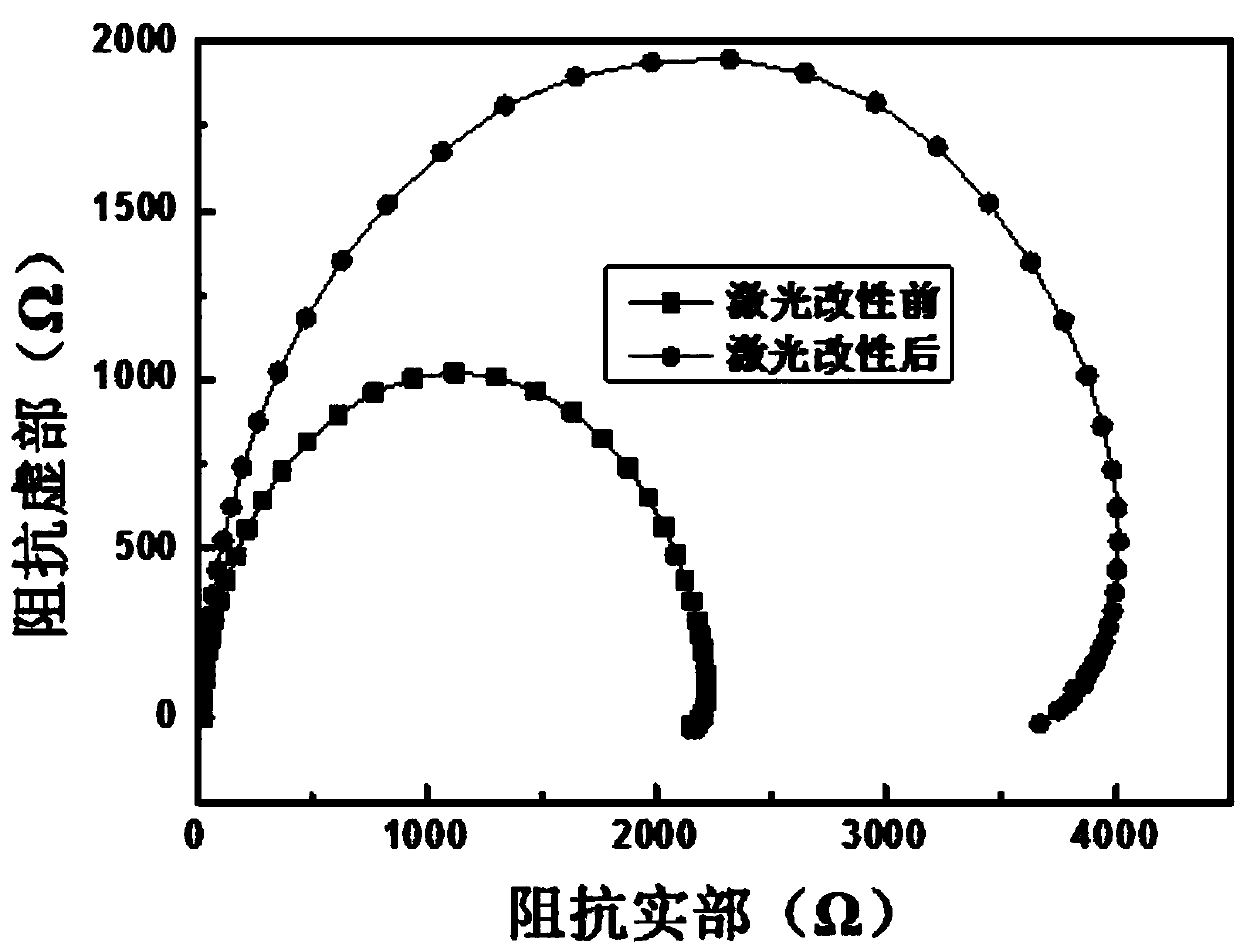

[0035] (3)CH 3 NH 3 PB 3 Laser surface modification of thin films: e.g. Figure 4 As shown, the prepared CH 3 NH 3 PB 3 The perovskite film 102 is placed on the conveyor belt 101, and the 308nm XeCl excimer laser beam 103 is irradiated on the CH from top to bottom. 3 NH 3 PB 3 on the perovskite film 102. 308nm XeCl excimer laser beam 103 spot size 80mm×5mm, energy density 500μJ / cm 2 , the laser wor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com