A battery module rapid assembly and rapid heat dissipation structure

A battery module and heat dissipation structure technology, which is applied to battery pack parts, structural parts, battery electrodes, etc., can solve problems such as the reliability of the joint connection being susceptible to vibration, difficulty in disassembly and maintenance, and the influence of heat generation on the joint, so as to achieve a simple assembly process Convenience, low module weight, and avoid damage to the joints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific embodiments of the present invention will be described in further detail below by describing the embodiments with reference to the accompanying drawings, so as to help those skilled in the art have a more complete, accurate and in-depth understanding of the inventive concepts and technical solutions of the present invention.

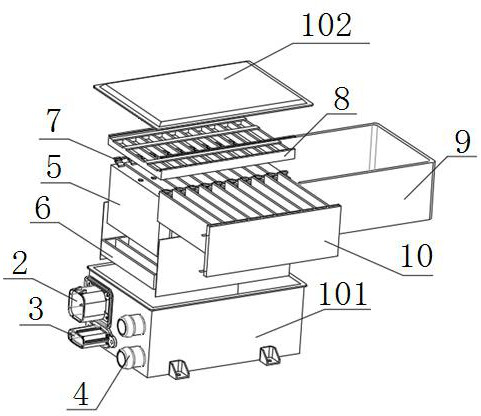

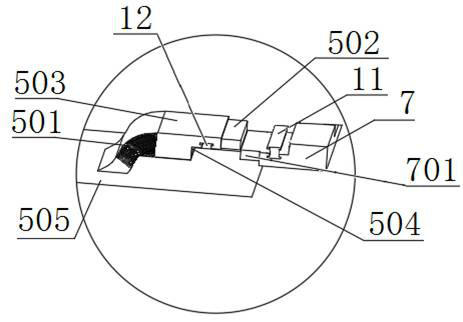

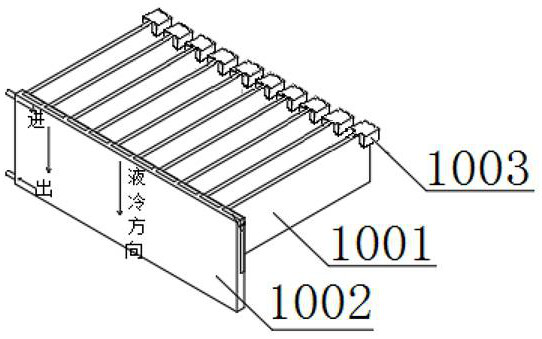

[0027] Such as Figure 1-6 As shown, the present invention provides a rapid assembly and rapid heat dissipation structure of a battery module, including a battery case 1, a bus bar 7, a heat dissipation assembly 10 and a plurality of single cells 5, and the electrode structure of the single cells 5 includes electrode The head 502, the flexible conductive part 501 and the electrode sleeve 503, the flexible conductive part 501 is a multi-layer aluminum foil with a laminated structure.

[0028]The electrode sleeve 503 is set outside the electrode head 502. One end of the electrode head 502 is exposed from the electrode sleeve 503 and con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com