End supporting joint structure and construction method of detachable steel bar truss plate

A technology of reinforced trusses and supporting nodes, which is applied in the direction of floors, building components, building structures, etc., can solve the problems of heavy steel grid truss combined formwork, high processing accuracy requirements, complex installation nodes, etc., and achieve simple and easy splicing and dismantling Good operation, anti-seismic and impact resistance, efficient and fast laying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

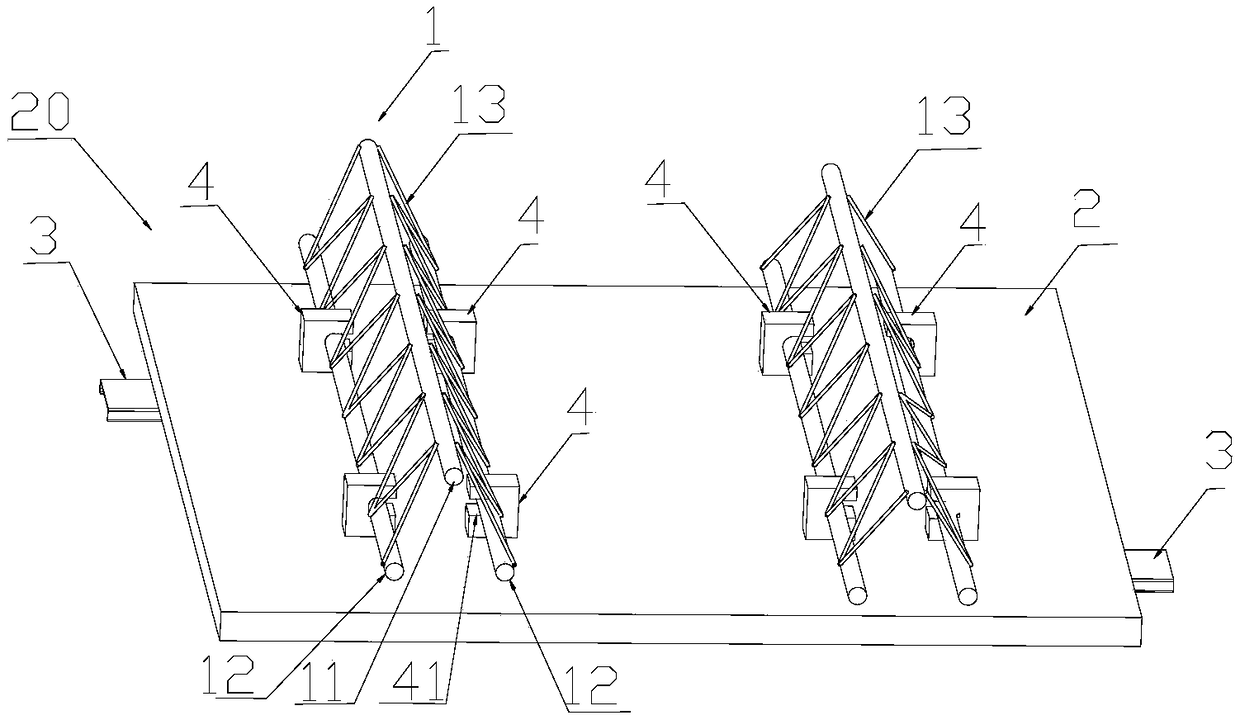

[0047] Such as figure 1 , figure 2A detachable steel truss slab 20 is shown, which includes a steel truss 1 , a connecting piece 4 , a floor deck 2 and a supporting piece 3 . The steel bar truss 1 includes an upper chord steel bar 11 and two lower chord steel bars 12 , and the two lower chord steel bars 12 are respectively welded and connected to the upper chord steel bars 11 through web steel bars 13 . The two lower chord steel bars 12 are connected with the connecting piece 4 relative to each other. The connecting piece 4 includes a slot 41 through the connecting piece 4 with a side opening, and a threaded hole is provided at the lower end of the connecting piece 4 . The connectors 4 are clamped on the two lower chord steel bars 12 in pairs, and each pair of connectors 4 is arranged longitudinally on the steel bar truss 1 .

[0048] figure 1 The span of the shown detachable steel truss slab 20 can be designed according to requirements, generally 1-3m, and its width is t...

Embodiment 2

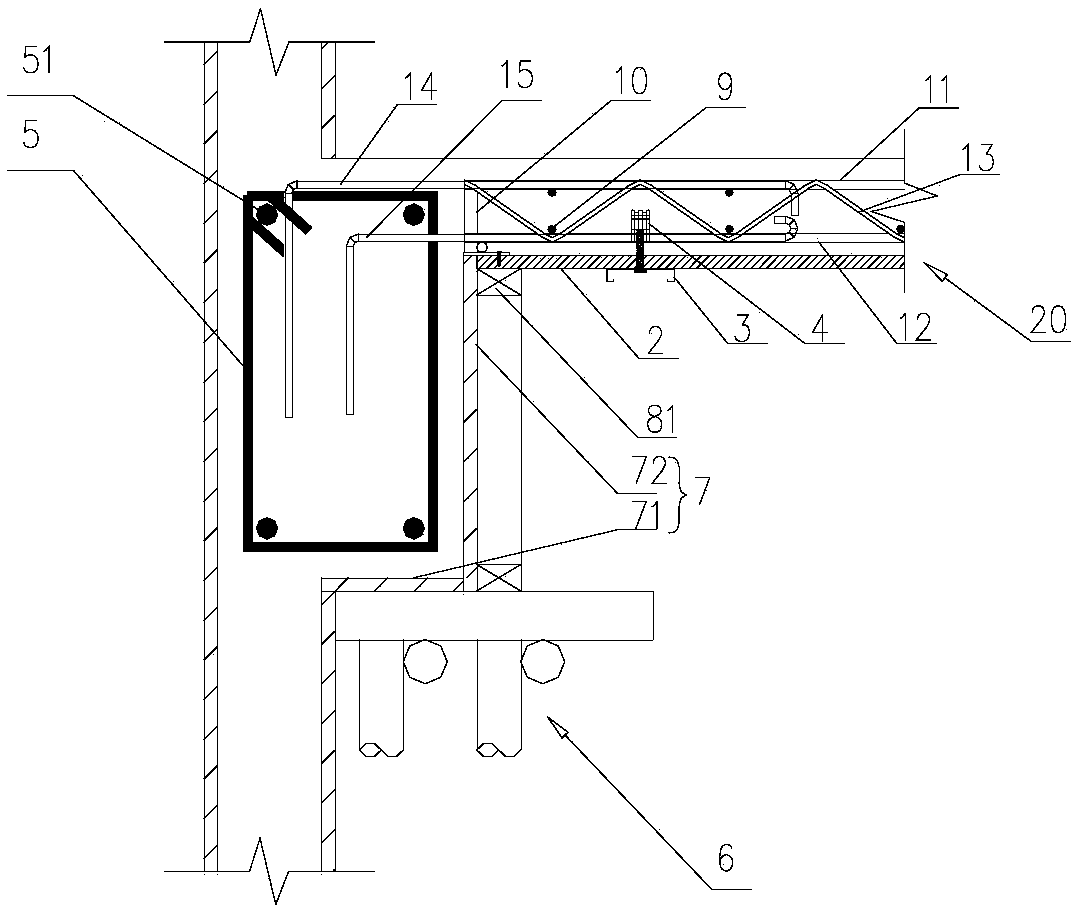

[0080] Such as Figure 7As shown, the difference between this embodiment and Embodiment 1 is that the frame structure 5 is a frame structure wall, so the frame structure 5 does not need a support frame to support it, and the frame structure 5 is provided with a frame formwork 7, so The outer side of the frame template 7 is erected with a first support member 81 , and the upper end of the first support member 81 is in contact with the steel bar truss plate 20 . The ends of the anchor bars 14 and 15 are bent and extend into the frame structure 5 .

Embodiment 3

[0082] Such as Figure 11 As shown, the difference between this embodiment and the above-mentioned embodiment is that steel bar truss plates 20 are respectively arranged on both sides of the frame structure 5, and the steel bar truss plates 20 on both sides of the frame structure 5 are respectively provided with anchor ribs 14A, 15A, and anchored Ribs 14B, 15B. The anchor ribs 14B, 15B are located between the upper and lower ribs 51 of the frame structure 5 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com