Automatic detection device and method for roller surface of roller press

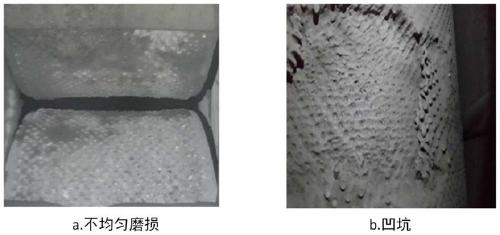

A technology of automatic detection device and roller press, which is applied in the direction of measuring device, image analysis, instrument, etc., can solve the problem of low detection accuracy of the detection device, and achieve the effect of solving the low detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0094] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention clearer, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention. Obviously, the described embodiments It is a part of embodiments of the present invention, but not all embodiments.

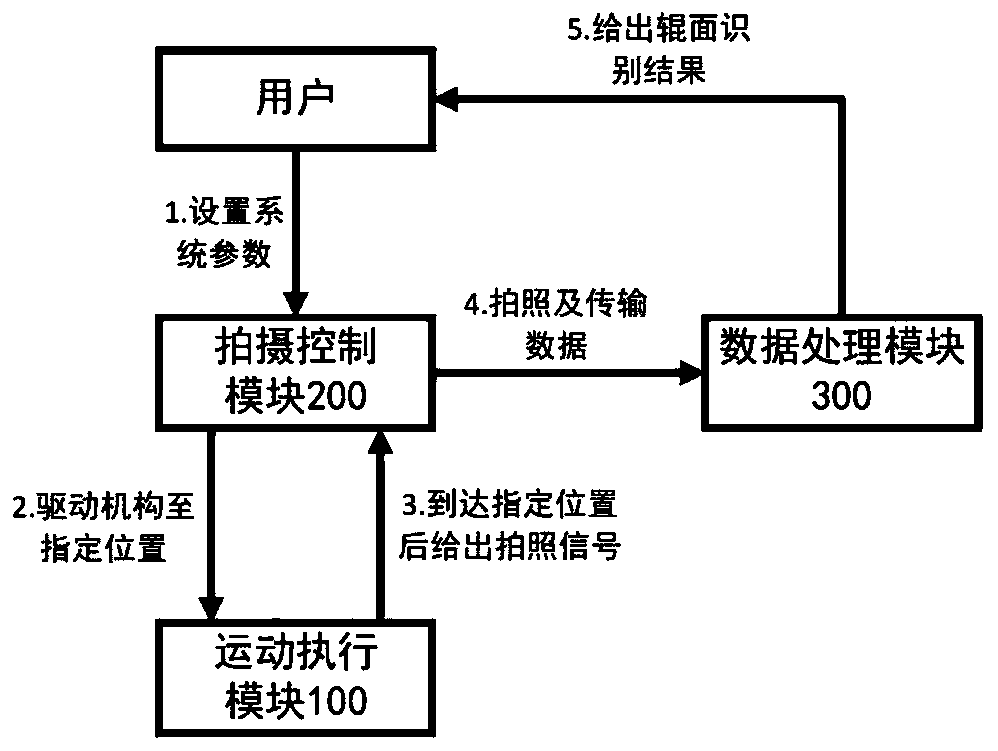

[0095] like image 3 and Figure 4 As shown, the automatic detection device for the roll surface of the roller press described in this embodiment mainly includes three major components: a motion execution module 100 , a shooting control module 200 , and a data processing module 300 .

[0096] like Figure 4 , Figure 5 and Image 6 shown:

[0097] The motion execution module 100 includes the following components: a support frame 101, a lead screw base 102, a lead screw 103, a ball 104, a wire drag 105, an organ cover 106, a camera support plate 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com