Preparation method for ultra-coarse tungsten carbide hard alloy containing trace cobalt

A technology of cemented carbide and tungsten carbide, which is applied in the field of high-hardness cemented carbide and high-strength preparation. It can solve the problems of fracture toughness and hardness contradiction, achieve uniform composition, improve comprehensive performance, and increase density.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

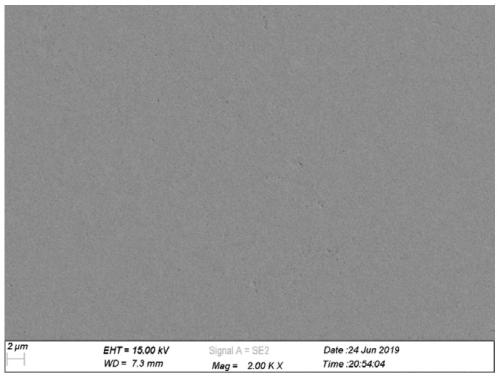

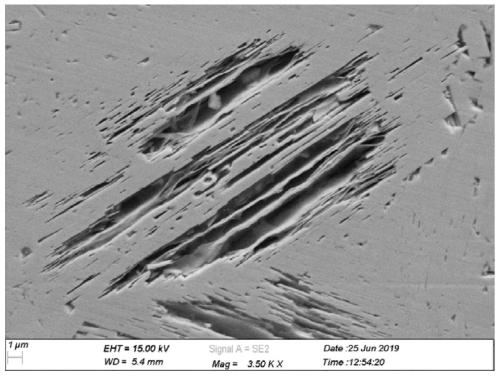

Image

Examples

Embodiment 1

[0030] The ultra-coarse WC cemented carbide composite material of the present embodiment is carried out as follows:

[0031] 1. Select WC powder with a particle size of 20 μm, nano WC-6Co composite powder with a grain size ≤ 200 nm, and cobalt powder with an average particle size of 3 μm. According to the composition of the required WC cemented carbide, weigh coarse-grained WC powder and nano-WC-6Co composite powder, the mass ratio of the two is 3:1, and add 4wt% Co, and use a mixer to mix mechanically for 2 hours to obtain a mixed Uniform cemented carbide mixture powder; according to the required product size, weigh a certain amount of composite powder;

[0032] 2. Fill the cemented carbide mixture powder weighed in step 1 into the graphite mold covered with graphite paper; use a manual hydraulic press to pre-press the graphite mold filled with the composite powder, and the pressure is ~10MPa;

[0033] 3. Wrap ~5mm thick carbon felt on the periphery of the graphite mold fill...

Embodiment 2

[0040] The ultra-coarse WC cemented carbide composite material of the present embodiment is carried out as follows:

[0041] 1. Select WC powder with a particle size of 20 μm, nano WC-6Co composite powder with a grain size ≤ 200 nm, and cobalt powder with an average particle size of 3 μm. According to the composition of the required WC cemented carbide, weigh coarse-grained WC powder and nano-WC-6Co composite powder, the mass ratio of the two is 3:1, and add 4wt% Co, and use a mixer to mix mechanically for 2 hours to obtain a mixed Uniform cemented carbide mixture powder; according to the required product size, weigh a certain amount of composite powder;

[0042] 2. Fill the cemented carbide mixture powder weighed in step 1 into the graphite mold covered with graphite paper; use a manual hydraulic press to pre-press the graphite mold filled with the composite powder, and the pressure is ~10MPa;

[0043] 3. Wrap ~5mm thick carbon felt on the periphery of the graphite mold fill...

Embodiment 3

[0050] The ultra-coarse WC cemented carbide composite material of the present embodiment is carried out as follows:

[0051] 1. Select WC powder with a particle size of 20 μm, nano WC-6Co composite powder with a grain size ≤ 200 nm, and cobalt powder with an average particle size of 3 μm. According to the composition of the required WC cemented carbide, weigh coarse-grained WC powder and nano-WC-6Co composite powder, the mass ratio of the two is 3:1, and add 4wt% Co, and use a mixer to mix mechanically for 2 hours to obtain a mixed Uniform cemented carbide mixture powder; according to the required product size, weigh a certain amount of composite powder;

[0052] 2. Fill the cemented carbide mixture powder weighed in step 1 into the graphite mold covered with graphite paper; use a manual hydraulic press to pre-press the graphite mold filled with the composite powder, and the pressure is ~10MPa;

[0053] 3. Wrap ~5mm thick carbon felt on the periphery of the graphite mold fill...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com