Dendrobium polysaccharide extract, and preparation method thereof

A technology for dendrobium polysaccharide and extract is applied in the field of dendrobium polysaccharide extract and its preparation, which can solve the problems of undisclosed yield of dendrobium polysaccharide, high safety requirements, complicated process operation, etc. The effect of large processing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

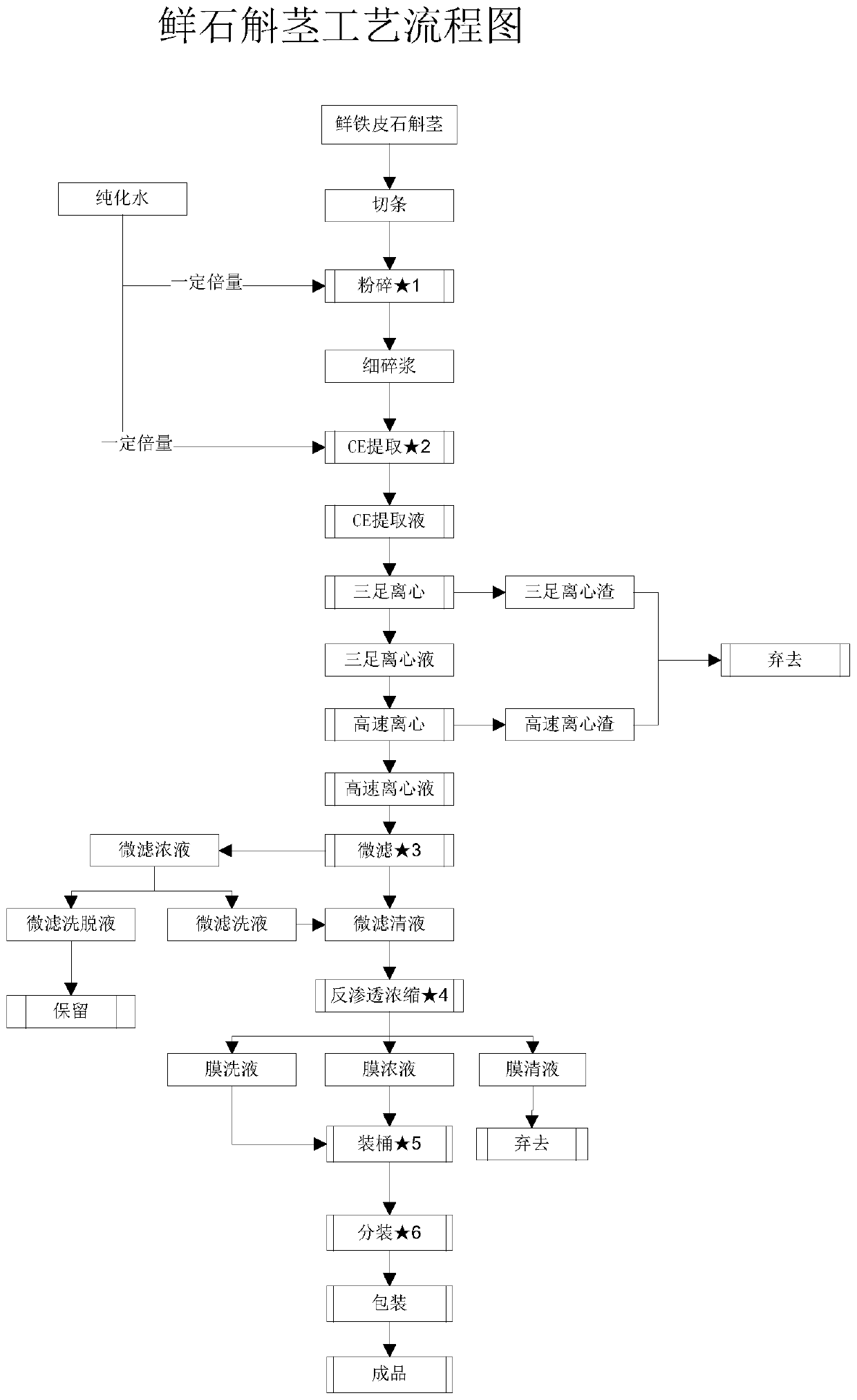

[0037] This embodiment is a preparation method of Dendrobium polysaccharide extract, the steps are as follows (process flow chart see figure 1 ):

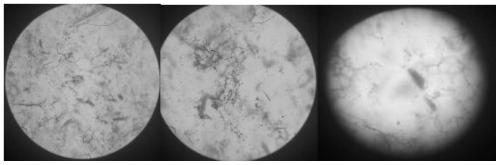

[0038] 1. cut into strips: fresh dendrobium stem (its microscope image is as figure 2 shown) cut into small pieces between 0.5cm and 2cm;

[0039] 2. Pulverization: Use a high-efficiency turbo pulverizer with a pore size of 0.8mm to pulverize the fresh dendrobium stem segments into a fine pulp by adding a certain amount of purified water;

[0040] 3. Mixing and pulping: put the crushed fresh Dendrobium finely crushed pulp and purified water in the mixing tank of the high-speed mixer, stir and mix evenly and control the temperature not to exceed 25°C;

[0041] 4. Extraction: Add the mixed solution into the buffer tank of the high pressure difference continuous extractor, control the extraction force range to 25-35MPa, and extract the temperature at 20°C; collect the discharge to obtain the mixed material liquid; the high pressure...

Embodiment 2

[0051] This example is a preparation method of Dendrobium polysaccharide extract, the steps of which are the same as Example 1, the only difference is that in Step 4, the extraction pressure difference is controlled to be 10-20 MPa, and the extraction temperature is 35°C.

[0052] Specific steps are as follows:

[0053] 1. Cut into strips: Cut the fresh Dendrobium stems into small sections between 0.5cm and 2cm with a traditional Chinese medicine slicer;

[0054] 2. Pulverization: Use a high-efficiency turbo pulverizer with a pore size of 0.8mm to pulverize the fresh dendrobium stem segments into a fine pulp by adding a certain amount of purified water;

[0055] 3. Mixing and pulping: put the crushed fresh Dendrobium finely crushed pulp and purified water in the mixing tank of the high-speed mixer, stir and mix evenly and control the temperature not to exceed 25°C;

[0056] 4. Extraction: Add the mixed solution into the buffer tank of the high-pressure differential continuous...

Embodiment 3

[0065] This example is a preparation method of Dendrobium polysaccharide extract, the steps of which are the same as those of Example 1, the only difference is that in Step 4, the extraction pressure difference is controlled to be 40-50 MPa, and the extraction temperature is 15°C.

[0066] Specific steps are as follows:

[0067] 1. Cut into strips: Cut the fresh Dendrobium stems into small sections between 0.5cm and 2cm with a traditional Chinese medicine slicer;

[0068] 2. Pulverization: Use a high-efficiency turbo pulverizer with a pore size of 0.8mm to pulverize the fresh dendrobium stem segments into a fine pulp by adding a certain amount of purified water;

[0069] 3. Mixing and pulping: put the crushed fresh Dendrobium finely crushed pulp and purified water in the mixing tank of the high-speed mixer, stir and mix evenly and control the temperature not to exceed 25°C;

[0070] 4. Extraction: Add the mixed solution into the buffer tank of the high-pressure differential c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com