Compound enzyme preparation for oil extraction and oil extraction method

A compound enzyme preparation and oil extraction technology, which is applied in the production of fat oil/fat, hydrolase, and fat production, can solve the problems of high benefit cost, high oil moisture content, easy oxidative rancidity, etc. Guaranteed quality, good for digestion and absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

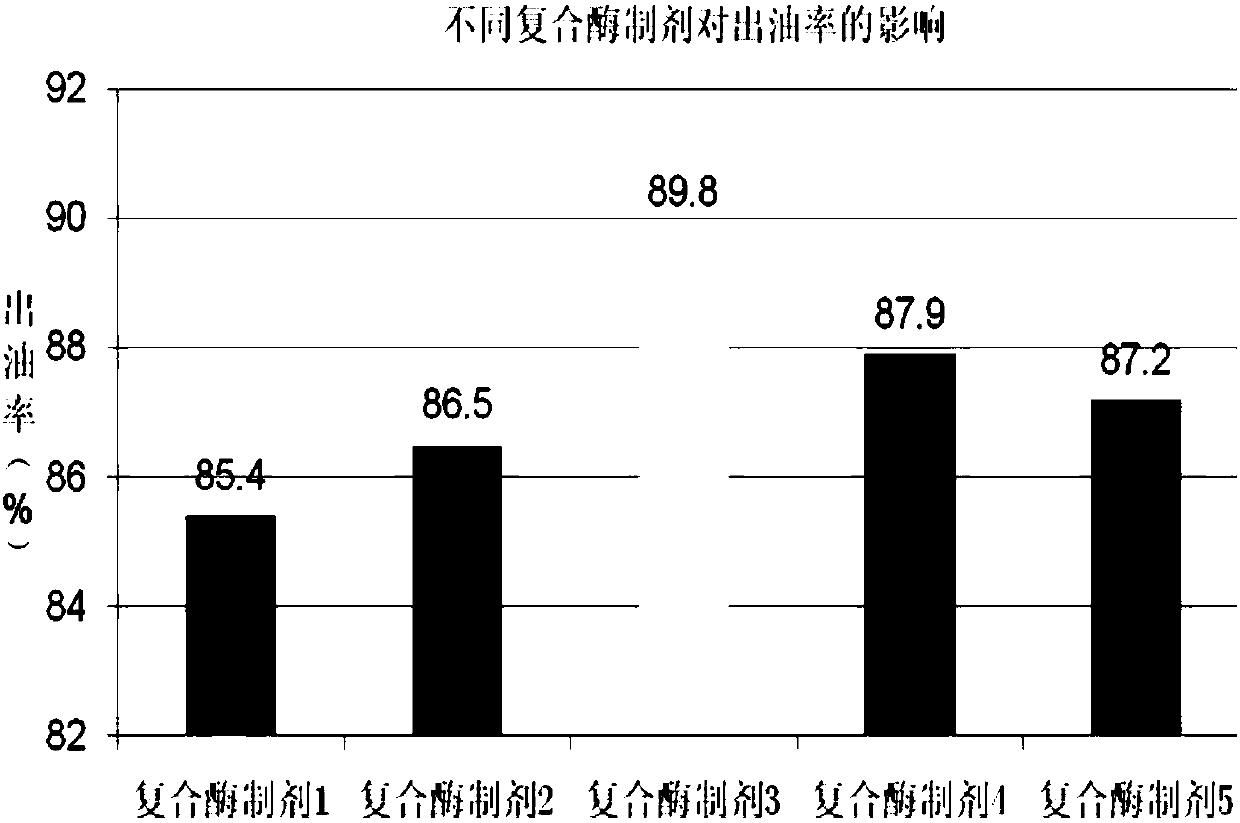

[0032] The compound enzyme preparation (hereinafter referred to as compound enzyme preparation 1) used for oil extraction in the present embodiment, by weight, said compound enzyme preparation comprises: 1 part of neutral protease, 1 part of alkaline protease, 0.2 part of flavor enzyme , 0.2 parts of collagenase, and 2 parts of carrier. Wherein, the carrier includes one or more mixtures of rice bran, bran, bamboo powder or cornstarch, thus, the carrier can have good versatility; the fat comes from slaughter leftovers (such as livestock and poultry Slaughter leftovers produced during the slaughtering process).

[0033] The method for utilizing the above-mentioned compound enzyme preparation 1 to carry out oil extraction comprises the following steps:

[0034] S1. Prepare the above compound enzyme preparation 1 for oil extraction; specifically, the preparation method of the compound enzyme preparation 1 includes:

[0035] S11. Firstly premix and dilute the flavor enzyme and co...

Embodiment 2

[0046] The only difference between this embodiment and Example 1 is that the compound enzyme preparation in this embodiment (hereinafter referred to as compound enzyme preparation 2), in parts by weight, said compound enzyme preparation comprises: 1 part of neutral protease, alkali 2 parts of protease, 0.2 part of flavor enzyme, 0.2 part of collagenase, 2 parts of carrier.

[0047] Calculated according to formula (1) in this embodiment, the oil yield of the raw material is 86.5%.

Embodiment 3

[0049] The only difference between this embodiment and Example 1 is that the compound enzyme preparation in this embodiment (hereinafter referred to as compound enzyme preparation 3), in parts by weight, said compound enzyme preparation comprises: 1 part of neutral protease, alkali 3 parts of protease, 0.2 part of flavor enzyme, 0.2 part of collagenase, 2 parts of carrier.

[0050] Calculated according to formula (1) in this embodiment, the oil yield of the raw material is 89.8%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com