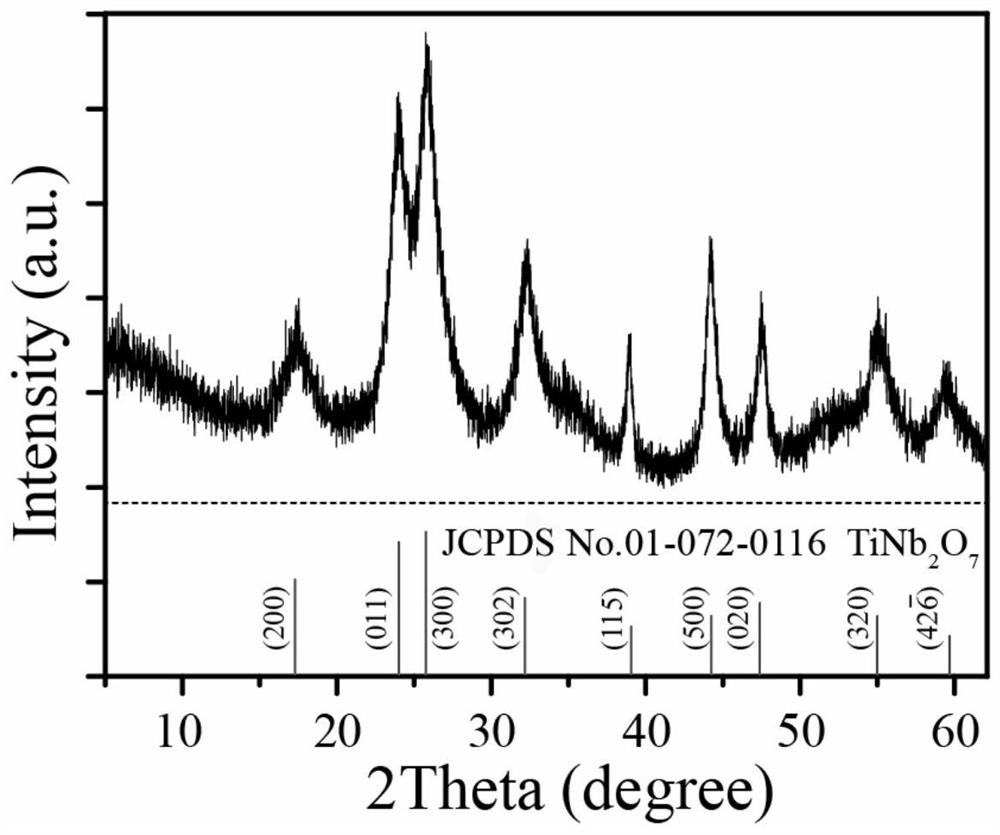

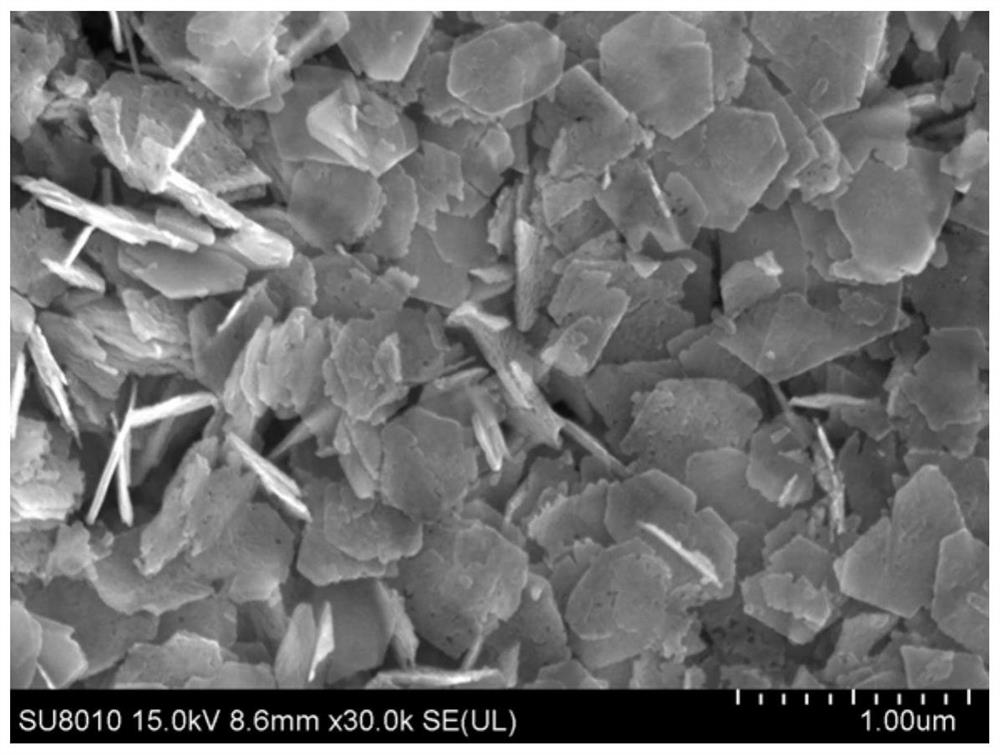

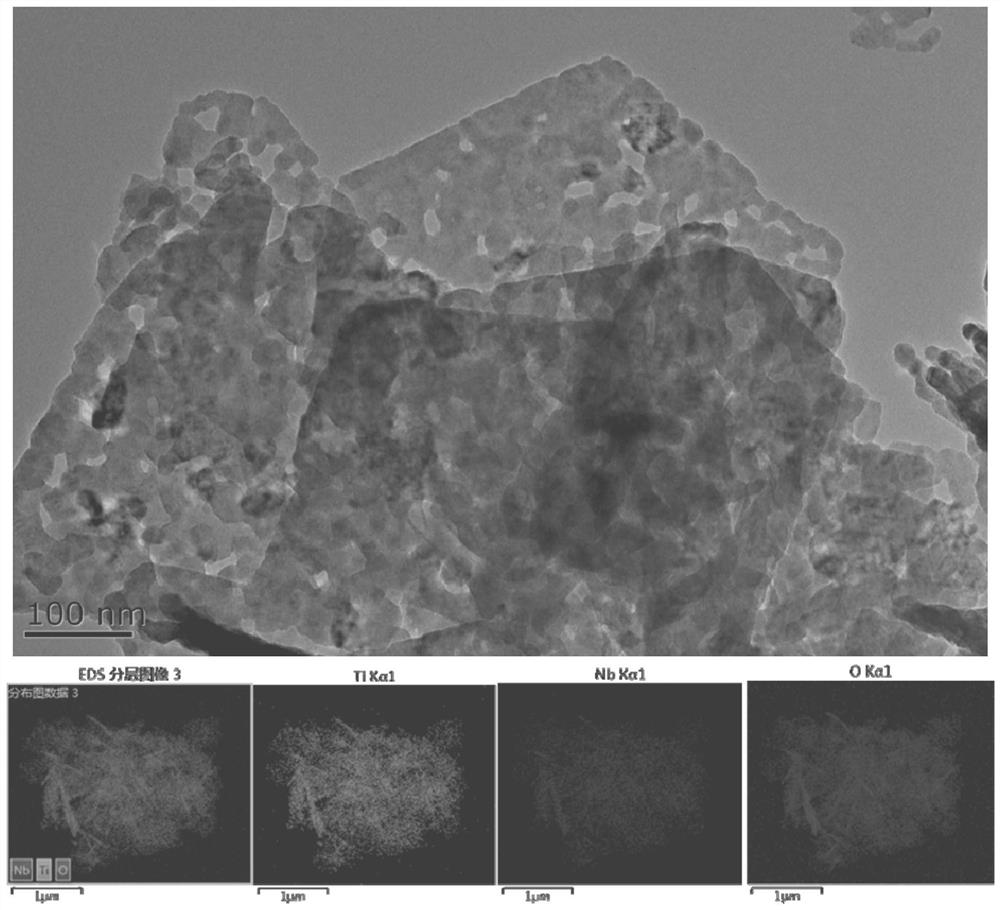

A kind of porous sheet tinb for negative electrode of lithium ion battery 2 o 7 Preparation methods of nanocrystals

A lithium-ion battery, flake-shaped technology, applied in battery electrodes, nanotechnology for materials and surface science, negative electrodes, etc., can solve problems such as uneven particle size distribution, fast capacity decay, and large particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] porous thin TiNb 2 o 7 The preparation method of nanocrystalline negative electrode material, concrete steps are as follows:

[0023] Step 1: Weigh 0.400g of niobium pentachloride and 0.252g of tetrabutyl titanate and add them into a mixed solution of 15mL of ethylene glycol and 15mL of isopropanol.

[0024] Step 2: Add 0.952 g of hexamethylenetetramine to the solution obtained in Step 1, mix and stir for 0.5 h, and the rotating speed is 500 r / min.

[0025] Step 3: The solution obtained in Step 2 was transferred to a stainless steel reaction kettle lined with polytetrafluoroethylene, placed in a constant temperature drying oven, and heated at 190° C. for 30 hours.

[0026] Step 4: After the reaction is completed, remove the oily liquid on the upper layer to obtain a white precipitate spread on the bottom, then wash with deionized water and ethanol separately and mix several times, and dry the obtained sample in a vacuum oven at 70°C 12h.

[0027] Step 5: Calcining t...

Embodiment 2

[0030] porous thin TiNb 2 o 7 The preparation method of nanocrystalline negative electrode material, concrete steps are as follows:

[0031] Step 1: Weigh 0.8g of niobium pentachloride and 0.504g of tetrabutyl titanate and add them into a mixed solution of 21mL of ethylene glycol and 42mL of isopropanol.

[0032] Step 2: Add 1.904 g of hexamethylenetetramine to the solution obtained in Step 1, mix and stir for 1 hour, and the rotating speed is 500 r / min.

[0033] Step 3: The solution obtained in Step 2 was transferred to a stainless steel reaction kettle lined with polytetrafluoroethylene, placed in a constant temperature drying oven, and heated at 180° C. for 36 hours.

[0034]Step 4: After the reaction is completed, remove the oily liquid on the upper layer to obtain a white precipitate spread on the bottom, then wash with deionized water and ethanol separately and mix several times, and dry the obtained sample in a vacuum oven at 70°C 12h.

[0035] Step 5: Calcining the...

Embodiment 3

[0037] porous thin TiNb 2 o 7 The preparation method of nanocrystalline negative electrode material, concrete steps are as follows:

[0038] Step 1: Weigh 0.400g of niobium pentachloride and 0.252g of tetrabutyl titanate and add them into a mixed solution of 18mL of ethylene glycol and 9mL of isopropanol.

[0039] Step 2: Add 0.952 g of hexamethylenetetramine to the solution obtained in Step 1, mix and stir for 0.5 h, and the rotating speed is 400 r / min.

[0040] Step 3: The solution obtained in Step 2 was transferred to a stainless steel reaction kettle lined with polytetrafluoroethylene, placed in a constant temperature drying oven, and heated at 200° C. for 24 hours.

[0041] Step 4: After the reaction is completed, remove the oily liquid on the upper layer to obtain a white precipitate spread on the bottom, then wash with deionized water and ethanol separately and mix several times, and dry the obtained sample in a vacuum oven at 70°C 12h.

[0042] Step 5: Calcinate th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com