A non-toxic and resourceful treatment process for barium slag

A treatment process and resource recovery technology, applied in the field of barium slag treatment process, can solve the problems of high cost, high cost, hazardous waste, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

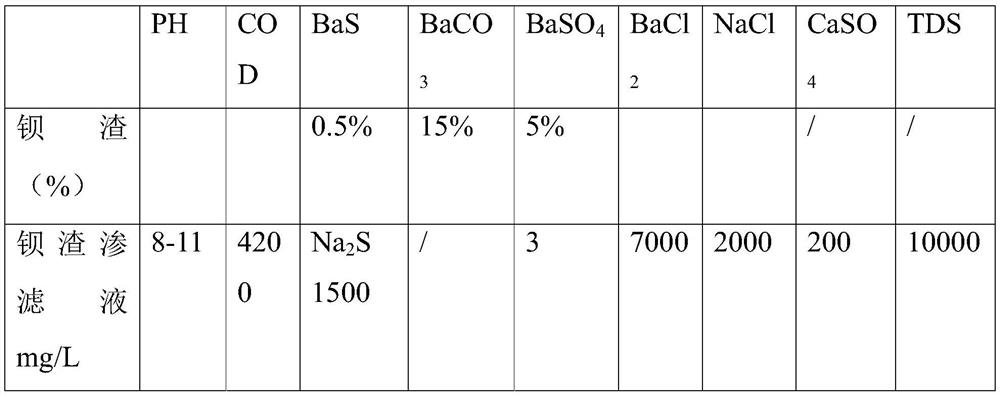

Method used

Image

Examples

Embodiment 1

[0071] A non-toxic, resource-based treatment process for barium slag, comprising the steps of:

[0072] (1) Water-soluble: Soak the barium slag with clear water and / or the leachate of the barium slag field until the content of BaS in the barium slag is lower than 0.1%;

[0073] (2) Acid soluble: Soak the water-soluble barium slag in acid medium until the BaCO in the barium slag 3 The content of is less than 3%, and the acid medium includes hydrochloric acid;

[0074] (3) Detoxification: Soak the acid-dissolved barium slag in desulfurization wastewater until the content of BaS in the barium slag is lower than 1ppm, and then press filter to obtain a non-toxic barium slag product.

[0075] Wherein, in the step (1) water dissolving, the supernatant produced by soaking the barium slag is used to recover and produce BaS, and the mass fraction of BaS in the supernatant is 10%.

[0076] Wherein, in the step (2) acid dissolution, the supernatant produced by soaking the barium slag is...

Embodiment 2

[0082] A non-toxic, resource-based treatment process for barium slag, comprising the steps of:

[0083] (1) Water-soluble: Soak the barium slag with clear water and / or the leachate of the barium slag field until the content of BaS in the barium slag is lower than 0.1%;

[0084] (2) Acid soluble: Soak the water-soluble barium slag in acid medium until the BaCO in the barium slag 3 The content of is less than 3%, and the acid medium includes hydrochloric acid;

[0085] (3) Detoxification: Soak the acid-dissolved barium slag in desulfurization wastewater until the content of BaS in the barium slag is lower than 1ppm, and then press filter to obtain a non-toxic barium slag product.

[0086] Wherein, in the step (1) water dissolving, the supernatant produced by soaking the barium slag is used to recover and produce BaS, and the mass fraction of BaS in the supernatant is 8%.

[0087]Wherein, in the step (2) acid dissolution, the supernatant produced by soaking the barium slag is u...

Embodiment 3

[0093] A non-toxic, resource-based treatment process for barium slag, comprising the steps of:

[0094] (1) Water-soluble: Soak the barium slag with clear water and / or the leachate of the barium slag field until the content of BaS in the barium slag is lower than 0.1%;

[0095] (2) Acid soluble: Soak the water-soluble barium slag in acid medium until the BaCO in the barium slag 3 The content of is less than 3%, and the acid medium includes hydrochloric acid;

[0096] (3) Detoxification: Soak the acid-dissolved barium slag in desulfurization wastewater until the content of BaS in the barium slag is lower than 1ppm, and then press filter to obtain a non-toxic barium slag product.

[0097] Wherein, in the step (1) of dissolving in water, the supernatant produced by soaking the barium slag is used to recover and produce BaS, and the mass fraction of BaS in the supernatant is 9%.

[0098] Wherein, in the step (2) acid dissolution, the supernatant produced by soaking the barium sl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com