A kind of synthetic method of semigossypol, gossypol and their analogs

A synthetic method, the technology of semi-gossypol, which is applied in the field of gossypol and their analogs, and the synthesis of semi-gossypol, can solve the problem of single product structure, difficult synthesis of semi-gossypol and gossypol analogs, and inability to obtain semi-gossypol and gossypol Gossypol analogs and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

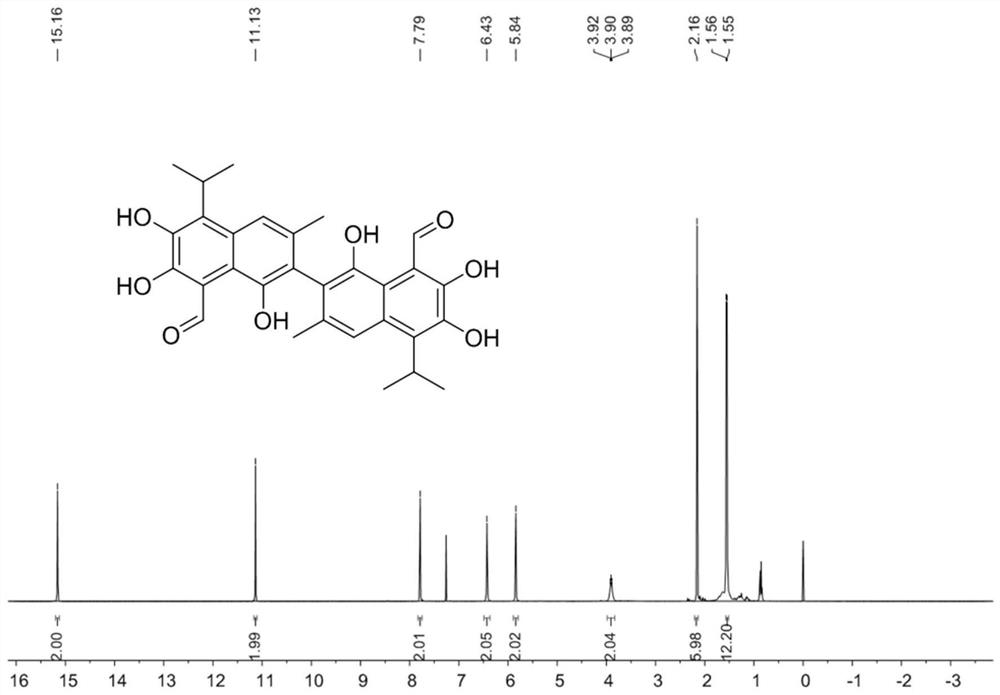

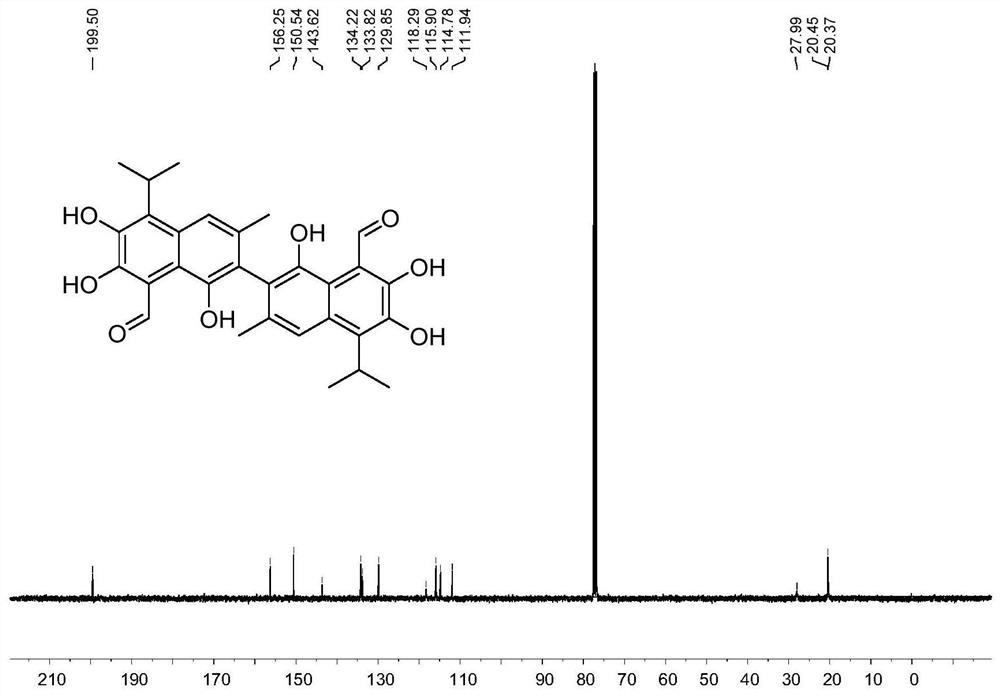

[0142] The synthesis of gossypol (compound X VI-1), synthetic route is as follows:

[0143]

[0144] Concrete synthetic steps are as follows:

[0145] (1) Add 6.8g of compound I-1 isopropyl maltol, 3 equivalents of potassium carbonate and 1.2 equivalents of propargyl bromide to 150 ml of acetonitrile, heat at 80°C for 14 hours, cool to room temperature, filter, After the solvent was evaporated under reduced pressure, 8.0 g of compound II-1 was obtained by column chromatography with a yield of 94%. 1 H NMR (400MHz, CDCl 3 )δ7.71(d, J=5.6Hz, 1H), 6.35(d, J=5.6Hz, 1H), 4.91(d, J=2.4Hz, 2H), 3.54(hept, J=7.0Hz, 1H) , 2.46(t, J=2.4Hz, 1H), 1.23(d, J=7.0Hz, 6H). 13 C NMR (101MHz, CDCl 3 )δ175.19, 167.55, 153.96, 141.01, 116.92, 79.21, 75.76, 58.72, 27.21, 19.92.HR-MS(ESI)calcd.for[C 11 h 12 o 3 +Na] + 215.0679, found: 215.0678.

[0146] (2) 8.0 g of compound II-1, 3 equivalents of potassium carbonate, 1.5 equivalents of allyl bromide, 0.1 equivalents of cuprous iodide an...

Embodiment 2

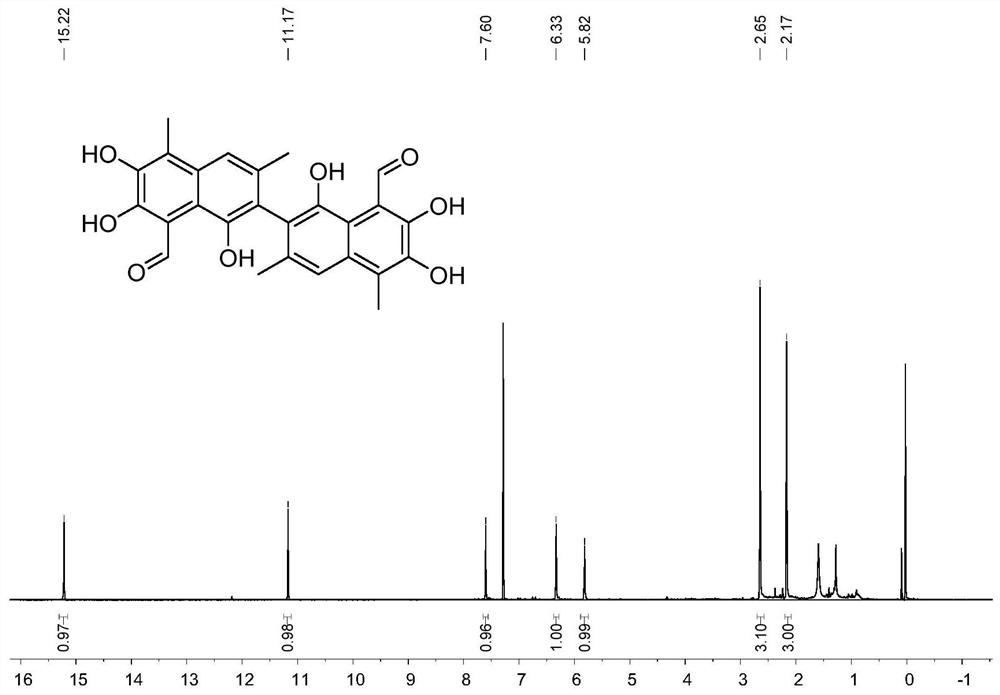

[0164] The synthesis of methyl-gossypol (compound XVI-2), the synthetic route is as follows:

[0165]

[0166] Concrete synthetic steps are as follows:

[0167] (1) Add 15g of compound I-2 methyl maltol, 3 equivalents of potassium carbonate and 1.2 equivalents of propargyl bromide to 300 ml of acetonitrile, heat at 80°C for 12 hours, cool down to room temperature, and use a short silica gel column After filtering and distilling off the solvent under reduced pressure, 17.2 g of compound II-2 was obtained by column chromatography with a yield of 88%. 1 H NMR (400MHz, CDCl3) δ7.63(d, J=5.6Hz, 1H), 6.39-6.30(m, 1H), 4.88(d, J=2.4Hz, 2H), 2.44(t, J=2.4Hz , 1H), 2.38(s, 3H). 13 C NMR (101MHz, CDCl3) δ174.84, 160.82, 153.77, 143.02, 117.29, 79.19, 75.75, 58.85, 15.42. HR-MS (ESI) calcd.for[C 9 h 8 o 3 +Na] + 187.0366, found 187.0367.

[0168] (2) 17.2 g of compound II-2, 3 equivalents of potassium carbonate, 1.5 equivalents of allyl bromide, 0.1 equivalents of cuprous iodid...

Embodiment 3

[0186] In Example 1, in step (1), 1.0 equivalent of potassium carbonate was added, 1.0 equivalent of propargyl bromide was added, and the reaction was carried out at 40° C., and the rest of the reaction conditions were unchanged. The yield of compound II-1 was 80%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com