Method for Synthesizing Methanol

A technology for synthesizing methanol and methanol, applied in chemical instruments and methods, hydrogen/synthesis gas production, preparation of organic compounds, etc., can solve problems such as reducing methanol yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

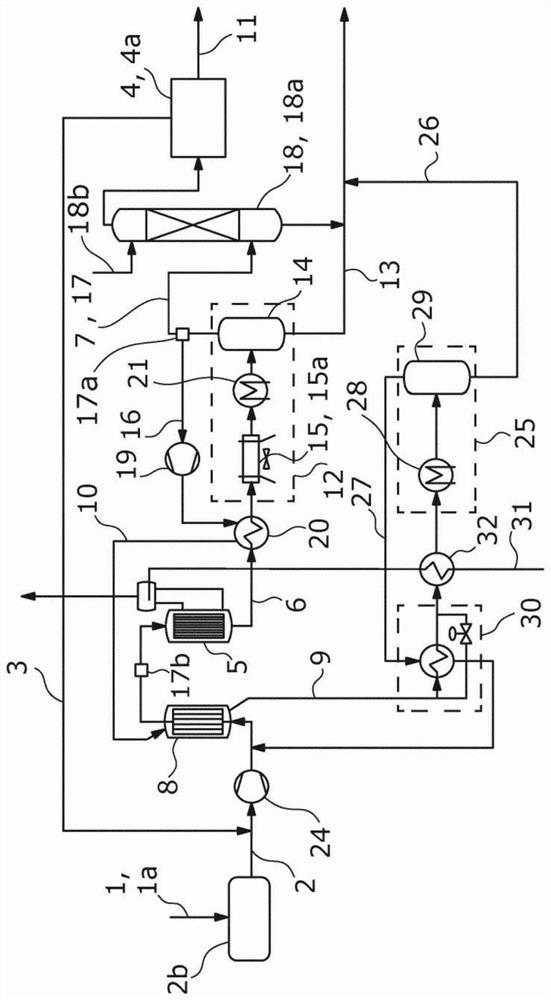

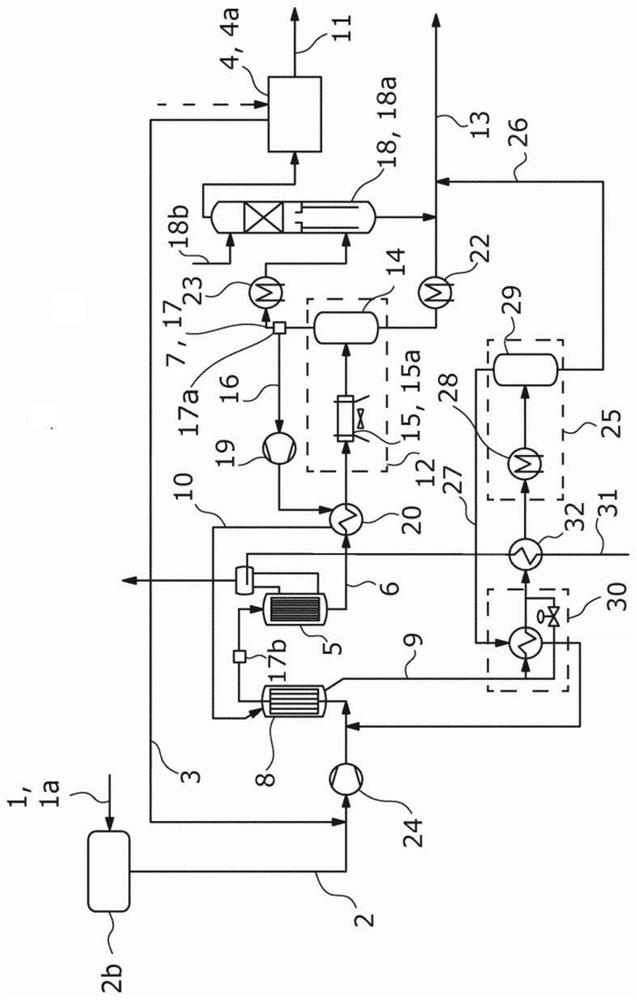

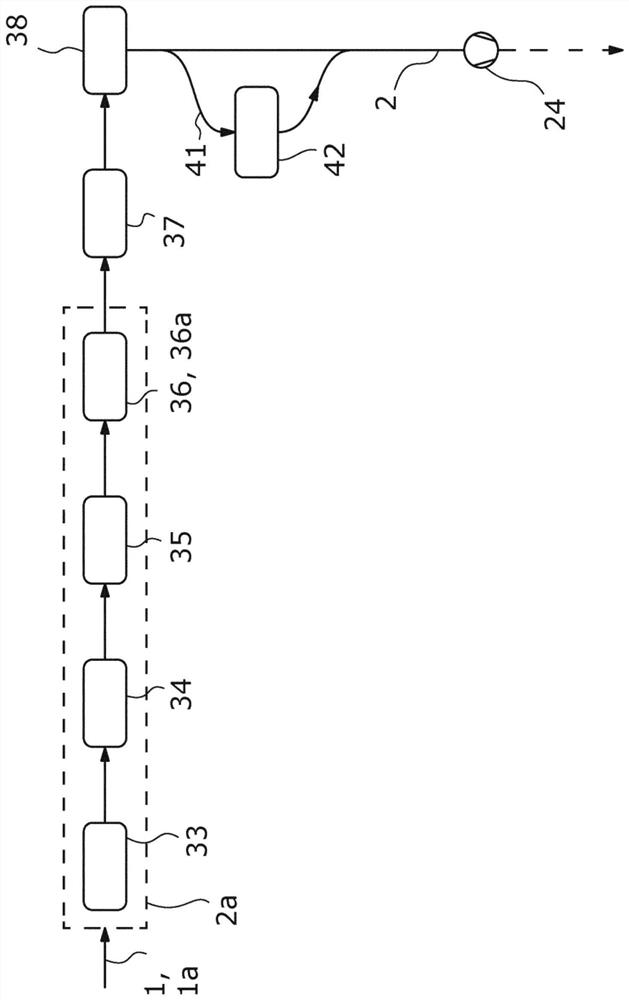

[0022] The proposed method was used to synthesize methanol and first referred to figure 1 and figure 2 Examples of the description. Unless stated otherwise, the following statements also refer to these two exemplary embodiments. In the proposed process, the hydrogen-comprising stream 3 from the hydrogen recovery stage 4 is fed to a synthesis gas stream 2 comprising hydrogen and carbon oxides, and the synthesis gas stream 2 is fed to the main reactor stage 5 . In principle, the synthesis gas flow 2 can originate from any source, however, it is preferably obtained from the carbon-containing energy carrier flow 1 , wherein the manner in which the synthesis gas flow 2 is thus obtained can again be arbitrary in principle. Next and especially with reference to image 3 and Figure 4 Details concerning the energy carrier flow 1 and the obtaining of the synthesis gas flow 2 therefrom are discussed in more detail in a specific example. exist figure 1 In the example of , the obta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com