A kind of surface treatment method of tinb alloy

A surface treatment and alloy technology, applied in the field of nanomaterials and biomaterials, can solve the problems of complex preparation process, focus only on, and deteriorate the mechanical properties of titanium and its alloy substrates, and achieve simple preparation steps, large roughness, and excellent biological properties. active effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

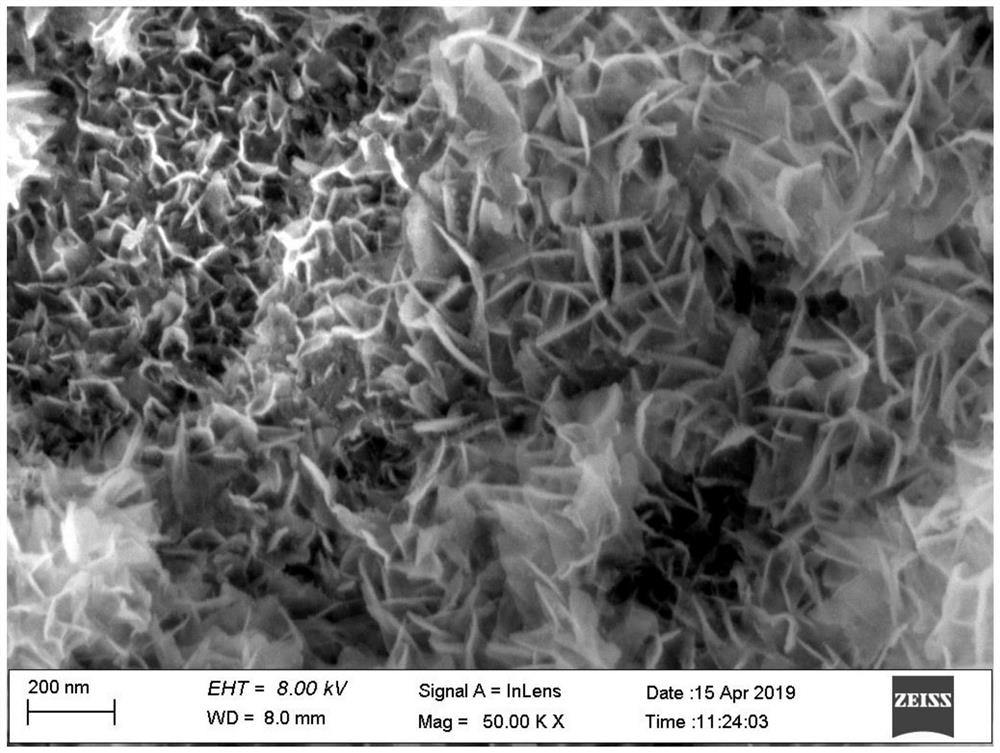

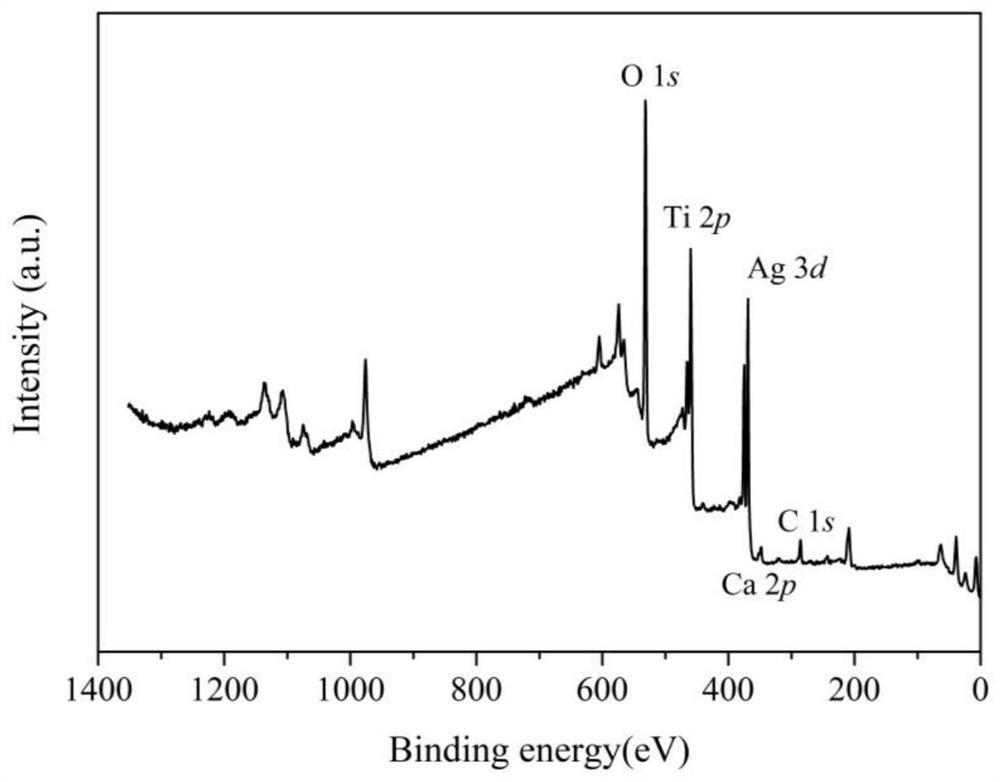

[0029] Step 1. Polish the TiNb alloy sheet with a size of 10mm×10mm×1mm sequentially with 240#, 600# and 1400# water sandpaper, then place the polished TiNb alloy sheet in acetone for ultrasonic degreasing, and then use deionized After washing with water, dry naturally; the mass percentage of Nb in the TiNb alloy sheet is 20%, and the balance is Ti and other unavoidable impurities;

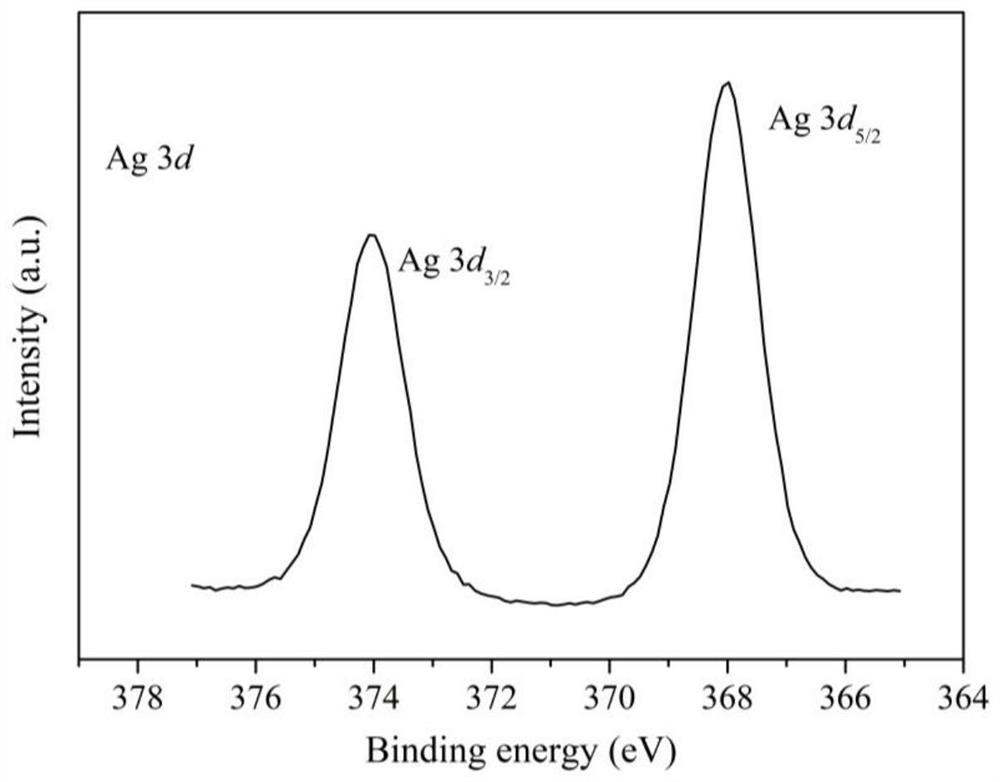

[0030] Step 2, silver nitrate and calcium nitrate are dissolved in the hydrogen peroxide solution to obtain a mixed solution; the hydrogen peroxide solution is commercial hydrogen peroxide with a mass percentage of 30%; the concentration of silver nitrate in the mixed solution is 8mmol / L, calcium nitrate The concentration is 3mmol / L;

[0031]Step 3, adding the mixed solution described in step 2 into the hydrothermal synthesis reaction kettle, then putting the air-dried TiNb alloy sheet in the step 1 into the hydrothermal synthesis reaction kettle, sealing the hydrothermal synthesis reaction kettle...

Embodiment 2

[0038] Step 1. Polish the TiNb alloy sheet with a size of 40mm×10mm×2mm sequentially with 240#, 600# and 1400# water sandpaper, then place the polished TiNb alloy sheet in acetone for ultrasonic degreasing, and then use deionized After washing with water, dry naturally; the mass percentage of Nb in the TiNb alloy sheet is 10%, and the balance is Ti and other unavoidable impurities;

[0039] Step 2, dissolving silver nitrate and calcium nitrate in hydrogen peroxide solution to obtain a mixed solution; the hydrogen peroxide solution is commercial hydrogen peroxide with a mass percentage of 30%; the concentration of silver nitrate in the mixed solution is 3mmol / L, calcium nitrate The concentration is 5mmol / L;

[0040] Step 3, adding the mixed solution described in step 2 into the hydrothermal synthesis reaction kettle, then putting the air-dried TiNb alloy sheet in the step 1 into the hydrothermal synthesis reaction kettle, sealing the hydrothermal synthesis reaction kettle and p...

Embodiment 3

[0044] Step 1. Polish the TiNb alloy sheet with a size of 30mm×10mm×2mm sequentially with 240#, 600# and 1400# water sandpaper, then place the polished TiNb alloy sheet in acetone for ultrasonic degreasing, and then use deionized After washing with water, dry naturally; the mass percentage of Nb in the TiNb alloy sheet is 50%, and the balance is Ti and other unavoidable impurities;

[0045] Step 2, dissolving silver nitrate and calcium nitrate in hydrogen peroxide solution to obtain a mixed solution; the hydrogen peroxide solution is commercial hydrogen peroxide with a mass percentage of 30%; the concentration of silver nitrate in the mixed solution is 20mmol / L, calcium nitrate The concentration is 15mmol / L;

[0046] Step 3, adding the mixed solution described in step 2 into the hydrothermal synthesis reaction kettle, then putting the air-dried TiNb alloy sheet in the step 1 into the hydrothermal synthesis reaction kettle, sealing the hydrothermal synthesis reaction kettle and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com