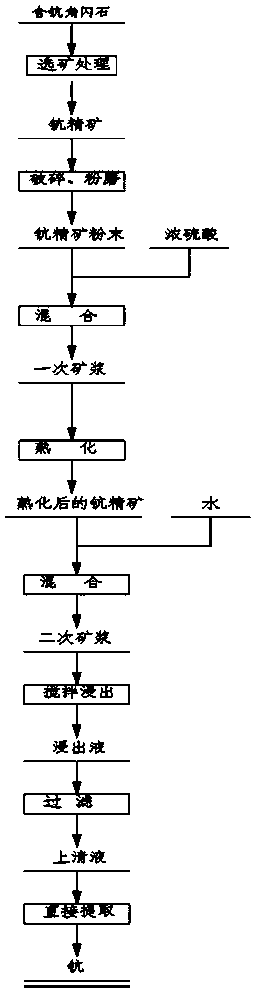

Method for extracting scandium from Sc-containing amphibole concentrates

A technology of hornblende and concentrate, applied in the field of scandium extraction, can solve the problems of high leaching rate, low leaching rate, and increased extraction cost, and achieve the effect of high extraction rate, high decomposition rate and clean method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Sc 2 o 3 The content is 90~96g / t. The scandium concentrate is crushed and ground into powder, and the scandium concentrate is ground until the content of -0.074mm reaches more than 80%, and the scandium concentrate powder is obtained. Mix the scandium concentrate powder with concentrated sulfuric acid, the mass ratio of the scandium concentrate powder to the concentrated sulfuric acid is 1:0.6 to obtain a primary pulp; the primary pulp is matured, the temperature of the curing system is 60°C, and the mature The time is 24 hours, and the aged scandium concentrate is obtained. Mixing the matured scandium concentrate with water, the ratio of the mass of the matured scandium concentrate to the volume of water is 1:50 to obtain a secondary pulp; stirring the secondary pulp at a certain temperature For leaching, the stirring speed is 170 rpm, the temperature of the leaching system is 30° C., and the leaching time is 7 days to obtain a leaching solution. After testing, com...

Embodiment 2

[0033] Sc 2 o 3 The content is 90~96g / t. The scandium concentrate is crushed and ground into powder, and the scandium concentrate is ground until the content of -0.074mm reaches more than 80%, and the scandium concentrate powder is obtained. Mix the scandium concentrate powder with concentrated sulfuric acid, the volume ratio of the scandium concentrate powder to the concentrated sulfuric acid is 1:0.9, and obtain a primary pulp; the primary pulp is matured, the temperature of the curing system is 200°C, and the mature The time is 9 hours, and the aged scandium concentrate is obtained. Mixing the matured scandium concentrate with water, the ratio of the mass of the matured scandium concentrate to the volume of water is 1:20 to obtain a secondary pulp; stirring the secondary pulp at a certain temperature For leaching, the stirring speed is 230 rpm, the temperature of the leaching system is 75° C., and the leaching time is 3 days to obtain a leaching solution. After testing,...

Embodiment 3

[0035] Sc 2 o 3The content is 90~96g / t. The scandium concentrate is crushed and ground into powder, and the scandium concentrate is ground until the content of -0.074mm reaches more than 80%, and the scandium concentrate powder is obtained. Mix the scandium concentrate powder with concentrated sulfuric acid, the volume ratio of the scandium concentrate powder to the concentrated sulfuric acid is 1:0.9, and obtain a primary pulp; the primary pulp is matured, the temperature of the curing system is 200°C, and the mature The time is 12 hours, and the aged scandium concentrate is obtained. Mixing the matured scandium concentrate with water, the ratio of the mass of the matured scandium concentrate to the volume of water is 1:50 to obtain a secondary pulp; stirring the secondary pulp at a certain temperature For leaching, the rotational speed of stirring is 170 rpm, the temperature of the leaching system is 45° C., and the leaching time is 7 days to obtain a leaching solution. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com