Manufacturing method for high-purity iron-chromium-aluminum alloy powder

An iron-chromium-aluminum alloy and manufacturing method technology, applied in metal processing equipment, transportation and packaging, additive processing, etc., can solve problems such as creep deformation, poor plasticity and toughness, and brittle fracture of heating elements, etc., and achieve reduction Effects of inclusions, uniform resistivity, and prevention of powder oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

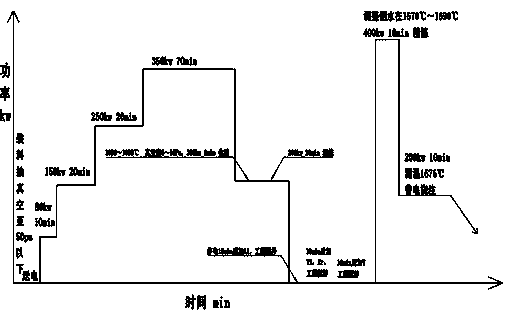

[0032] This embodiment provides a method for manufacturing high-purity iron-chromium-aluminum alloy powder, including the following steps:

[0033] S1: Raw material preparation: Alloy ingredients are composed of the following components by weight percentage: Ti: 0.11%, Al: 5.9%, Cr: 22%, Co: 0.015%, Zr: 0.16%, Y: 0.5%, Fe is the balance , The total weight of ingredients is 640kg. Prepare fused magnesia sand crucible or fused magnesia spinel crucible; (the furnace before smelting is a nickel-based superalloy, considering the residual components of the crucible, so no nickel strips are added) 150*1100 precision seamless steel pipes are used as 4 mold pipes , 1 chute, and 3 diverter plates; metal raw materials must be clean, dry, and rust-free. New crucibles or crucibles must be carefully baked after repairing, otherwise they cannot be used.

[0034] : Preheat the steel ingot assembly mold to 530°C, keep it warm for 3 hours, hang it in the furnace while it is hot, align it with ...

Embodiment approach 2

[0059] This embodiment provides a method for manufacturing high-purity iron-chromium-aluminum alloy powder that is exactly the same as Embodiment 1, which will not be described in detail here. The only difference is that the alloy ingredients in this embodiment are composed of the following components in weight percentage: Ti: 0.11%, Al: 5.9%, Cr: 22%, Co: 0.015%, Zr: 0.16%, Y: 0.5%, Fe is the balance, and the total weight of ingredients is 420kg.

Embodiment approach 3

[0061] This embodiment provides a method for manufacturing high-purity iron-chromium-aluminum alloy powder that is exactly the same as Embodiment 1, which will not be described in detail here. The only difference is that the alloy ingredients in this embodiment are composed of the following components in weight percentage: Ti: 0.07%, Al: 5.7%, Cr: 22%, Co: 0.010%, Zr: 0.1%, Y: 0.5%, Fe is the balance, and the total weight of ingredients is 615kg.

[0062] The following table 1 is the alloy composition after smelting and the atomized powder alloy composition table (unit %)

[0063]

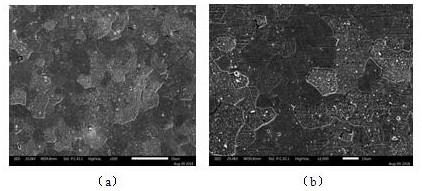

[0064] Table 2 below shows the particle size distribution, specific surface area, and oxygen content of the Fe-Cr-Al alloy powder prepared in Embodiment 1.

[0065]

[0066] It can be seen from Table 2 that the powder has low oxygen content and good surface activity, which can provide high-quality raw materials for subsequent powder molding processing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com