Lithium-sulfur battery diaphragm and preparation method thereof

A lithium-sulfur battery and diaphragm technology, which is applied in the field of lithium-sulfur battery diaphragm preparation, can solve the problems of lithium-sulfur battery actual capacity reduction, attenuation, hindering electrons, ion transport electrochemical reactions, etc., and achieve good thermal stability and electrolyte Wettability, low cost, and the effect of suppressing the shuttling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

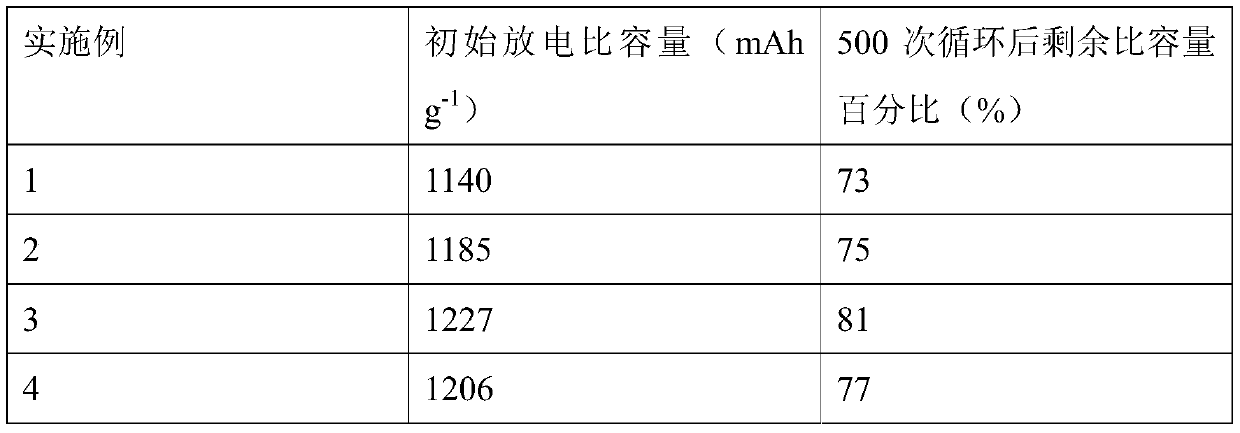

Embodiment 1

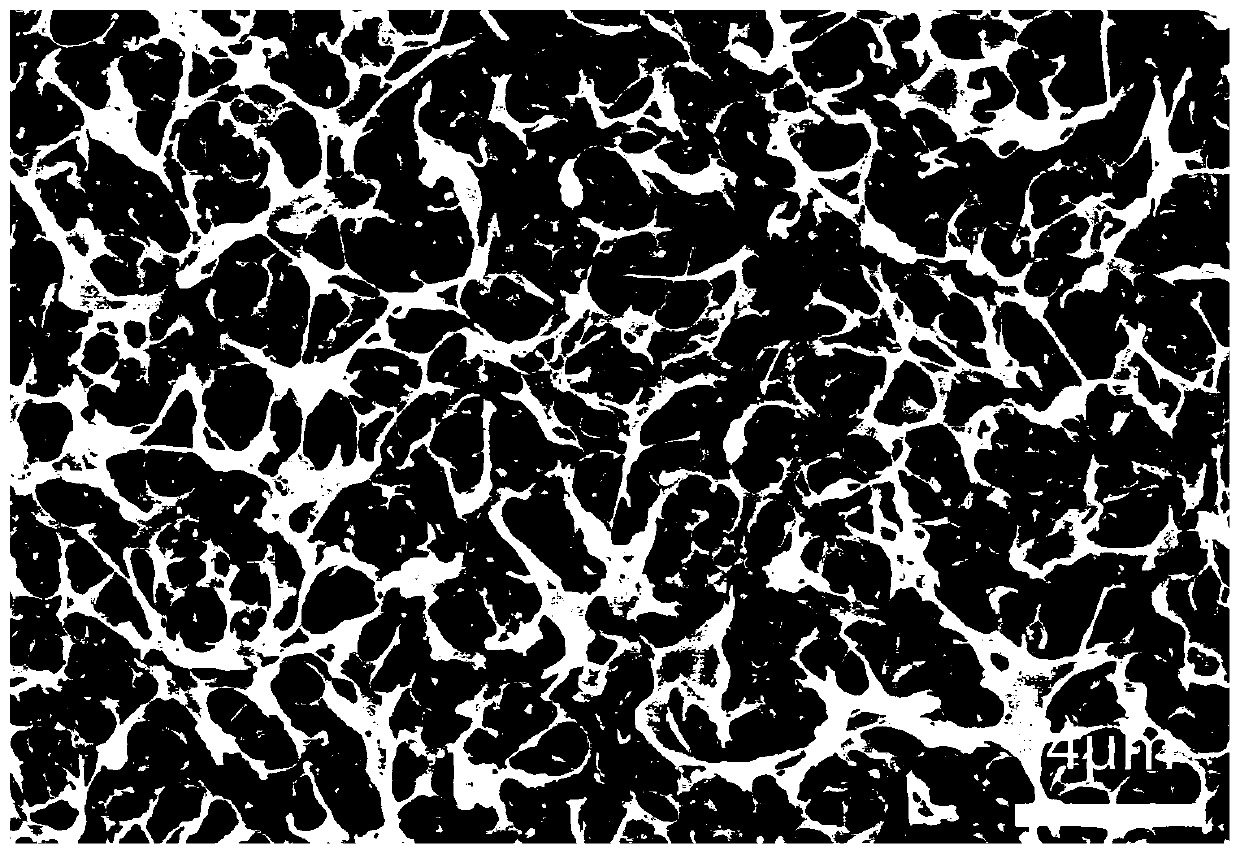

[0029] A lithium-sulfur battery diaphragm is a porous film prepared by using a non-solvent induced phase separation method to prepare a polyvinyl alcohol (PVA) / carboxymethyl cellulose sodium (CMC-Na) blending film casting solution.

[0030] The preparation method of the above-mentioned lithium-sulfur battery separator is:

[0031] The first step: PVA (Sigma-Aldrich, Mw 85,000-124,000, 99+% hydrolyzed) and CMC-Na (Dacellul CMC2200) were dissolved in deionized water to prepare 10wt% and 8wt% polymer aqueous solutions respectively;

[0032] The second step: the PVA aqueous solution and the CMC-Na aqueous solution are mixed into a homogeneous blended film casting solution based on the CMC-Na accounting for 15% of the total polymer mass fraction, and the total polymer mass fraction in the film casting solution is 8%. After standing for defoaming, spread the casting liquid evenly on the glass plate with a spatula;

[0033] The third step: Place the glass plate coated with the casting liquid...

Embodiment 2

[0035] A lithium-sulfur battery diaphragm is a porous film prepared by using a non-solvent induced phase separation method to prepare a polyvinyl alcohol (PVA) / carboxymethyl cellulose sodium (CMC-Na) blending film casting solution.

[0036] The preparation method of the above-mentioned lithium-sulfur battery separator is:

[0037] The first step: PVA (Sigma-Aldrich, Mw 85,000-124,000, 99+% hydrolyzed) and CMC-Na (Dacellul CMC2200) were dissolved in deionized water to prepare 10wt% and 8wt% polymer aqueous solutions respectively;

[0038] The second step: the PVA aqueous solution and the CMC-Na aqueous solution are mixed into a homogeneous blended film casting solution based on the CMC-Na accounting for 20% of the total polymer mass fraction, and the total polymer mass fraction in the film casting solution is 8%. After standing for defoaming, spread the casting liquid evenly on the glass plate with a spatula;

[0039] The third step: the glass plate coated with the casting solution is ...

Embodiment 3

[0041] A lithium-sulfur battery diaphragm is a porous film prepared by using a non-solvent induced phase separation method to prepare a polyvinyl alcohol (PVA) / carboxymethyl cellulose sodium (CMC-Na) blending film casting solution.

[0042] The preparation method of the above-mentioned lithium-sulfur battery separator is:

[0043] Step 1: Dissolve PVA (Sigma-Aldrich, Mw 85,000-124,000, 99+% hydrolyzed) and CMC-Na (Dacellul CMC2200) in deionized water to prepare 10wt% and 8wt% polymer aqueous solutions respectively. ;

[0044] The second step: the PVA aqueous solution and the CMC-Na aqueous solution are mixed into a homogeneous blended film casting solution based on CMC-Na accounting for 25% of the total polymer mass fraction, and the total polymer mass fraction in the film casting solution is 8%. After standing for defoaming, spread the casting liquid evenly on the glass plate with a spatula;

[0045] The third step: Place the glass plate coated with the casting solution in an absolu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com