Organic single crystal spin valve and preparation method and application thereof

A spin valve, single crystal technology, applied in the fields of magnetic field controlled resistors, electromagnetic device manufacturing/processing, material selection, etc., can solve problems such as low yield rate, achieve high yield rate, strong universality, The effect of increasing the carrier spin diffusion length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1、2

[0047] Preparation example 1, preparation of 2,6 diphenylanthracene (2,6-DPA) single crystal micron material

[0048] 1) Silicon wafer cleaning:

[0049] with SiO 2 Before use, the silicon wafer of the oxide layer should be cleaned with hydrogen peroxide:concentrated sulfuric acid (heated in an electric furnace, boiled) at a ratio of about 1:2, then ultrasonicated with deionized water, absolute ethanol and acetone for about 10 minutes, and finally used Dry quickly with nitrogen and place in an oxygen plasma generator for about 15 seconds.

[0050] 2) Silicon wafer surface modification

[0051] Place the cleaned silicon wafer in a petri dish in a vacuum drying oven, vacuumize and heat to 80°C for about 1 hour, keep the vacuum down to room temperature, and drop a small amount of n-octadecane near the silicon wafer in the petri dish Trichlorosilane (OTS), evacuated and heated to 120° C. for about 2 hours, and kept under vacuum to allow it to cool to room temperature. The modi...

Embodiment 1

[0056] 1. Preparation of lanthanum strontium manganese oxide (LSMO) ferromagnetic bottom electrode

[0057] 1.1) Patterned metal mask

[0058] A metal mask with a reasonable size can be customized according to the needs, and its patterned size determines the size of the lanthanum strontium manganese oxide (LSMO) ferromagnetic bottom electrode. The width here is preferably 500 μm.

[0059] 1.2) Preparation of lanthanum strontium manganese oxide (LSMO) ferromagnetic bottom electrode

[0060] Fix the patterned metal mask and the strontium titanate (STO) substrate, and put them into the DC facing target sputtering chamber. During the growth process, the substrate temperature is kept at 700-800°C, and the pressure in the chamber is about 0.5-1.0Pa, the carrier gas is the ratio Ar:O 2 = 5:3 mixture. After the epitaxial growth of 100nm-thick lanthanum strontium manganese oxide (LSMO) ferromagnetic electrode was completed, the pure O in situ at 3KPa 2 In the atmosphere, keep anne...

Embodiment 2

[0069] Embodiment 2 device performance test

[0070] The 2,6-diphenylanthracene single crystal spin valve prepared in Example 1 was tested by Quantum Designed physical property measurement system (PPMS). Under an external 0.5T magnetic field, the magnetoresistance change is about 10% at 2K.

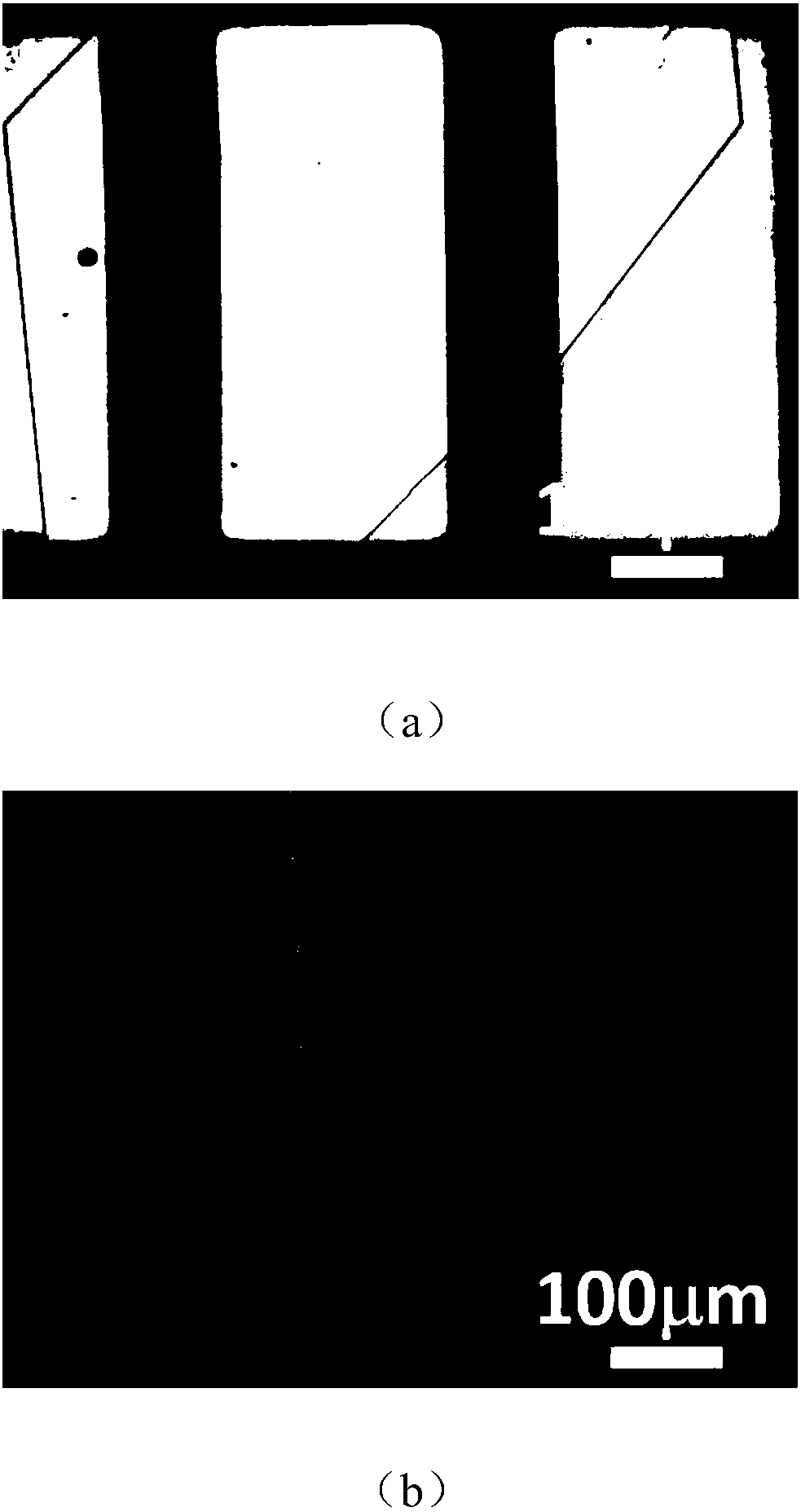

[0071] Figure 4 is the magnetoresistance curve (MR) of a 2,6 diphenylanthracene single crystal spin valve, given by Figure 4 It can be seen from the symmetrical MR curve that the spin single crystal spin valve device is successfully prepared, and the magnetoresistance change is about 10% at 2K.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com