Modified nano-hydroxyapatite supramolecular composite hydrogel and preparation method thereof

A nano-hydroxyapatite and composite hydrogel technology is applied in the field of biomedical composite materials, which can solve the problems of limited application and difficult composite, and achieve the effects of improving mechanical properties, easy preparation and excellent biocompatibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

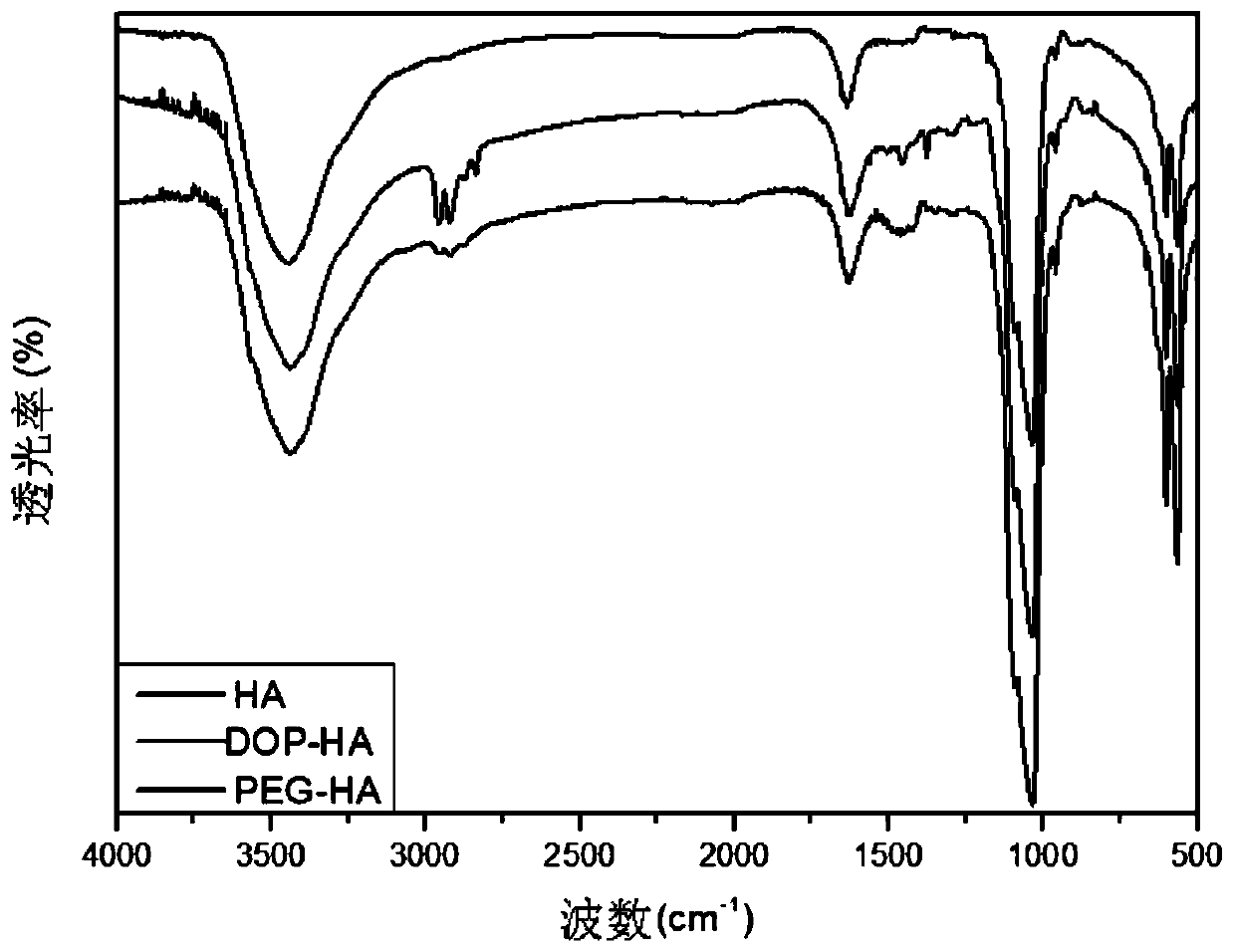

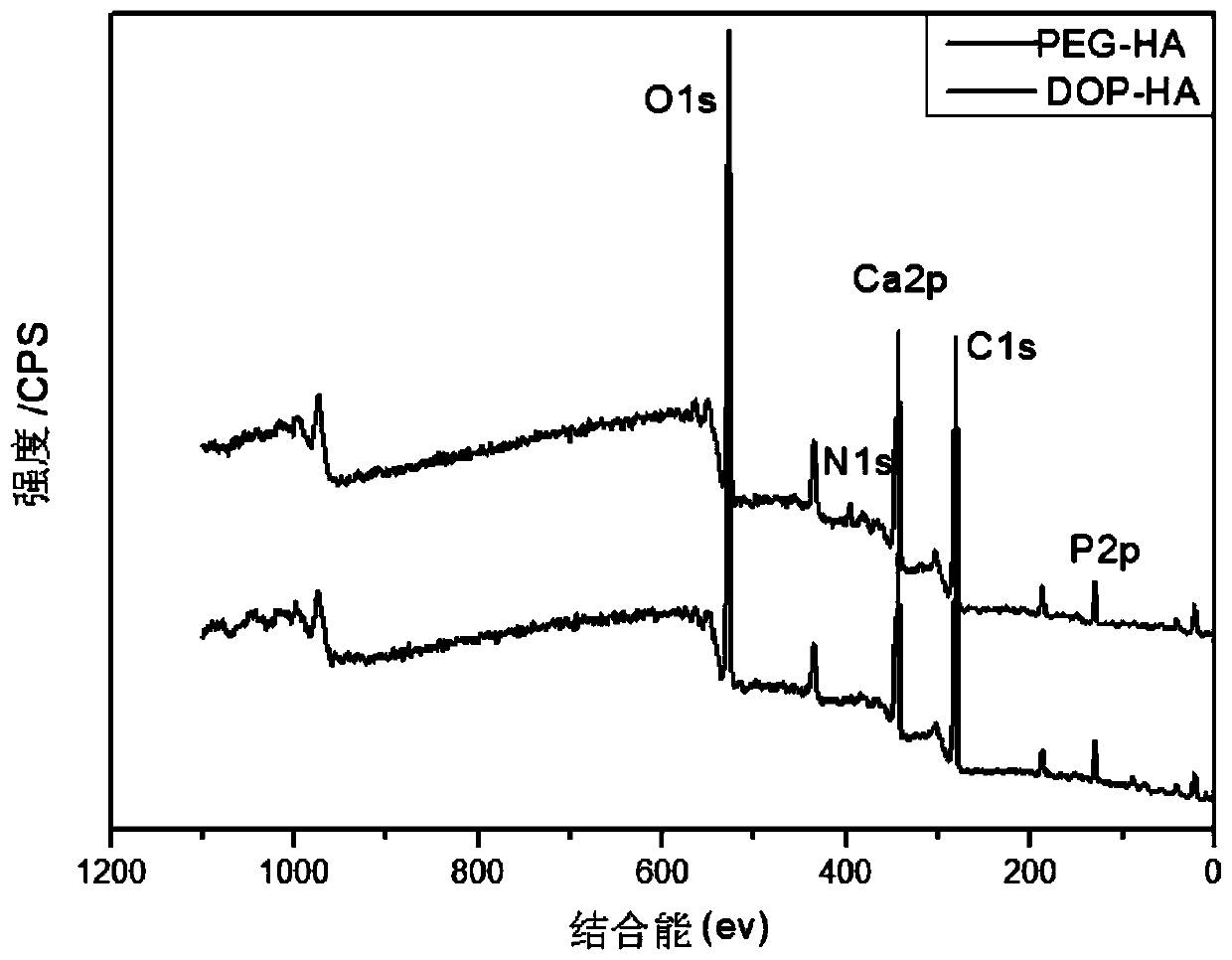

[0030] (1) Dissolve 121.1 g tris (1 mmol) in 10 mL deionized water, then dilute it 10 times to make a 10 mM buffer solution, add 1 mM dilute hydrochloric acid to adjust the pH of the buffer solution to 8.4. 120mg dopamine (0.78mmol) was dissolved in 30mL buffer solution, then 200mg nano-hydroxyapatite (0.2mmol) was added in dopamine buffer solution, stirred and reacted for 16 hours, then the product obtained after the reaction was centrifuged, washed, After drying, the dried product was washed with ethanol, centrifuged and then vacuum-dried to obtain hydroxyapatite (DOP-nHA) with dopamine on the surface.

[0031] (2) 200 mg (0.04 mmol) of methoxypolyethylene glycol amine (PEG-NH) with a molecular weight of 5000 Da 2 ) was dissolved in 1mL deionized water, then 40mg (0.04mmol) DOP-nHA was added to the solution, and stirred at room temperature for 16 hours. After the reaction, the product was centrifuged, washed, and vacuum-dried to obtain PEG-modified nano-hydroxyphosphorus Li...

Embodiment 2

[0034] (1) Dissolve 121.1 g tris (1 mmol) in 10 mL deionized water, then dilute it 10 times to make a 10 mM buffer solution, add 1 mM dilute hydrochloric acid to adjust the pH of the buffer solution to 8.4. 180mg dopamine (1.18mmol) was dissolved in 30mL buffer solution, then 400mg nano-hydroxyapatite (0.4mmol) was added in dopamine buffer solution, stirred and reacted for 24 hours, then the product obtained after the reaction was centrifuged, washed, After drying, the dried product was washed with ethanol, centrifuged and then vacuum-dried to obtain hydroxyapatite (DOP-nHA) with dopamine on the surface.

[0035] (2) 300 mg (0.06 mmol) of methoxypolyethylene glycol amine (PEG-NH) with a molecular weight of 5000 Da 2 ) was dissolved in 1mL deionized water, then 30mg (0.03mmol) DOP-nHA was added to the solution, and stirred at room temperature for 24 hours. After the reaction, the product was centrifuged, washed, and vacuum-dried to obtain PEG-modified nano-hydroxyphosphorus Li...

Embodiment 3

[0038](1) Dissolve 121.1g tris (0.001mol) in 10mL deionized water, then dilute it 10 times to make a 10mM buffer solution, add 1mM dilute hydrochloric acid to adjust the pH of the buffer solution to 8.4. 150mg dopamine (0.98mmol) was dissolved in 30mL buffer solution, then 300mg nano-hydroxyapatite (0.3mmol) was added in the dopamine buffer solution, stirred and reacted for 36 hours, and the product obtained after the reaction was centrifuged, washed, After drying, the dried product was washed with ethanol, centrifuged and then vacuum-dried to obtain hydroxyapatite (DOP-nHA) with dopamine on the surface.

[0039] (2) 300 mg (0.06 mmol) of methoxypolyethylene glycol amine (PEG-NH) with a molecular weight of 5000 Da 2 ) was dissolved in 1mL deionized water, then 20mg (0.02mmol) DOP-nHA was added to the solution, and stirred at room temperature for 36 hours. After the reaction, the product was centrifuged, washed, and vacuum-dried to obtain PEG-modified nano-hydroxyphosphorus Li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com