A kind of sulfur particle separation system and method

A technology of sulfur particles and separation system, applied in separation methods, dispersed particle separation, filtration separation, etc., can solve the problems of high investment cost, unfavorable process control, complicated operation process, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

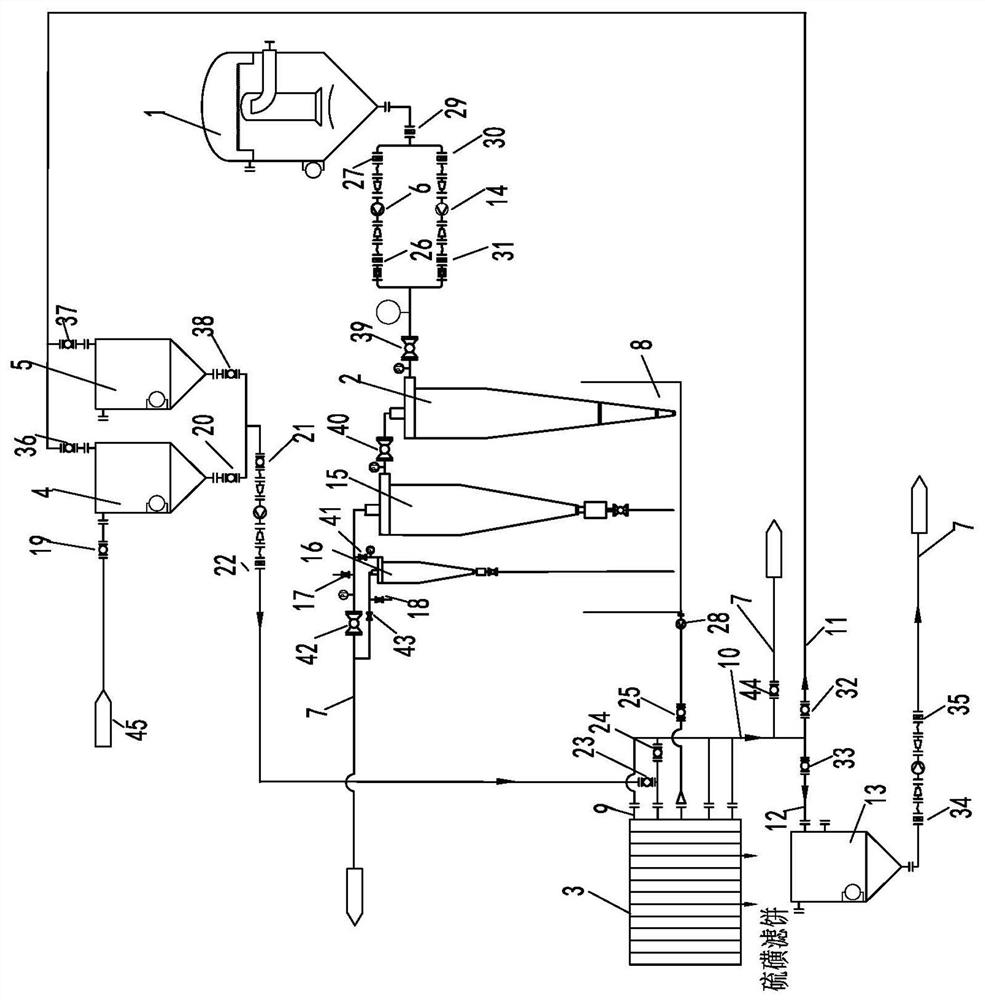

[0033] refer to figure 1 , a sulfur particle separation system, belonging to the technical field of waste gas purification treatment in the field of viscose fiber production, comprising a sulfur slurry settling tank 1, a desander I2, a plate and frame filter 3, a desalinated water tank 4 and a flushing tank 5, said The sulfur slurry settling tank 1 and the desander I2 are connected by a pipeline, and the pipeline is provided with a sulfur slurry pump 6, and the inlet and outlet ends of the sulfur slurry pump 6 are respectively provided with No. 9 valve 27 and No. 8 valve 26; No. 10 valve 29 is provided at the outlet of sulfur slurry settling tank 1. The outlet at the upper end of the desander I2 is connected to the desulfurizer recovery pipeline 7. The outlet at the upper end of the desander I2 is provided with a No. 21 valve 40. The outlet of the lower end of the sander I2 is connected with a tailings tank 8; the tailings tank 8 is connected to the plate and frame filter 3 th...

Embodiment 2

[0051] Compared with Example 1, the present embodiment differs in that in step E, when the liquid level is full, close the No. 1 valve 19 and No. 2 valve 20, open the No. 19 valve 38, and keep circulating for 30 minutes; in step F, After the flushing tank 5 is full, close No. 1 valve 19 and No. 2 valve 20, open No. 19 valve 38, and keep circulating for 30 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com