Patterning microarray flowing tank, manufacturing method, detection method and application of flowing tank

A flow cell and patterning technology, applied in biochemical equipment and methods, microbial measurement/inspection, etc., can solve problems such as high cost, low throughput of sequencer, and no practical value of sequencing information

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

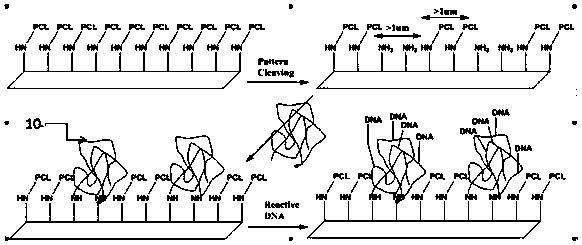

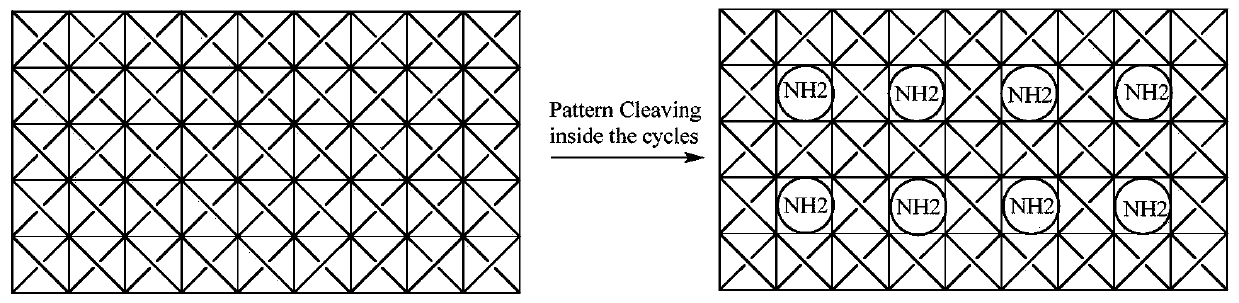

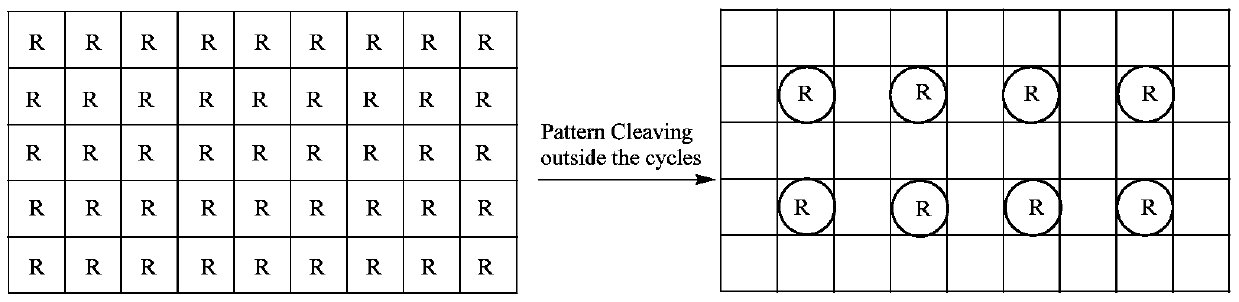

Method used

Image

Examples

Embodiment 1

[0105] Surface activation of glass slides.

[0106] Take a 25 mm x 75 mm x 0.5 mm glass slide, sonicate it in 0.5 wt% SDS aqueous solution for 20 minutes, and then wash it thoroughly with deionized water. Then ultrasonic treatment in 29% ammonia water, 30% hydrogen peroxide (H2O2), deionized water, 1:1:5 (volume ratio) solution for 20 minutes and then thoroughly cleaned with deionized water. Then ultrasonically treat for 20 minutes in a solution of 38% HCl and 30% hydrogen peroxide (H2O2) and deionized water with a volume ratio of 1:1:6, and then rinse thoroughly with deionized water. The treated slides were placed in deionized water and kept tightly covered. When in use, they were taken out and dried with argon gas, and then baked at 110°C for 5 minutes. The water contact angle of this pre-treated slide is less than 10 degrees. The prepared substrate can be used to form a layer of NH2 groups, and then immobilize a layer of photodegradable chains on the surface of the substr...

Embodiment 2

[0108] 3-Aminopropyltrimethoxysilane was used to form NH2 groups on the slide surface.

[0109] Add 30 milliliters of absolute ethanol, 500 microliters of 3-aminopropyltrimethoxysilane and 20 microliters of triethylamine into a polypropylene chip tube with a screw cap, and put 5 slides pretreated in Example 1 , shake for 3 hours. Take out the glass slide, wash it with a sufficient amount of 95% ethanol, blow it dry with argon, and place it in an oven at 110°C for annealing treatment for 5 minutes. Prepared slides are immediately used in the next step to covalently immobilize a layer of photolyzable linkages on the substrate surface.

Embodiment 3

[0111] 1-(bromomethyl)-2-nitrobenzene is covalently immobilized on the surface of the glass slide (Example 2) with NH2, so that there is no reactive group on the surface of the glass slide.

[0112] Weigh 2.16 mg of 1-(bromomethyl)-2-nitrobenzene and add it to 2 ml of absolute ethanol (FW214.96, 0.01 mmol, 5 mM), add 2 microliters of DIPEA (diisopropylethylamine, FW129. 24, ρ=0.782, 0.012mmol, 6mM) and added dropwise onto the surface of the glass slide (Example 2) with NH2 groups, left to stand for 3 hours, rinsed with ethanol, and dried with argon. The covalent immobilization reaction process of embodiment 3 is as follows:

[0113]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com