Preparing method and application of near-infrared response carbon dots

A near-infrared and carbon dot technology, applied in chemical instruments and methods, medical preparations containing active ingredients, nano-carbon, etc., can solve problems such as high cost, limited application of carbon quantum dots, and long preparation cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

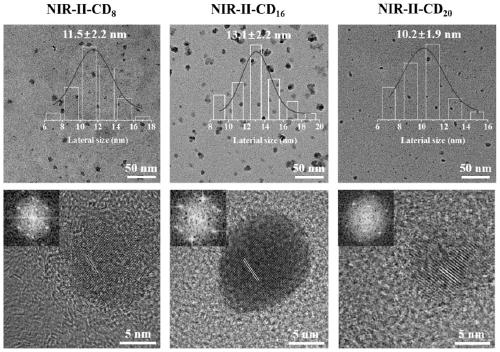

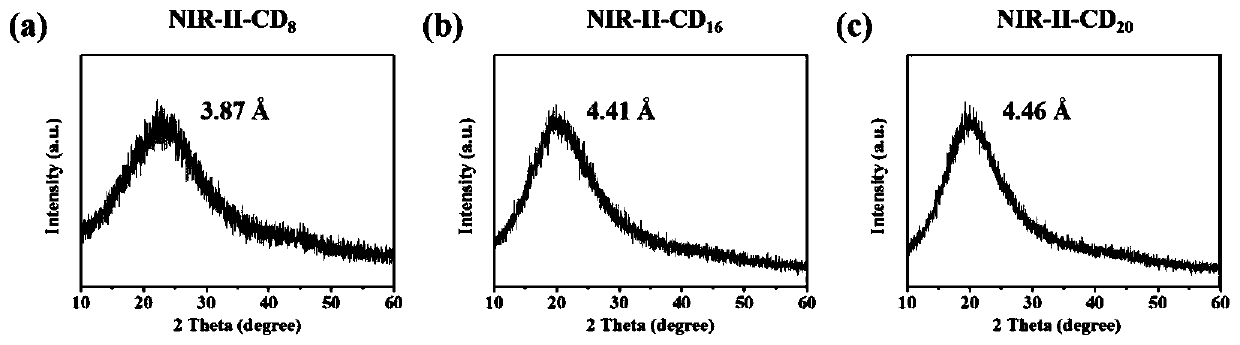

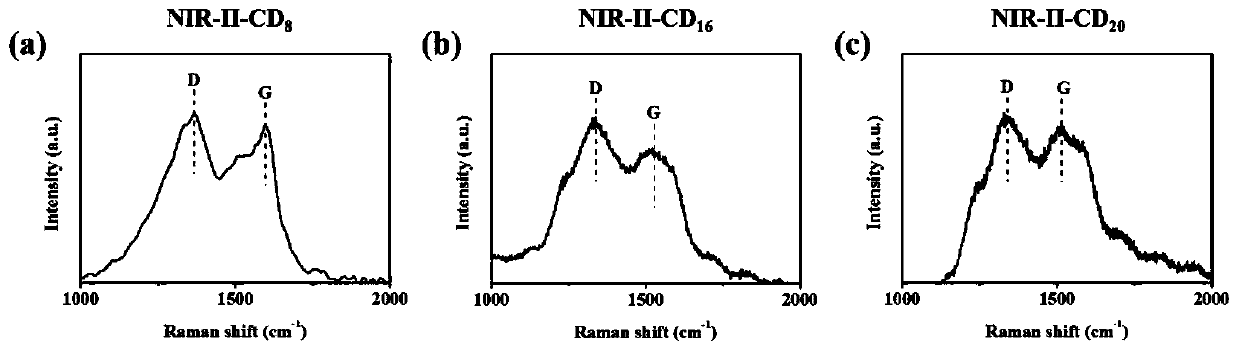

[0052] This embodiment is a method for preparing carbon dots responding to the second near-infrared region, which includes the following steps:

[0053] 1) Add 2g of pyrene to 160mL of concentrated nitric acid, condense and reflux at 80°C for 24 hours, dilute the resulting mixture with deionized water to wash the acid in the solution, and finally use a 220nm filter to remove large particles, and then dry to obtain trinitrate Base pyrene powder.

[0054] 2) Take 0.1 g of trinitropyrene obtained in the first step, dissolve 0.1 g of polyethyleneimine in 10 mL of deionized water and stir and mix with trinitropyrene, put it into a microwave reactor, and react at 150 ° C for 120 min.

[0055] 3) the black liquid obtained in step 2 is passed through a 220nm filter membrane, the filtrate is forwarded to the dichloromethane phase, and the neutral alumina chromatography column is used to filter and remove the small molecular organic matter for reaction, and then dry to obtain a black po...

Embodiment 2

[0057] This embodiment is a method for preparing carbon dots responding to the second near-infrared region, which includes the following steps:

[0058] 1) Add 3g of pyrene to 240mL of concentrated nitric acid, condense and reflux at 80°C for 30h, dilute the resulting mixture with deionized water to wash the acid in the solution, and finally use a 220nm filter to remove large particles, and then dry to obtain trinitrate Base pyrene powder.

[0059] 2) Take 0.1 g of trinitropyrene obtained in the first step, dissolve 2.5 g of polyethyleneimine in 10 mL of deionized water and stir and mix with trinitropyrene, put it into a microwave reactor, and react at 170 ° C for 80 min.

[0060] 3) the black liquid obtained in step 2 is passed through a 220nm filter membrane, the filtrate is forwarded to the dichloromethane phase, and the neutral alumina chromatography column is used to filter and remove the small molecular organic matter for reaction, and then dry to obtain a black powder. ...

Embodiment 3

[0062] This embodiment is a method for preparing carbon dots responding to the second near-infrared region, which includes the following steps:

[0063] 1) Add 4g of pyrene to 320mL of concentrated nitric acid, condense and reflux at 80°C for 48h, dilute the resulting mixture with deionized water to wash the acid in the solution, and finally use a 220nm filter to remove large particles, and then dry to obtain trinitrate Base pyrene powder.

[0064] 2) Take 0.1 g of trinitropyrene obtained in the first step, dissolve 0.8 g of polyethyleneimine in 10 mL of deionized water and stir and mix with trinitropyrene, put it into a microwave reactor, and react at 180 ° C for 2 minutes.

[0065] 3) Pass the black liquid obtained in step 2 through a 220nm filter membrane, transfer the filtrate to the dichloromethane phase, filter with a neutral alumina chromatography column to remove the small molecule organic matter for the reaction, and then dry to obtain a black powder, namely NIR -II-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com