Molded glass fiber-reinforced plastic cable bridge

A technology of cable tray and FRP, which is applied in the fields of electrical components, chemical industry, climate sustainability, etc. It can solve problems such as poor corrosion resistance, loss of alloy elements, deformation of aluminum alloy, etc., and achieve improved corrosion resistance and good hydrophobicity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

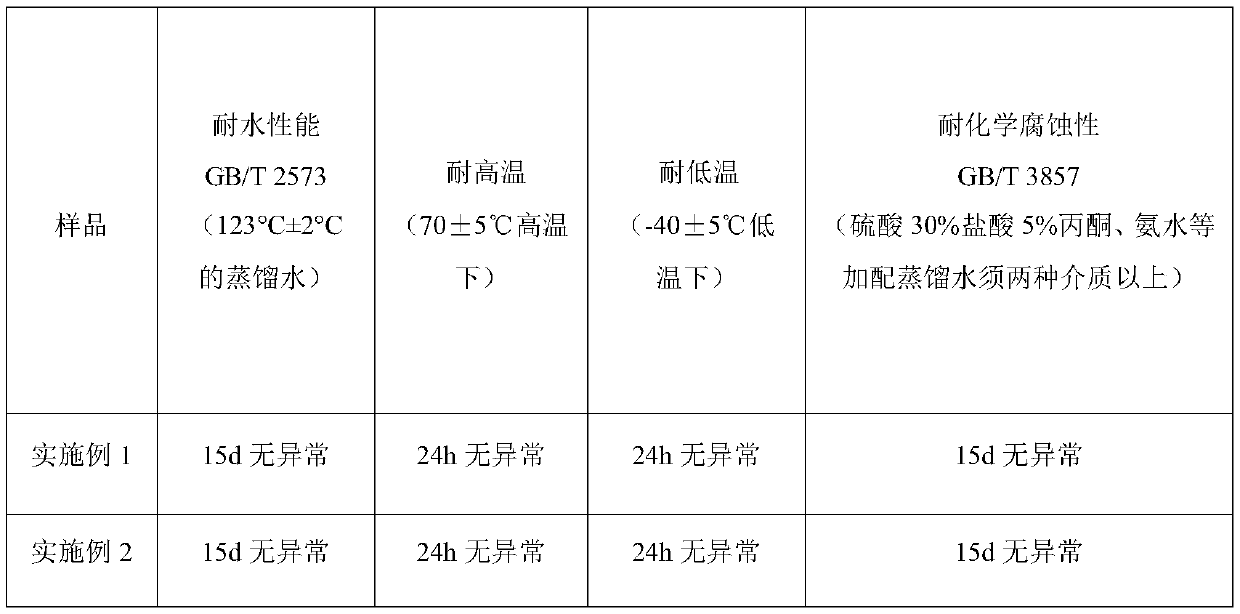

Examples

Embodiment 1

[0020] A molded fiberglass cable tray, comprising the following components in parts by weight: 60 parts of ABS resin, 40 parts of modified glass fiber composite liquid, 6 parts of rectorite, 4 parts of magnesium oxide, 5 parts of ethylenediamine, and 11 parts of magnesium hydroxide 7 parts, 7 parts of cobalt isooctanoate and 1 part of graphite;

[0021] The processing technology of the above-mentioned formed FRP cable bridge is as follows:

[0022] A. Preparation of modified glass fiber composite liquid

[0023] 1) Preparation of modifier: Add 55 parts of 3-ethylene-7-oxydicyclohexane and 55 parts of vinyldimethoxysilane into the reactor; then disperse 2 parts of chloroplatinic acid in 100 parts of isopropyl Alcohol, put it into the reaction kettle, and react at 70°C for 2 hours to obtain the modifier;

[0024] 2) Hydrolysis of the modifier: at room temperature, mix according to the volume ratio V (modifier): V (water): V (methanol) = 1:1:3, and hydrolyze under the condition...

Embodiment 2

[0028] A molded fiberglass cable tray, comprising the following components by weight: 70 parts of ABS resin, 40 parts of modified glass fiber composite liquid, 4 parts of rectorite, 6 parts of magnesium oxide, 5 parts of ethylenediamine, and 8 parts of magnesium hydroxide 7 parts, 7 parts of cobalt isooctanoate and 3 parts of graphite;

[0029] The processing technology of the above-mentioned formed FRP cable bridge is as follows:

[0030] A. Preparation of modified glass fiber composite liquid

[0031] 1) Preparation of modifier: add 40 parts of 3-ethylene-7-oxydicyclohexane and 65 parts of vinyldimethoxysilane in the reactor; then disperse 2.5 parts of chloroplatinic acid in 120 parts of isopropyl Alcohol, put it into the reaction kettle, and react at 90°C for 2.5h to obtain the modifier;

[0032] 2) Modifier hydrolysis: mix according to the volume ratio V (modifier): V (water): V (methanol) = 1:1:3.5 at room temperature, and hydrolyze under the condition of pH=5 to obtain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com