Waterproof and moisture-permeable degradable fiber-based nonwoven composite material and preparation method thereof

A technology of composite materials and degradable fibers, which is applied in non-woven fabrics, textiles and papermaking, and can solve problems such as difficult to ink, easy to scatter ink, and difficult to pack

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

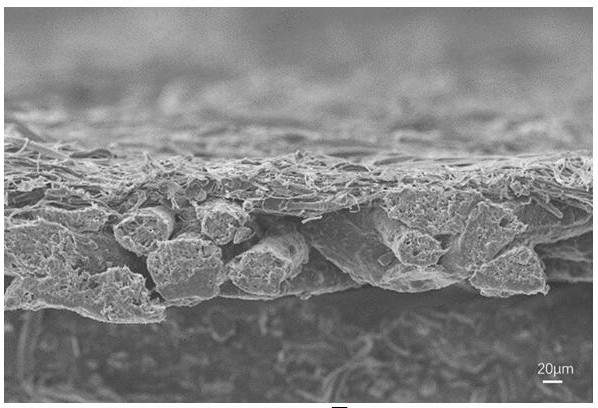

[0022] The waterproof and moisture-permeable degradable fiber-based nonwoven composite material of this embodiment includes a coarse denier limestone filament layer and a polylactic acid fiber layer of ultrafine fibers prepared by a melt blown process, and the polylactic acid fiber layer of ultrafine fibers is pulverized coal Grey, polyethylene glycol modified polylactic acid and metallocene modified polypropylene meltblown microfiber material with an areal density of 222g / m 2 , the thickness is 0.28mm, the coarse denier limestone filament layer is a filament-based fiber material made of limestone and thermoplastic polymer through polymer melt extrusion molding process, and the fiber fineness is 1.5~6.6D.

[0023] The raw materials of the superfine fiber polylactic acid fiber layer include fly ash, polyethylene glycol, polylactic acid and metallocene-modified polypropylene, wherein the mass fraction of fly ash is 76%, and the polylactic acid accounts for The mass fraction is 1...

Embodiment 2

[0029] The raw material of the superfine fiber polylactic acid fiber layer of the present embodiment comprises fly ash, polyethylene glycol, polylactic acid and the polypropylene modified by metallocene, wherein the mass fraction that fly ash accounts for is 71%, polylactic acid accounts for The mass fraction of polyethylene glycol is 18%, the mass fraction of metallocene-modified polypropylene is 7%, and the mass fraction of polyethylene glycol is 4%.

[0030] The preparation method of the waterproof and moisture-permeable degradable fiber-based nonwoven composite material of this embodiment, the steps are as follows:

[0031] (1) Preparation of coarse denier limestone filament layer: flatten the coarse denier limestone filament layer;

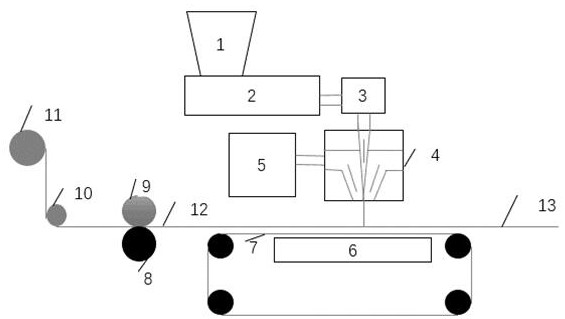

[0032](2) Preparation and online compounding of ultrafine fiber polylactic acid fiber layer: the coarse denier limestone filament layer in step (1) is placed under the melt-blown spinning die head, and the temperature of the spinning die head...

Embodiment 3

[0035] The raw material of the superfine fiber polylactic acid fiber layer of the present embodiment comprises fly ash, polyethylene glycol, polylactic acid and polypropylene modified by metallocene, wherein the mass fraction of fly ash accounts for 67%, polylactic acid accounts for The mass fraction of polyethylene glycol is 21%, the mass fraction of metallocene-modified polypropylene is 8%, and the mass fraction of polyethylene glycol is 4%.

[0036] The preparation method of the waterproof and moisture-permeable degradable fiber-based nonwoven composite material of this embodiment, the steps are as follows:

[0037] (1) Preparation of coarse denier limestone filament layer: flatten the coarse denier limestone filament layer;

[0038] (2) Preparation and online compounding of ultrafine fiber polylactic acid fiber layer: the coarse denier limestone filament layer in step (1) is placed under the melt-blown spinning die head, and the temperature of the spinning die head is 235...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com