Quartz glass fiber-containing prepreg quartz glass fiber-containing film and quartz glass fiber-containing substrate

A technology of quartz glass fiber and prepreg, which is applied in the direction of glass/slag layered products, layered products, chemical instruments and methods, etc., and can solve problems such as the inability to adhere to the plating layer, the reduction of dielectric properties, and poor conduction. , to achieve excellent surface uniformity, high tensile stiffness characteristics, and excellent plating properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~2、 comparative example 1~7

[0131] (Preparation of quartz glass fiber)

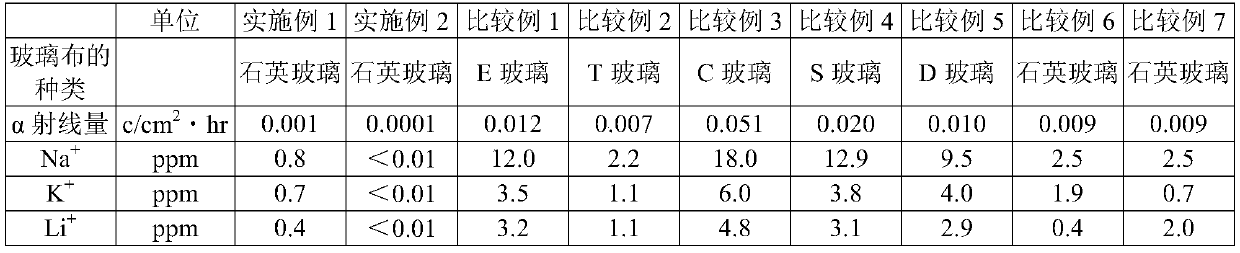

[0132] Glass cloths having a thickness of 0.1 mm used in Examples 1 to 2 and Comparative Examples 1 to 7 were prepared using glasses shown in Table 1 below. Table 1 also describes the types and doses of α-rays, and the ion components of Na, Li, and K. In addition, the quartz glass cloths of Comparative Examples 6 and 7 were prepared by adding an ionic component when producing the quartz glass cloth of Example 1.

[0133] [Table 1]

[0134]

[0135] (Preparation of Curable Resin Composition)

[0136] Prepare by 10 mass parts of cresol novolac type epoxy resin (trade name: EPICLON N-695, DIC Co., Ltd. manufacture), 5 mass parts of phenol novolac resin (trade name: PEHNOLITE TD-2090, DIC Co., Ltd. manufactured by the company), 0.1 parts by mass of imidazole-based curing accelerator (trade name: 2E4MZ, manufactured by Shikoku Chemicals Co., Ltd.), 85 parts by mass of spherical silica (trade name: SC-2050-SE, manufactured by Admate...

Embodiment 1、2

[0146] As shown in Table 2, it can be seen that Examples 1 and 2 show good values in dielectric properties by using high-purity quartz glass cloth. Thus, it was shown that the invention is useful.

Embodiment 3~4、 comparative example 8~14

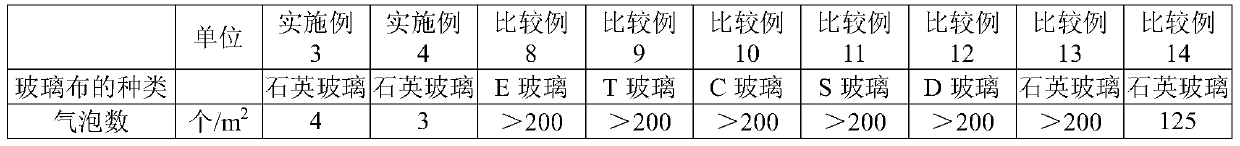

[0151] (glass cloth)

[0152] Glass cloths having a thickness of 0.1 mm were prepared using glasses shown in Table 3 below. The species and bubbles are recorded at the same time. In addition, the glass of Comparative Examples 8 to 13 had too many bubbles, and only 200 cells could be measured.

[0153] [table 3]

[0154]

[0155] (Preparation of film)

[0156] Prepare by 10 mass parts of cresol novolac type epoxy resin (trade name: EPICLON N-695, DIC Co., Ltd. manufacture), 5 mass parts of phenol novolac resin (trade name: PEHNOLITE TD-2090, DIC Co., Ltd. manufactured by the company), 0.1 parts by mass of imidazole-based curing accelerator (trade name: 2E4MZ, manufactured by Shikoku Chemicals Co., Ltd.), 85 parts by mass of spherical silica (trade name: SC-2050-SE, manufactured by Admatechs Co., Ltd. ) and the slurry of the filler-containing epoxy resin composition that the MEK solvent of 50 mass parts forms.

[0157] Each of the glass cloths shown in Table 3 was impreg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com