Method using click chemistry to fast prepare micron-sized porous polymer microspheres

A porous polymer, click chemistry technology, applied in the preparation of microspheres, microcapsule preparations, etc., can solve the problems of high energy consumption, long time, less porous polymer, etc., and achieves simple preparation process, simple steps, and increased specific surface area. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

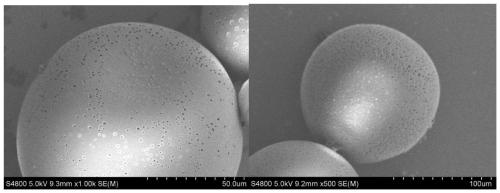

Image

Examples

Embodiment 1

[0032] Embodiment 1: Add 0.1 polyvinylpyrrolidone (PVP), 100g water, 1.53g pentaerythritol tetrakis (3-mercapto propionate) (PETMP) and 1.38g isophorone diisocyanate successively in the container that magnetic stirrer is housed (IPDI), 1g liquid paraffin and 3g chloroform (CHCl 3 ). At the same time, the stirrer was turned on at a speed of 300 rpm, and the stirring time was 10 min. The triethylamine catalyst was added, and the stirring was stopped after 1 min. After standing still for 6 hours, it was centrifuged, washed with petroleum ether, absolute ethanol and water successively, freeze-dried and then freeze-dried to obtain porous polymer microspheres.

Embodiment 2

[0033] Embodiment 2: Add 0.5 polyvinylpyrrolidone (PVP), 100g water, 1.53g pentaerythritol tetrakis (3-mercapto propionate) ester (PETMP) and 1.38g isophorone diisocyanate successively in the container that magnetic stirrer is housed (IPDI), 1g liquid paraffin and 3g chloroform (CHCl 3 ). At the same time, the stirrer was turned on at a speed of 300 rpm, and the stirring time was 10 min. The triethylamine catalyst was added, and the stirring was stopped after 1 min. After standing still for 6 hours, it was centrifuged, washed with petroleum ether, absolute ethanol and water successively, freeze-dried and then freeze-dried to obtain porous polymer microspheres.

Embodiment 3

[0034] Embodiment 3: Add 1g polyvinylpyrrolidone (PVP), 100g water, 1.53g pentaerythritol tetrakis (3-mercaptopropionate) ester (PETMP) and 1.38g isophorone diisocyanate successively in the container that magnetic stirrer is housed (IPDI), 1g liquid paraffin and 3g chloroform (CHCl 3 ). At the same time, the stirrer was turned on at a speed of 300 rpm, and the stirring time was 10 min. The triethylamine catalyst was added, and the stirring was stopped after 1 min. After standing still for 6 hours, it was centrifuged, washed with petroleum ether, absolute ethanol and water successively, freeze-dried and then freeze-dried to obtain porous polymer microspheres.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com