Solid electrolyte and preparation method thereof, and lithium ion battery

A technology of solid electrolytes and electrolytes, applied in solid electrolytes, non-aqueous electrolytes, secondary batteries, etc., can solve the problems of low mechanical properties, high high temperature ionic conductivity, etc., and achieve the effect of high ionic conductivity and high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

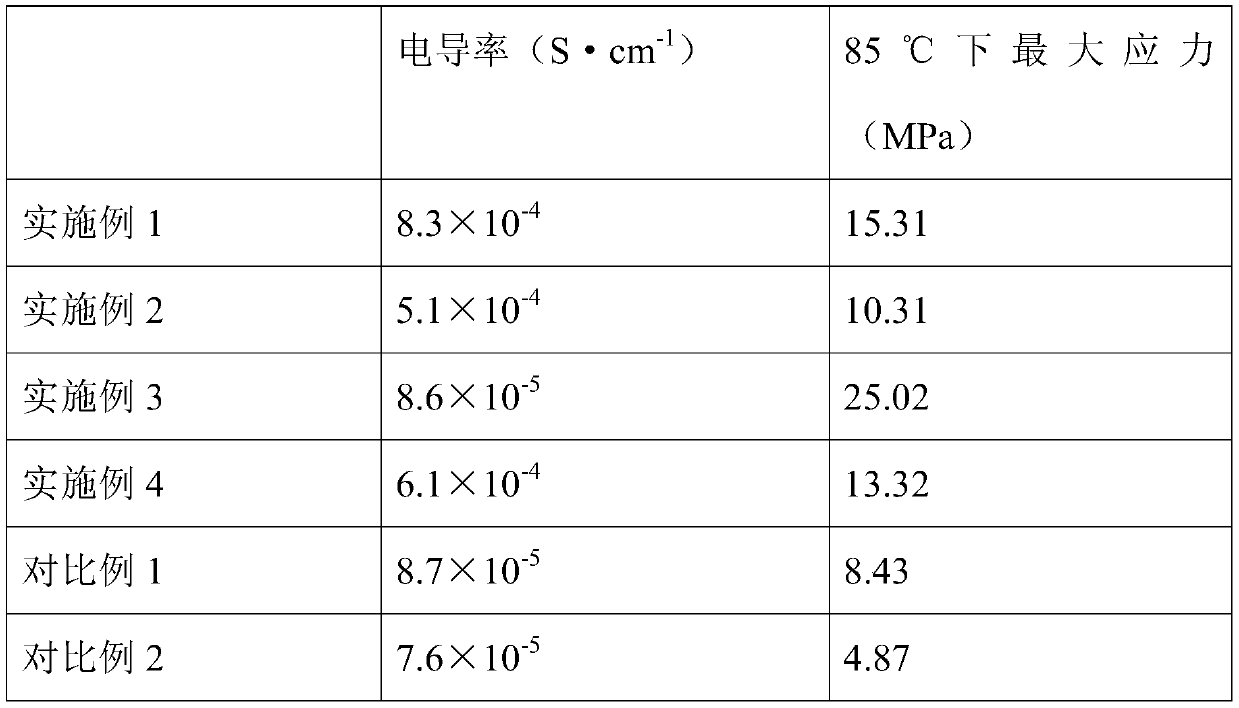

Examples

Embodiment 1

[0067] In this embodiment, a solid electrolyte is prepared according to the following method:

[0068](1) A high-porosity film-like polyethylene substrate with an ordered pore structure was prepared by a thermally induced phase separation method, with a thickness of 5 μm and a porosity of 60%.

[0069] (2) Using ethanol as a solvent, uniformly mix the inorganic filler magnesium oxide to obtain the first mixed solution (the mass concentration of the inorganic filler is 0.2g / L), and place the porous polymer skeleton in the first mixed solution at 25°C Fully soak for 20 minutes to fill the inorganic material in the pore structure of the high-porous polyethylene skeleton to obtain the treated substrate.

[0070] (3) Using dimethylformamide as solvent, polymer electrolyte polyacrylonitrile and lithium salt LiClO 4 Mix evenly to obtain a uniform solution, which is the second mixed solution (the mass concentration of the polymer electrolyte is 0.5 g / L).

[0071] (4) pouring the sec...

Embodiment 2

[0076] In this embodiment, a solid electrolyte is prepared according to the following method:

[0077] (1) A high-porosity membrane-like polypropylene skeleton was prepared by a dry single-drawing method, with a thickness of 12 μm and a porosity of 60%.

[0078] (2) Using DMF as a solvent, uniformly mix the inorganic filler silica to obtain the first mixed solution (the mass concentration of the inorganic filler is 0.4g / L), and place the porous polymer skeleton in the first mixed solution at 15°C Fully soak for 10 minutes, so that the solid electrolyte raw material is completely filled in the pore structure of the polymer skeleton, and the treated substrate is obtained.

[0079] (3) Using acetonitrile as solvent, polymer electrolyte polyvinylidene fluoride and lithium salt LiCF 3 SO 3 Mix evenly to prepare a uniform solution, which is the second mixed solution (the mass concentration of the polymer electrolyte is 1.0 g / L).

[0080] (4) pouring the second mixed solution obta...

Embodiment 3

[0085] (1) A high-porosity film-like polypropylene / polypropylene / polypropylene substrate with an ordered pore structure was prepared by a three-layer co-extrusion method, with a thickness of 25 μm and a porosity of 50%.

[0086] (2) Using acetone as a solvent, uniformly mix the inorganic filler aluminum oxide to obtain the first mixed solution (the mass concentration of the inorganic filler is 0.5 g / L), and place the porous polymer skeleton in the first mixed solution for 35 Fully soak for 30 minutes at ℃, so that the inorganic raw materials are filled in the pore structure of the high-porous polyethylene skeleton, and the treated substrate is obtained.

[0087] (3) With acetone as solvent, the polymer electrolyte polymethyl methacrylate and lithium salt LiAsF 6 Mix evenly to obtain a uniform solution, which is the second mixed solution (the mass concentration of the polymer electrolyte is 2.5 g / L).

[0088] (4) pouring the second mixed solution obtained above into the treate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Areal density | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com