Preparation method of high-orientation communicated BN composite fiber material

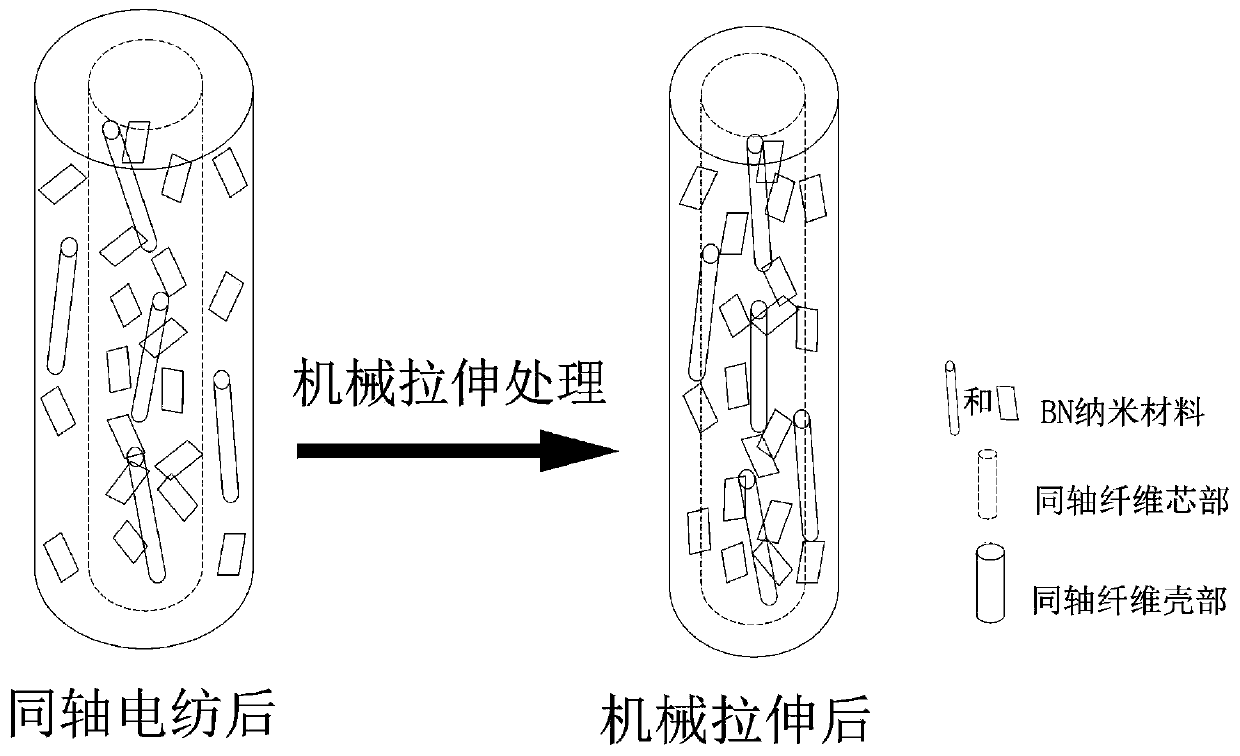

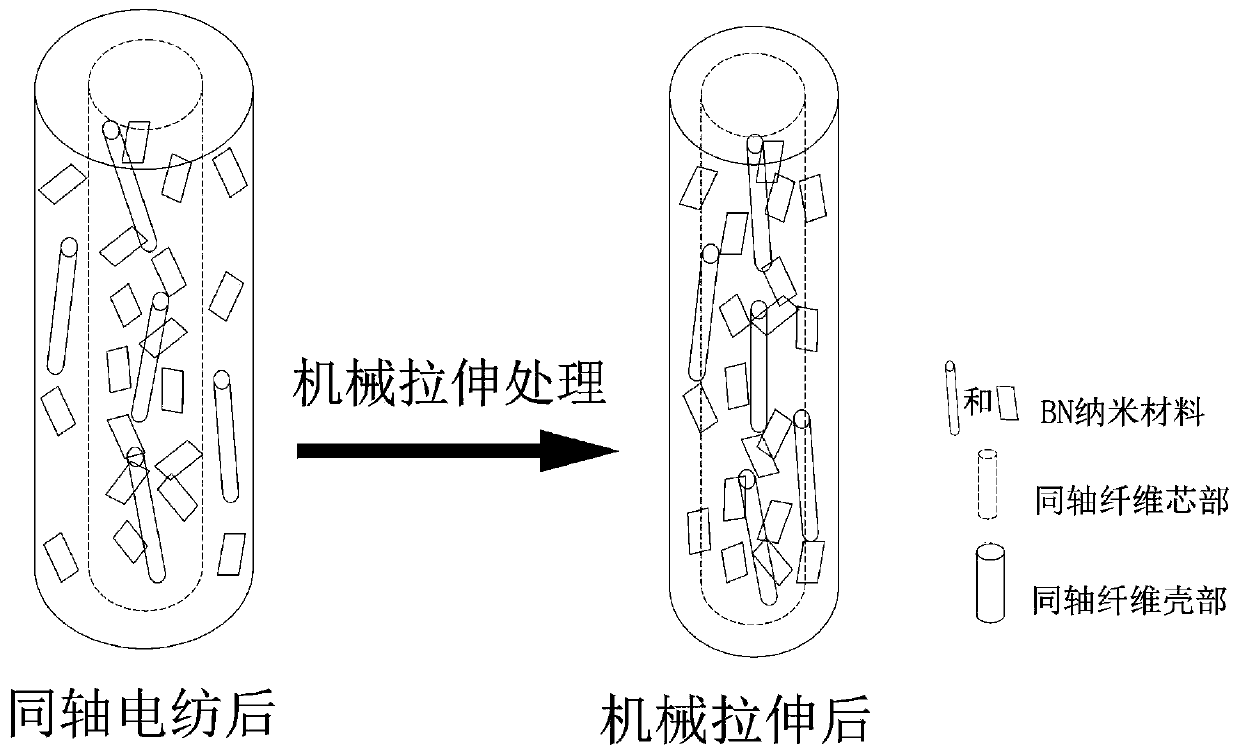

A composite fiber and high-orientation technology, which is applied in fiber processing, fiber chemical characteristics, rayon manufacturing, etc., can solve the problems of poor orientation of BN and incoherent heat conduction paths, and achieve better orientation, better heat dissipation effect, and better heat dissipation effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Implementation 1 A preparation method of highly oriented and connected BN-PVA composite fibers

[0043] Step 1. Completely dissolve 1g of polyvinyl alcohol in 17.4g of solvent water, add 1.6g of BN nano-short fibers with a diameter of 300-400nm and an aspect ratio of 5 and BN nano-sheets with a diameter of 50-100nm. Nano-materials, wherein the ratio of BN nano-short fibers to BN nano-materials is 1:1, and the inner core spinning solution is obtained after mixing; 1.4g polyvinyl alcohol is dissolved in 18.2g solvent water, and 0.4g of the above-mentioned BN nano-materials are added, and mixed evenly Afterwards, shell spinning solution is obtained;

[0044] Step 2, the inner core spinning solution is ultrasonically treated for 10 minutes, and the outer shell spinning solution is ultrasonically treated for 30 minutes;

[0045] Step 3. Put the shell spinning solution into the shell propulsion pump, and the inner core spinning solution into the core propulsion pump. The spi...

Embodiment 2

[0047] Embodiment 2 A kind of preparation method of highly oriented and connected BN-PVP composite fiber

[0048] Step 1, first completely dissolve 1.4g of polyvinylpyrrolidone in 16g of solvent ethanol, add 2.4g of BN nano-short fibers with a diameter of 900-1000nm and an aspect ratio of 100 and BN nano-sheets with a diameter of 150-200nm Mixed BN nanomaterials and 0.2g polyethylene glycol, wherein the ratio of BN nano short fibers to BN nanomaterials is 0.5:1, and after mixing uniformly, inner core spinning solution is obtained; 1.8g polyvinylpyrrolidone is dissolved in In 17.5g of solvent ethanol, add 0.4g of the above-mentioned BN nanomaterials and 0.1g of polyethylene glycol, and mix uniformly to obtain the shell spinning solution;

[0049] Step 2. Ultrasonic treatment of the inner core spinning solution for 15 minutes, and ultrasonic treatment of the outer shell spinning solution for 30 minutes;

[0050] Step 3. Put the shell spinning liquid into the shell propulsion pu...

Embodiment 3

[0052] Embodiment 3 A kind of preparation method of highly oriented and connected BN-PS composite fiber

[0053] Step 1. First, completely dissolve 2.6g of polystyrene in 13g of solvent N,N-dimethylformamide, add 4g of BN nano-short fibers with a diameter of 500-600nm and an aspect ratio of 20 and a diameter of 50-100nm BN nanomaterials mixed with BN nanosheets and 0.4g polyethyleneimine, wherein the ratio of BN nano short fibers to BN nanomaterials is 0.3:1, and the inner core spinning solution is obtained after mixing evenly; 6g polystyrene is completely dissolved In 12.8 g of solvent N,N-dimethylformamide, 1 g of the above-mentioned BN nanomaterial and 0.2 g of polyethyleneimine were added, and mixed uniformly to obtain a shell spinning solution.

[0054] Step 2. Ultrasonic treatment of the inner core spinning solution for 20 minutes, and ultrasonic treatment of the outer shell spinning solution for 30 minutes;

[0055] Step 3. Put the shell spinning liquid into the shell ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com