Metal flake type single-component water-based heavy-duty paint and preparation method thereof

A heavy-duty anti-corrosion, one-component technology, applied in the direction of anti-corrosion coatings, conductive coatings, coatings, etc., can solve the problems of weather resistance and anti-corrosion performance gap, can not be fully satisfied, etc., to achieve strong weather resistance and metal gloss, electrical conductivity Enhanced effect of chemical protection and physical shielding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

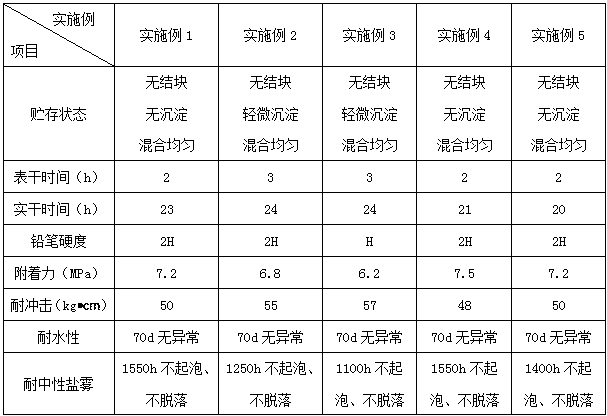

Examples

Embodiment 1

[0032] A metal flake type one-component water-based heavy-duty anti-corrosion coating, comprising the following raw materials in parts by weight:

[0033] 50 parts carbon titanium cage resin;

[0034] 15 parts of water-based aluminum silver paste;

[0035] 2 parts polyvinylpyrrolidone K-30;

[0036] 0.5 parts of sodium carboxymethylcellulose;

[0037] 1 copy of DF-2307;

[0038] 0.5 copies of KYC-616;

[0039] 2 copies of XH-199;

[0040] 25 parts deionized water.

[0041] The preparation method is:

[0042] (1) Accurately weigh the water-based aluminum silver paste and polyvinylpyrrolidone K-30 according to the above ratio, put them into the mixing tank, then add deionized water and defoamer, and then stir in the mixer at 350r / min for 5 minutes to make the water-based aluminum The silver paste is evenly dispersed;

[0043] (2) Continue to add the carbon-titanium cage resin, DF-2307, KYC-616, XH-199 in the above ratio into the mixing tank of step (1), and stir at 200r / ...

Embodiment 2

[0046] 60 parts carbon titanium cage resin;

[0047] 15 parts of water-based aluminum silver paste;

[0048] 3 parts polyvinylpyrrolidone K-30;

[0049] 0.7 parts of sodium carboxymethylcellulose;

[0050] 1 copy of DF-2307;

[0051] 0.6 copies of KYC-616;

[0052] 2 copies of XH-199;

[0053] 20 parts deionized water.

[0054] The preparation method is:

[0055] (1) Accurately weigh the water-based aluminum silver paste and polyvinylpyrrolidone K-30 according to the above ratio, put them into the mixing tank, then add deionized water and defoamer, and then stir in the mixer at 350r / min for 5 minutes to make the water-based aluminum The silver paste is evenly dispersed;

[0056] (2) Continue to add the carbon-titanium cage resin, DF-2307, KYC-616, XH-199 in the above ratio into the mixing tank of step (1), and stir at 200r / min for 10 minutes to ensure uniform mixing and dispersion to obtain a homogeneous pre- polymer emulsion;

[0057] (3) Add carboxymethylcellulose s...

Embodiment 3

[0059] 60 parts carbon titanium cage resin;

[0060] 10 silver dust;

[0061] 2 parts polyvinylpyrrolidone K-30;

[0062] 0.7 parts of sodium carboxymethylcellulose;

[0063] 1 copy of DF-2307;

[0064] 0.6 copies of KYC-616;

[0065] 1.5 copies of XH-199;

[0066] 20 parts deionized water.

[0067] The preparation method is:

[0068] (1) Accurately weigh silver powder and polyvinylpyrrolidone K-30 according to the above ratio, put them into the mixing tank, then add deionized water and defoamer, and then stir in the mixer at 350r / min for 5 minutes to disperse the water-based aluminum silver paste Uniform;

[0069] (2) Continue to add the carbon-titanium cage resin, DF-2307, KYC-616, XH-199 in the above ratio into the mixing tank of step (1), and stir at 200r / min for 10 minutes to ensure uniform mixing and dispersion to obtain a homogeneous pre- polymer emulsion;

[0070] (3) Add carboxymethylcellulose sodium or deionized water to the homogeneous prepolymer emulsion m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com