Tundish nozzle steel retaining groove, tundish nozzle and preparation method

A tundish and steel trough technology, applied in the field of tundish nozzle retaining grooves, can solve problems such as clogging of tundish nozzles, failure to start pouring, low tundish baking temperature and molten steel temperature, etc., so as to extend the flow path and avoid nozzles. The effect of too fast erosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

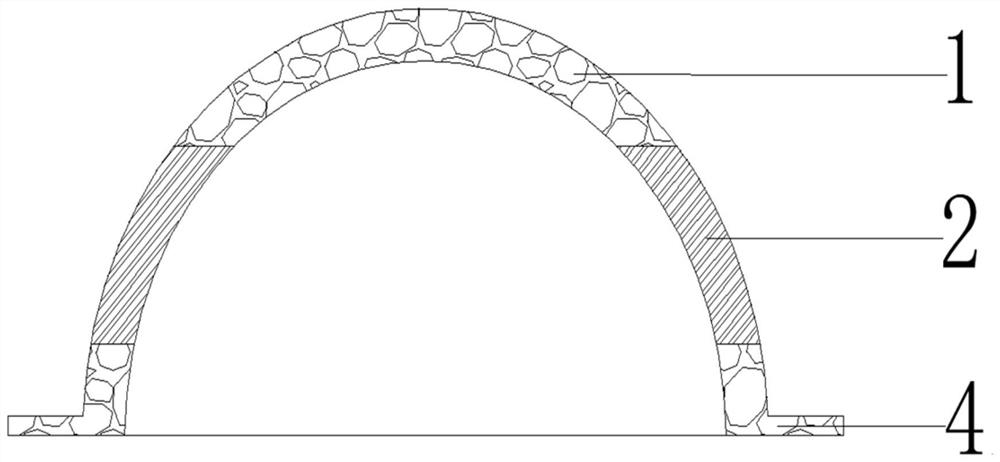

[0044] Such as figure 1 , 2 , 3, and 4, the tundish nozzle retaining steel channel described in this embodiment includes a steel retaining channel main body 1 and a blocking steel plate 2 .

[0045] The main body 1 of the retaining steel channel is an inverted groove structure with a circular arc in cross section. The two ends of the main body 1 of the retaining steel channel are closed. Fitted and connected with the working lining 5 at the bottom of the tundish; 4 (2 pairs) diversion holes are arranged on the arc side wall of the main body 1 of the retaining steel channel, and each pair of diversion holes is symmetrically arranged, and the symmetrical plane is the retaining steel channel The axis of the main body is perpendicular to the plane of the bottom working lining of the tundish, and the height of the bottommost ends of the four diversion holes is higher than the height of the working lining of the tundish bottom;

[0046] The blocking steel plate 2 is arranged in th...

Embodiment 2

[0054] The tundish nozzle described in this embodiment includes the tundish nozzle main body 6 and the tundish nozzle retaining steel channel, the structure of the tundish nozzle retaining steel channel is the same as that in Embodiment 1, and the tundish nozzle retaining steel channel is arranged on the tundish nozzle main body 6, the anti-floating outer edge 4 of the bottom edge of the tundish nozzle retaining steel channel fits with the working lining of the tundish bottom, and works with the tundish bottom through the fixed refractory material 3 arranged on the anti-floating outer edge 4 Lining 5 is connected.

Embodiment 3

[0056] The structure of the tundish nozzle retaining steel channel described in this embodiment is the same as that of embodiment 1, the difference is that the raw materials for preparing the main body of the steel retaining channel include the following components in terms of parts by mass:

[0057] 20 parts of magnesium olive sand particles with a particle size of 3mm-5mm; 30 parts of magnesium olive sand particles with a particle size of 1mm-3mm; 10 parts of DMS-91 particles with a particle size of 0.083mm-1mm; 30 parts of DMS-95 particles with a particle size of ≤0.074mm 15 parts of recycled magnesia-carbon brick particles with a particle size of 0.083mm-1mm; 5 parts of recycled magnesia-carbon brick particles with a particle size of ≤0.074mm; 3 parts of silicon micropowder; 0.2 parts of organic fibers; 0.5 parts of steel fibers; parts; 0.3 parts of sodium hexametaphosphate.

[0058] Its preparation method is identical with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com