Microporous ceramic heater for electronic cigarettes and preparation method of heater

A technology for microporous ceramics and electronic cigarettes, applied in the field of electronic cigarettes, can solve the problems of harming the health of smokers, reaching above 220°C, and not being able to dry burn, etc., and achieve the effects of long service life, fast oil conduction, and fine smoke.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

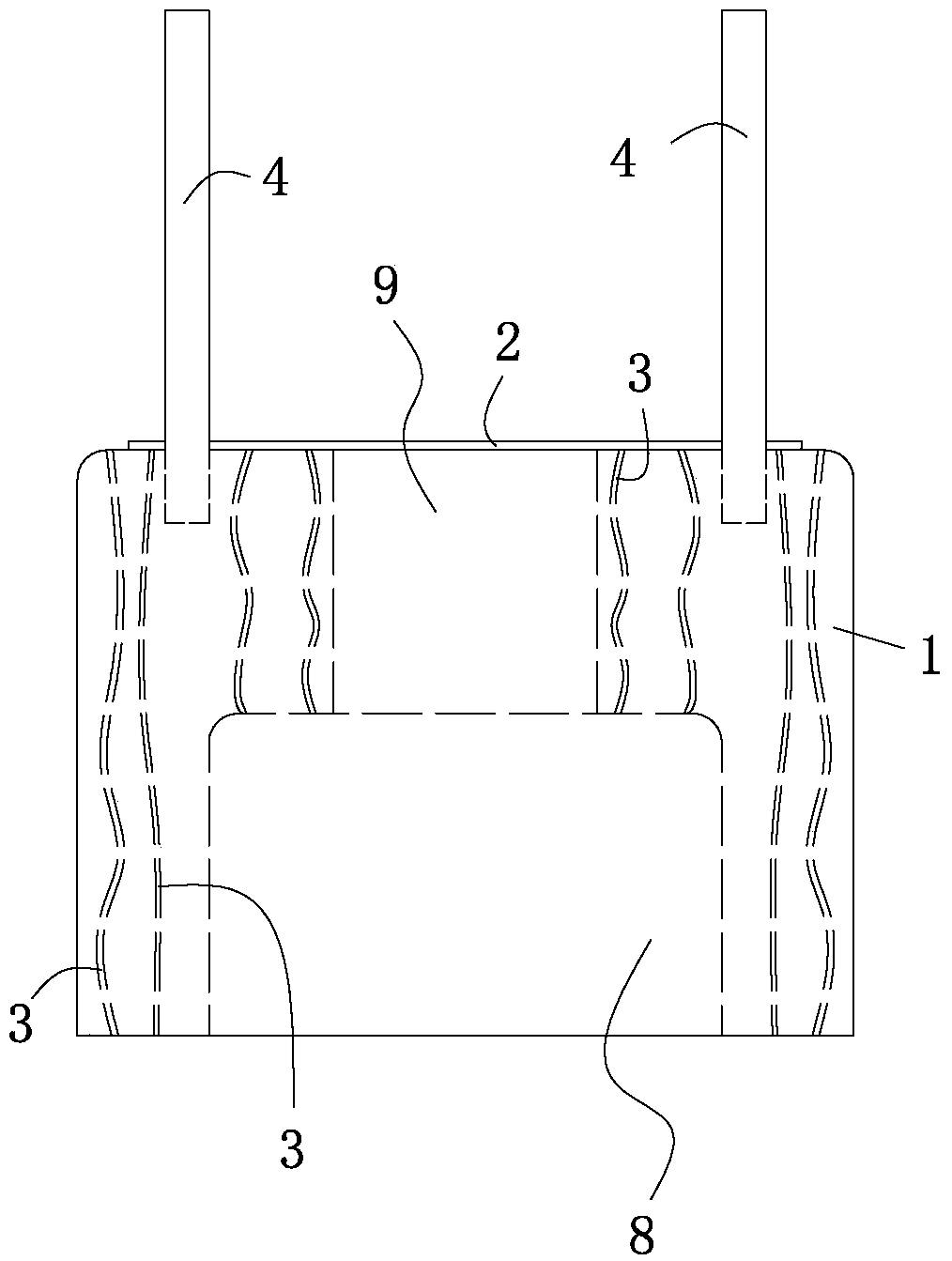

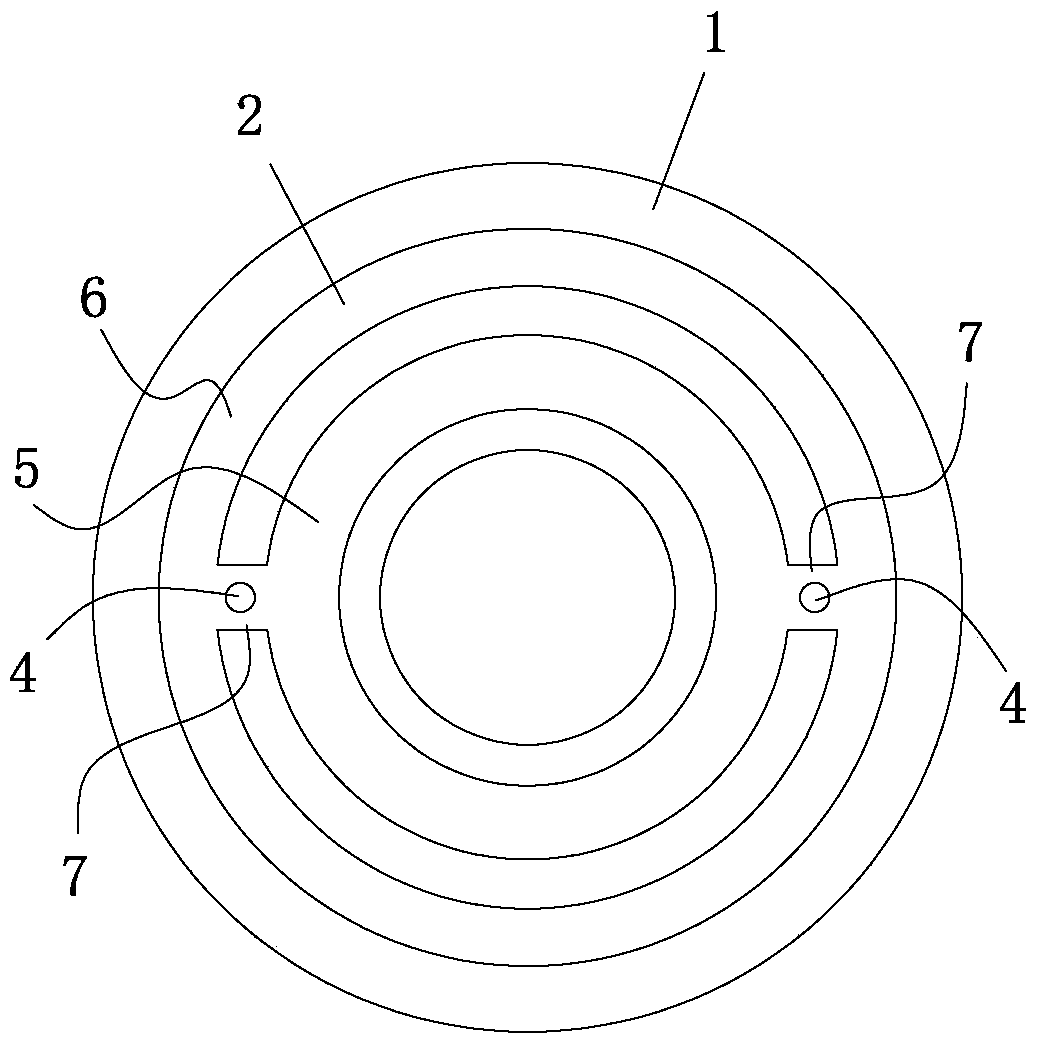

[0063] see figure 1 and figure 2 As shown, a microporous ceramic heater for electronic cigarettes according to the present invention includes a ceramic carrier 1 and a heating film 2 arranged on the ceramic carrier 1, and the ceramic carrier 1 is provided with a plurality of curved perforations running through the ceramic carrier 1 3. The e-liquid from the external electronic cigarette is immersed in the curved perforation 3 , and the heating film 2 is used to heat the ceramic carrier 1 so that the e-liquid in the curved perforation 3 is atomized and escapes out of the ceramic carrier 1 . In this embodiment, the porosity of the ceramic carrier 1 is 35-55%; when the porosity of the ceramic carrier 1 is lower than 35%, the effect of the atomization and escape of the e-liquid from the ceramic carrier 1 is not good, which will cause the electronic cigarette users The experience is poor; when the porosity of the ceramic carrier 1 is higher than 55%, the strength of the ceramic ca...

Embodiment 2

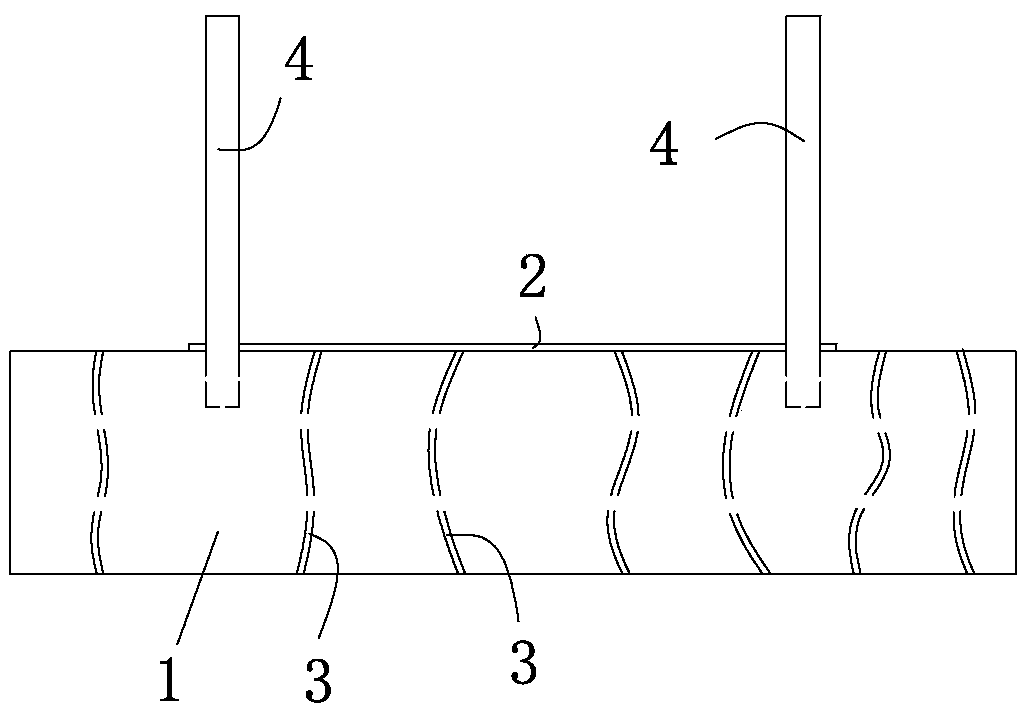

[0073] see image 3 and Figure 4 As shown, the heating film 2 is S-shaped, reducing the area of the heating film 2 on the ceramic carrier 1 per unit area. The left and right ends of the heating film 2 cover the positioning blind holes, and the external tin material is immersed in the electrode lead 4 and the positioning blind holes. In the gap between the hole walls to realize the welding conduction between the electrode lead 4 and the heating film 2, increase the contact area between the heating film 2 and the electrode lead 4, and ensure the stable conduction between the heating film 2 and the electrode lead 4 Pass.

[0074] In this embodiment, the width of both ends of the heating film 2 is larger than the aperture of the positioning blind hole, ensuring that the electrode lead 4 protrudes through the heating film 2 and protrudes into the positioning blind hole, so that the outer edges of the electrode lead 4 are all connected to the heating film 2 .

[0075] The rest ...

Embodiment 3

[0077] see Figure 5 and Figure 6 As shown, the heating film 2 includes a middle part 11 and two solder leg parts 12, the two ends of the middle part 11 are respectively connected with the two solder leg parts 12, and the middle part 11 is S-shaped, reducing the ceramic carrier 1 per unit area. The area of the heat-generating film 2, the width of the welding foot part 12 is greater than the width of the middle part 11, and the two welding foot parts 12 are respectively used to conduct with the two external electrode leads 4. By increasing the width of the solder leg portion 12 , the contact area between the electrode lead 4 and the solder leg portion 12 is ensured, and the stable conduction between the electrode lead 4 and the heating film 2 is ensured.

[0078] The ceramic carrier 1 is provided with an accommodation blind groove 13, which is recessed from the end of the ceramic carrier 1 away from the heating film 2, and the accommodation blind groove 13 is used to accomm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com