A kind of 3D printing white cement-based material and its use method and application

A white cement, 3D printing technology, applied in the direction of additive processing, etc., can solve the problems of thixotropy, rheological setting time can not be reached, printing time cannot be stably controlled, 3D printing structure is easy to collapse, etc., to inhibit the later collapse phenomenon, improve rheology and thixotropy, and achieve the effect of stable regulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

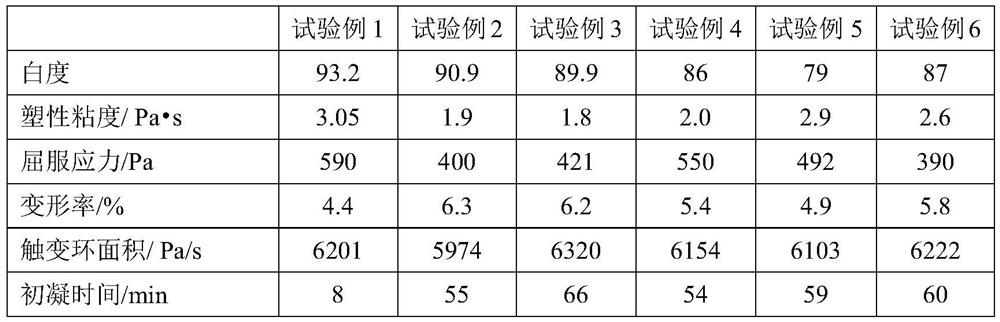

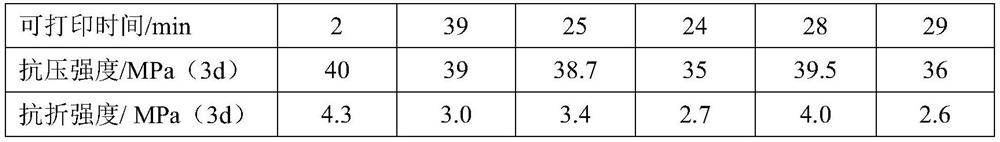

Examples

Embodiment 1

[0041]A preparation of 3D printing white cement-based material, including the following components in parts by weight: 650 parts of basic oxides, 440 parts of phosphate components, 110 parts of retarders, 15 parts of fibers, 12 parts of desulfurized gypsum, 10 parts of titanium dioxide, 18 parts of limestone powder, 17 parts of emulsion, 330 parts of water.

[0042] The basic oxide is magnesium oxide obtained by calcining magnesite at 1700°C. The phosphate component is ammonium dihydrogen phosphate; the retarder is borax; the fiber is polypropylene fiber, and the emulsion is a mixture of styrene-acrylic emulsion and polyvinyl acetate emulsion, and the styrene-acrylic emulsion and polyvinyl acetate emulsion The mixing mass ratio of vinyl acetate emulsion is 2.1:1 in sequence.

Embodiment 2

[0044] A preparation of 3D printing white cement-based material, including the following components in parts by weight: 680 parts of basic oxides, 450 parts of phosphate components, 80 parts of retarders, 22 parts of fibers, 13 parts of desulfurized gypsum, 13 parts of titanium dioxide, 25 parts of limestone powder, 23 parts of emulsion, 380 parts of water.

[0045] The basic oxide is magnesium oxide obtained by calcining magnesite at 1700°C. The phosphate component is potassium dihydrogen phosphate; the retarder is boric acid; the fiber is polypropylene fiber, and the emulsion is a mixture of styrene-acrylic emulsion and polyvinyl acetate emulsion, and the styrene-acrylic emulsion and polyvinyl acetate emulsion The mixing mass ratio of vinyl acetate emulsion is 2.4:1 in sequence.

Embodiment 3

[0047] A preparation of 3D printing white cement-based material, including the following components in parts by weight: 690 parts of basic oxides, 410 parts of phosphate components, 100 parts of retarders, 12 parts of fibers, 20 parts of desulfurized gypsum, 10 parts of titanium dioxide, 16 parts of limestone powder, 25 parts of emulsion, 370 parts of water.

[0048] The basic oxide is magnesium oxide obtained by calcining magnesite at 1700°C. The phosphate component is potassium dihydrogen phosphate; the retarder is boric acid; the fiber is polyethylene fiber, and the emulsion is a mixture of styrene-acrylic emulsion and polyvinyl acetate emulsion, and styrene-acrylic emulsion and polyvinyl acetate emulsion The mixing mass ratio of vinyl acetate emulsion is 2.7:1 in sequence.

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

| deformation rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com