A kind of preparation method of spherical silica

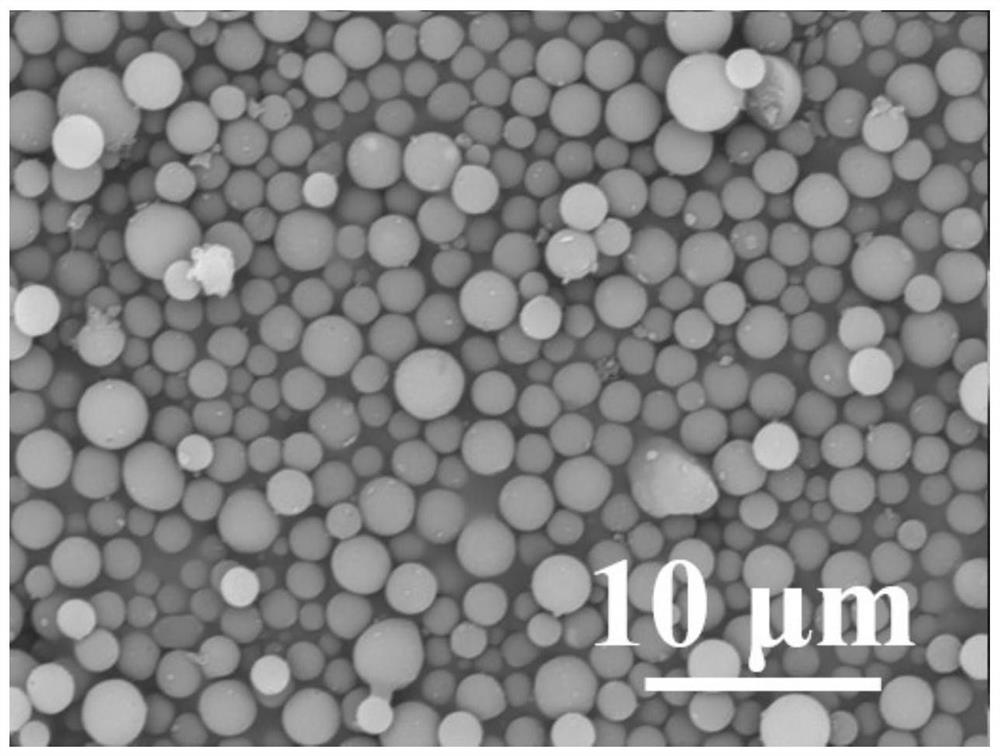

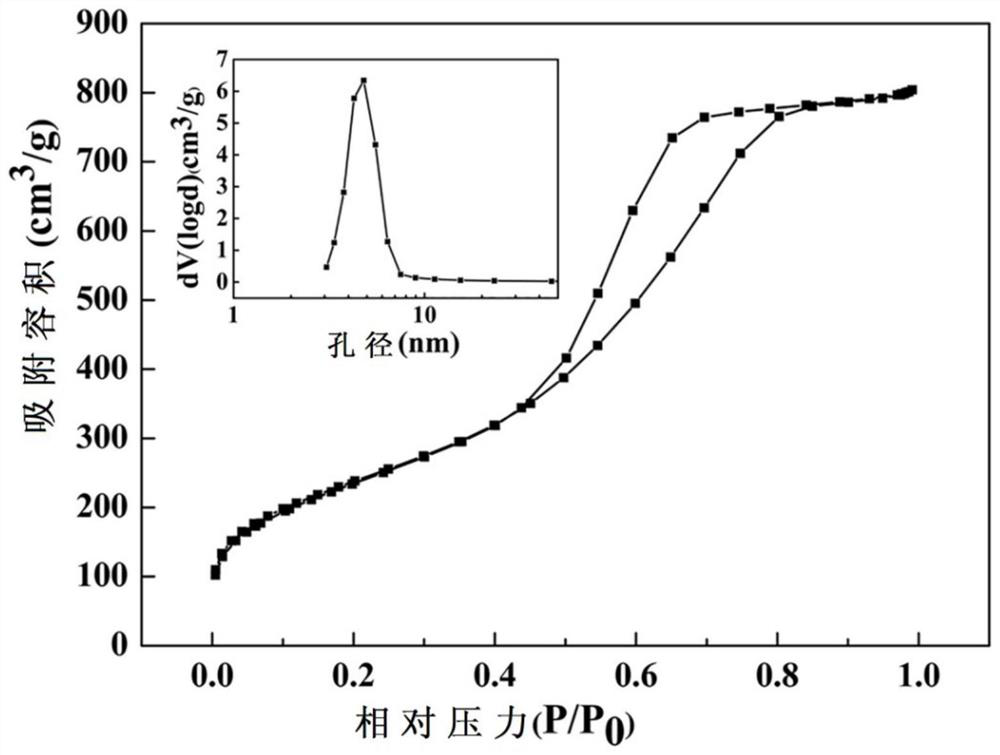

A spherical silica and carbon dioxide technology, applied in the direction of silica, silicon oxide, carbonate preparations, etc., can solve problems such as failure to achieve good application effects, difficulty in large-scale industrial production, difficulty in processing and reuse, etc. Achieve the effects of low production cost, narrow particle size distribution and large pore volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

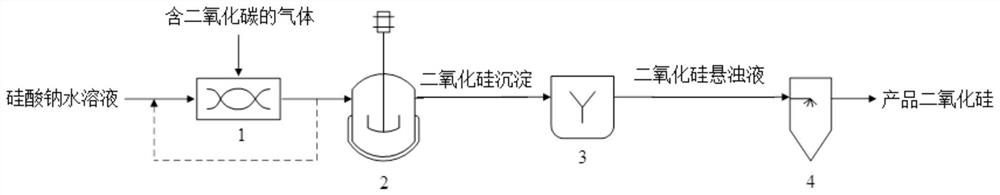

[0035] Spherical silica was prepared as follows:

[0036] (1) Dissolve 6 g of sodium silicate nonahydrate in 100 mL of water, and stir to dissolve at room temperature to obtain an aqueous sodium silicate solution.

[0037] (2) the sodium silicate aqueous solution obtained in step (1) and pure carbon dioxide gas are simultaneously passed into the membrane dispersion microreactor, and the average pore diameter of the dispersed membrane is 0.5 μm; the volume flow ratio of carbon dioxide gas to the sodium silicate aqueous solution is 5:1, The obtained reaction solution was recycled and fed, and the carbonization reaction temperature was 20° C. When the pH value of the reaction solution was 8, ventilation was stopped.

[0038] (3) The reaction solution obtained in step (2) enters the aging reaction kettle, and is aged in a water bath at 80° C. for 10 minutes without stirring during the aging process.

[0039] (4) The precipitate is obtained by centrifugation, washed with water, an...

Embodiment 2

[0042] Spherical silica was prepared as follows:

[0043] (1) Dissolve 6 g of sodium silicate nonahydrate in 300 mL of water, and stir to dissolve at room temperature to obtain an aqueous sodium silicate solution.

[0044] (2) The sodium silicate aqueous solution obtained in step (1) and pure carbon dioxide gas are simultaneously introduced into the membrane dispersion microreactor, and the average pore diameter of the dispersion membrane is 5 μm. The sodium silicate aqueous solution is fed in a single feeding, the volume flow ratio of carbon dioxide gas to the sodium silicate aqueous solution is 2:1, the carbonization reaction temperature is 40 ° C, and when the pH value of the reaction solution is 8, the ventilation is stopped.

[0045] (3) The reaction solution obtained in step (2) enters the aging reaction kettle, and is aged in a 100° C. water bath for 6 hours without stirring during the aging process.

[0046] (4) Centrifugation and separation to obtain a precipitate, w...

Embodiment 3

[0049] Spherical silica was prepared as follows:

[0050] (1) Dissolve 6 g of sodium silicate nonahydrate in 100 mL of water, and stir to dissolve at room temperature to obtain an aqueous sodium silicate solution.

[0051] (2) The sodium silicate aqueous solution obtained in step (1) and the mixed gas (50% carbon dioxide + 50% nitrogen) are simultaneously introduced into the membrane dispersion microreactor, and the average pore diameter of the dispersion membrane is 50 μm. The obtained reaction solution was recycled and fed, the volume flow ratio of the mixed gas and the aqueous sodium silicate solution was 10:1, the carbonization reaction temperature was 15°C, and when the pH value of the reaction solution was 8, ventilation was stopped.

[0052] (3) The reaction solution obtained in step (2) enters the aging reaction kettle, and is aged in a water bath at 85° C. for 10 min, and the stirring speed is 500 rpm during the aging process.

[0053] (4) Centrifugation and separation...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com