Catalyst for preparing corresponding olefins through dehydrogenation of low-carbon alkanes and application of catalyst

A technology of low-carbon alkanes and catalysts, which is applied in the field of catalysts for preparing corresponding olefins from the dehydrogenation of low-carbon alkanes. It can solve the problems of irreversible loss of catalysts, reduction of single-pass conversion rate, metal sintering loss, etc., achieve good industrial application prospects, and maintain catalyst activity. , the effect of suppressing the problem of sintering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

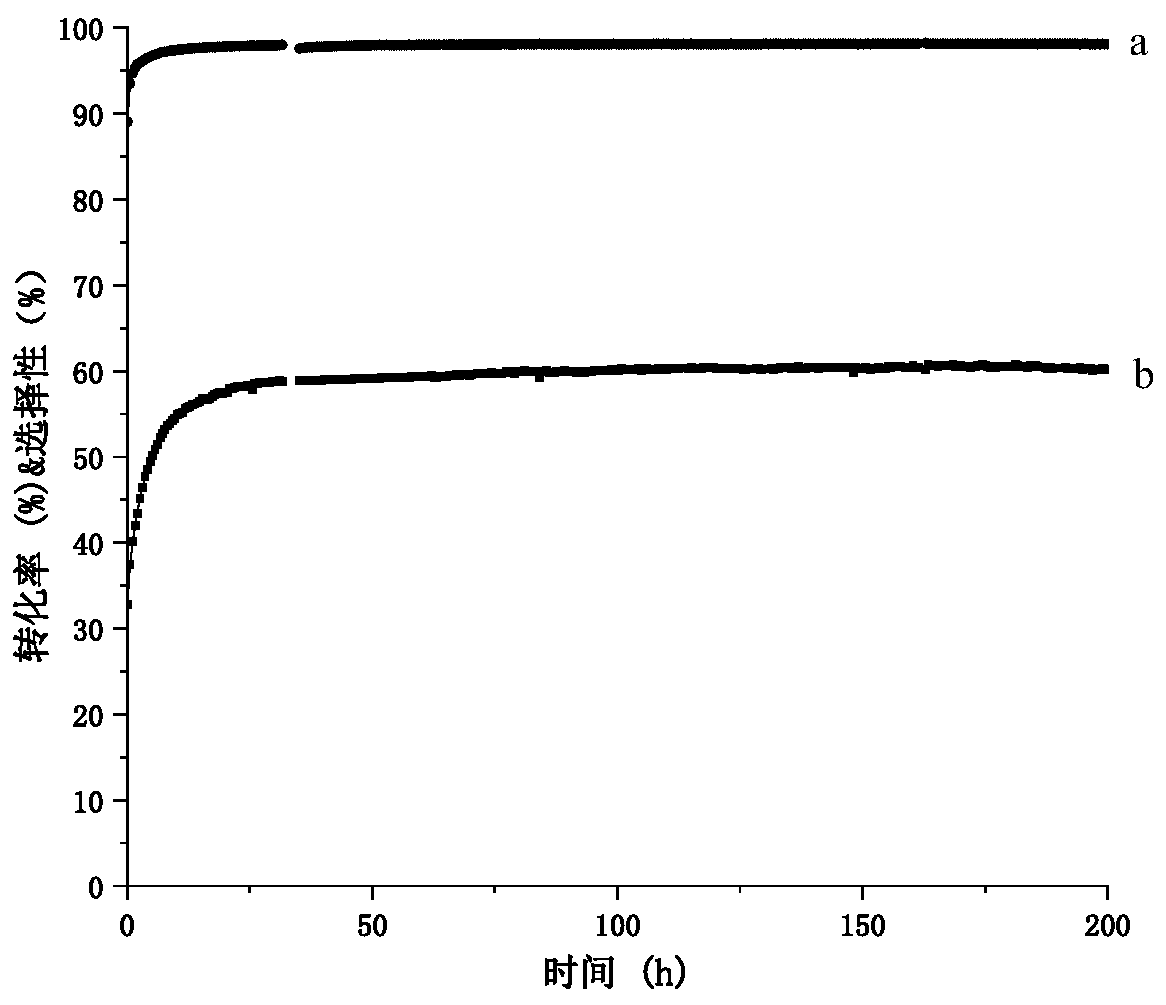

[0026] Take 0.22g 0.4%Pt-2%Cu@MOR (SAR=20) catalyst of 30~60 meshes, put it into a quartz reaction tube (inner diameter 10mm), at a flow rate of 15ml min -1 Under nitrogen atmosphere, at 10°C min -1The heating rate was heated from room temperature to 550 °C and kept for 30 min. The catalytic reaction is carried out in a fixed-bed reactor at normal pressure, and the reaction conditions are: the reaction gas is butane and nitrogen, and the flow rate is 30ml min -1 , 80ml min -1 , the reaction temperature is 550° C., and the reaction pressure is normal pressure. The reaction products were analyzed online by gas chromatography. The catalytic performance (T = 550°C) of the 0.4%Pt-2%Cu@MOR catalyst is shown in Table 1.

[0027] Table 1

[0028] Butane conversion (%) 64 Butene selectivity (%) 99.1 Methane selectivity (%) 0.3 Ethane selectivity (%) 0.6 Ethylene selectivity (%) 0

Embodiment 2

[0030] Take 0.22g 0.8%Pd-1.6%Ga@MCM-22 (SAR=30) catalyst of 30~60 meshes, put it into a quartz reaction tube (inner diameter 10mm), at a flow rate of 15ml min -1 Under nitrogen atmosphere, at 10°C min -1 The heating rate was heated from room temperature to 600 °C and kept for 30 min. The catalytic reaction was carried out in a fixed-bed reactor at normal pressure, and the reaction conditions were: the reaction gas was ethane and argon, and the flow rates were 5ml min -1 , 15ml min -1 , the reaction temperature is 750°C and normal pressure. The reaction products were analyzed online by gas chromatography. The catalytic performance (T=750°C) of 0.8%Pd-1.6%Ga@MCM-22 catalyst is shown in Table 2.

[0031] Table 2

[0032] Ethane conversion rate (%) 30 Ethylene selectivity (%) 85.4 Methane selectivity (%) 14.5

Embodiment 3

[0034] Take 0.22g 0.5%Rh-2%Zn@S-1 catalyst of 30~60 meshes, put it into a quartz reaction tube (inner diameter 10mm), at a flow rate of 15ml min -1 Under nitrogen atmosphere, at 10°C min -1 The heating rate was heated from room temperature to 600 °C and kept for 30 min. The catalytic reaction is carried out in a fixed-bed reactor at normal pressure, and the reaction conditions are as follows: the reaction gas is propane and helium, and the flow rate is 20ml min -1 、60ml min -1 , the reaction temperature is 600°C, and the reactor is at normal pressure. The reaction products were analyzed online by gas chromatography. The catalytic performance of the 0.5%Rh-2%Zn@S-1 catalyst (T = 600°C) is shown in Table 3.

[0035] table 3

[0036] Propane Conversion (%) 65 Propylene selectivity (%) 98.4 Methane selectivity (%) 0.5 Ethane selectivity (%) 1.0 Ethylene selectivity (%) 0.1

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com