Scratch-proof self-release ink-jet printing UV resin and preparation method thereof

An inkjet printing and resin technology, which is applied in the field of anti-scratch self-release inkjet printing UV resin and its preparation, can solve the problems of poor compatibility, affecting the transparency and appearance of the coating, and the ink is difficult to adhere firmly. Effect of low surface friction coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

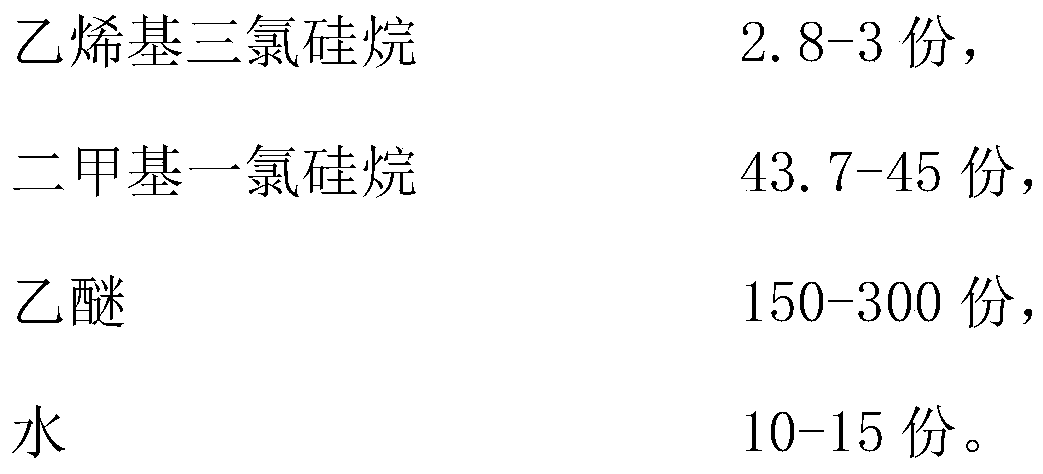

[0030] (1) Preparation of organosilicon active body with double bond and silicon-hydrogen bond at the end group:

[0031] Weigh 2.8g of vinyltrichlorosilane, 45g of dimethylmonochlorosilane, 150g of diethyl ether and 10g of water into the reaction kettle, stir at 30°C for 6 hours; raise the temperature to 100°C, vacuumize to remove water and solvent ether , to obtain a silicone active body with a double bond and a silicon-hydrogen bond at the end group.

[0032] (2) Preparation of hydroxyl-containing rigid hyperbranched polyester UV resin:

[0033] Weigh 134g of dimethylolpropionic acid, 148g of phthalic anhydride and 0.282g of triphenylphosphine into the reaction kettle, stir, heat up to 90°C in 30 minutes, and react for 8 hours to obtain a carboxyl-terminated hyperbranched polyester containing a rigid skeleton; 28.2 g of glycidyl acrylate was added, and the reaction was carried out at a temperature of 90° C. for 4 hours to prepare a hydroxyl-containing rigid hyperbranched p...

Embodiment 2

[0037] (1) Preparation of organosilicon active body with double bond and silicon-hydrogen bond at the end group:

[0038] Weigh 3g of vinyltrichlorosilane, 43.7g of dimethylmonochlorosilane, 300g of ether and 15g of water into the reaction kettle, stir at 50°C for 4 hours; raise the temperature to 150°C, remove water and solvent ether under reduced pressure , to prepare hyperbranched polysiloxane active body.

[0039] (2) Preparation of hydroxyl-containing rigid hyperbranched polyester UV resin:

[0040] Weigh 134g of dimethylolpropionic acid, 166g of methyl tetrahydrophthalic anhydride and 6g of triethylamine into the reaction kettle, stir, heat up to 130°C in 30 minutes, and react for 4 hours to obtain a terminal with a rigid skeleton. Carboxyl hyperbranched polyester: add 105 g of glycidyl methacrylate, and heat-preserve at 130° C. for 2 hours to prepare a hydroxyl-containing rigid hyperbranched polyester UV resin.

[0041] (3) Preparation of anti-scratch self-release ink...

Embodiment 3

[0044] (1) Preparation of organosilicon active body with double bond and silicon-hydrogen bond at the end group:

[0045] Weigh 3g of vinyltrichlorosilane, 45g of dimethylmonochlorosilane, 300g of diethyl ether and 15g of water into the reaction kettle, stir at 50°C for 4 hours; raise the temperature to 150°C, remove water and solvent ether by vacuuming under reduced pressure, A hyperbranched polysiloxane active body is prepared.

[0046] (2) Preparation of hydroxyl-containing rigid hyperbranched polyester UV resin:

[0047] Weigh 134g of dimethylolpropionic acid, 152g of tetrahydrophthalic anhydride and 2.86g of ammonium chloride into the reaction kettle, stir, heat up to 110°C in 30 minutes, and react for 6 hours to obtain a carboxyl-terminated hyperbranched polyester containing a rigid skeleton Add 56 g of glycidyl methacrylate, and heat preservation reaction at 110° C. for 3 hours to obtain a hydroxyl-containing rigid hyperbranched polyester UV resin.

[0048] (3) Prepar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com