Production method of food additive sodium benzoate

A food additive, sodium benzoate technology, applied in chemical instruments and methods, separation/purification of carboxylic acid compounds, preparation of carboxylate, etc., can solve the problems of lengthy steps, low production efficiency, and long operation time of melt crystallization, etc. Reach the effect of reducing equipment investment, improving utilization rate and yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A kind of production method of food additive sodium benzoate:

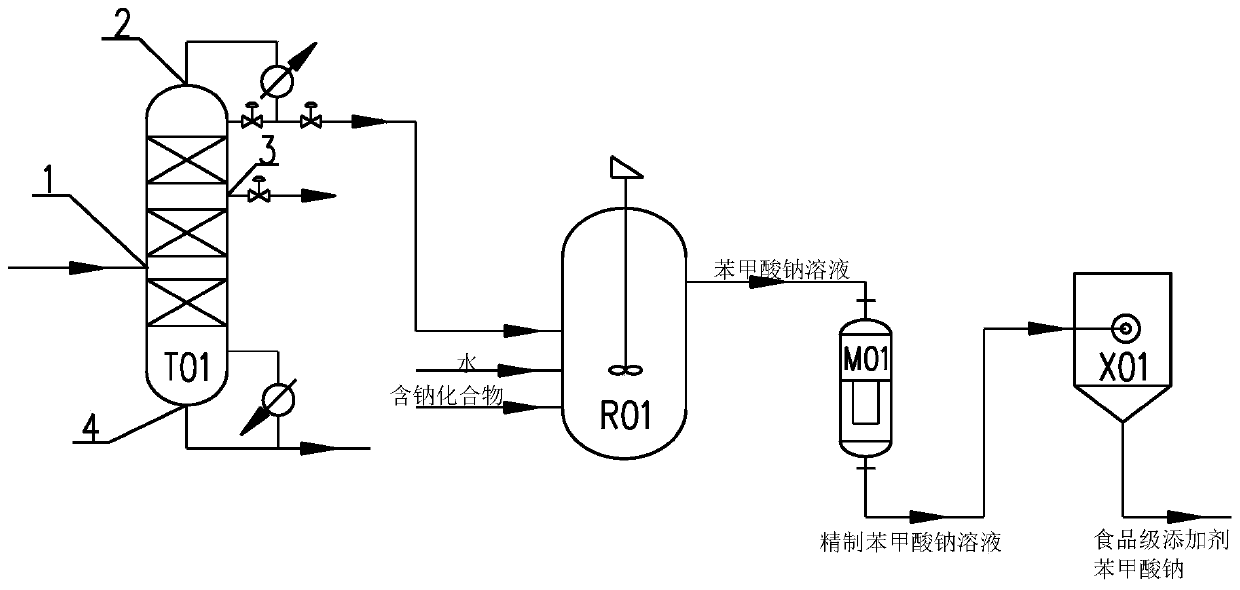

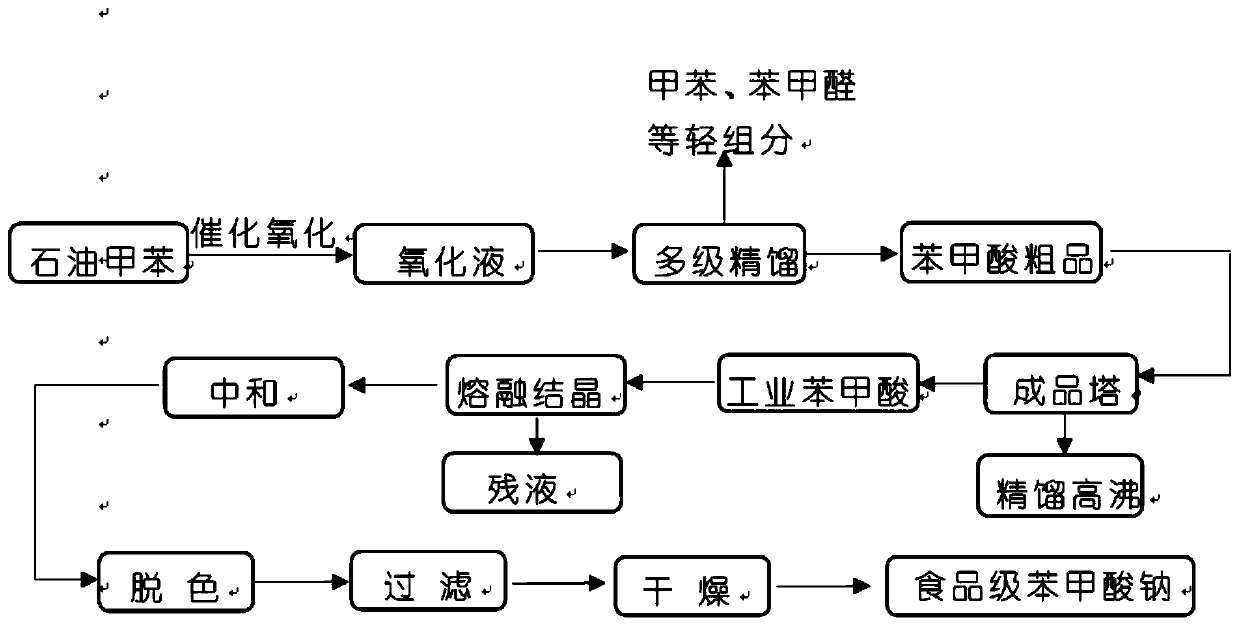

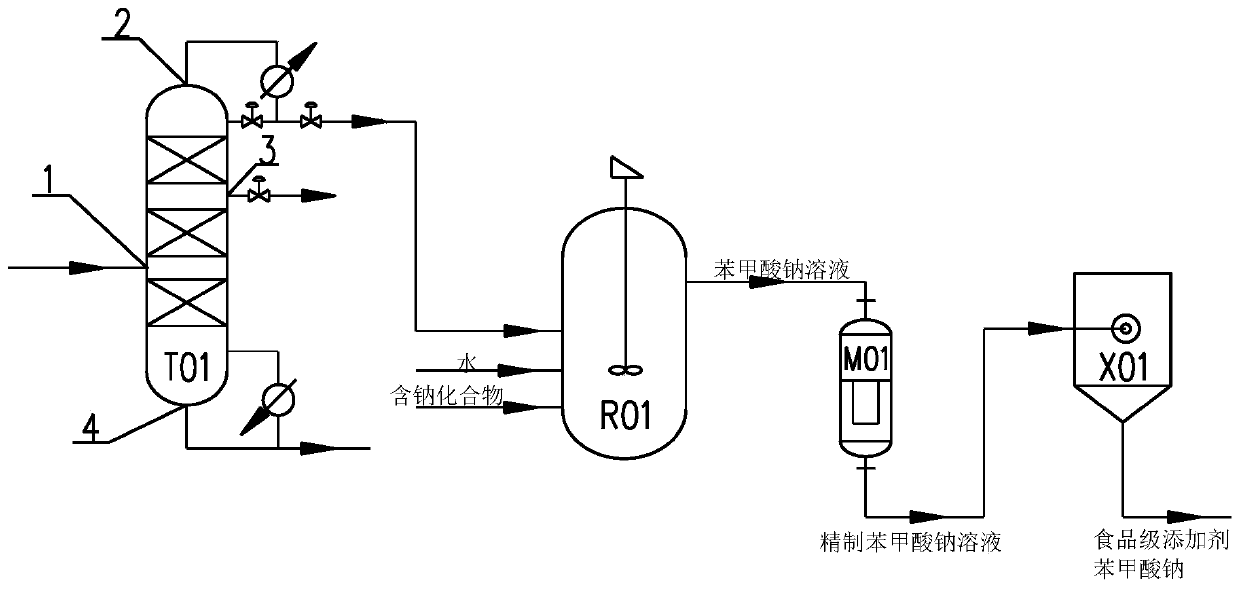

[0027] In this example, petroleum toluene produced by a chemical plant is used as the raw material. After the petroleum toluene is subjected to liquid-phase catalytic air oxidation, the oxidized liquid containing benzoic acid is obtained. As for the crude benzoic acid, after detection, the content of benzoic acid in the crude benzoic acid is 91.22%, the content of phthalic acid is 0.21%, the content of benzyl benzoate is 5.82% and the remainder is high boiling matter. then use figure 1 Process flow to produce food additive sodium benzoate.

[0028] 1) benzoic acid crude product is dropped in the rectifying tower T01 tower still of band side line discharge, control rectifying tower T01 pressure is 7kpa, when feed liquid level reaches tower still height 50% place starts heating, control tower top temperature is 165°C, the temperature of the side line outlet is 170°C, the temperature of the tower kettle is 2...

Embodiment 2

[0035] A kind of production method of food additive sodium benzoate:

[0036] In this example, the petroleum toluene produced by a certain chemical plant is used as the raw material. After the petroleum toluene is subjected to liquid-phase catalytic air oxidation, the oxidized liquid containing benzoic acid is obtained. The oxidized liquid passes through a plurality of series-connected rectification towers to obtain the initially separated benzoic acid. Crude product, after testing, the content of benzoic acid in the crude product of benzoic acid is 93.18%, the content of phthalic acid is 0.18%, the content of benzyl benzoate is 4.50% and the high boiler of the balance. then use figure 1 Process flow to produce food-grade additive sodium benzoate.

[0037] 1) benzoic acid crude product enters in the rectifying tower T01 tower still of band side line discharge, control rectifying tower T01 pressure is 8kpa, when feed liquid level reaches tower still height 70% place starts hea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com