Porous membrane reinforced polymer-plastic crystal solid electrolyte membrane, its preparation method and application

A technology of solid electrolyte membrane and solid electrolyte layer, applied in solid electrolyte, non-aqueous electrolyte, circuit, etc., can solve the problems of increasing battery volume energy density, great influence on conductivity, poor mechanical properties, etc., and achieve improved cycle stability , Improve the mechanical properties, the effect of good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] Another aspect of the embodiments of the present invention provides a method for preparing a porous membrane-reinforced polymer-plastic crystal solid electrolyte membrane, comprising:

[0042] Uniformly mixing the polymer, inorganic lithium salt and plastic crystal compound in a low boiling point solvent to form a homogeneous solution;

[0043] The homogeneous solution is applied to the surface of the porous membrane, and the solvent is removed, followed by vacuum drying to obtain a polymer-plastic solid electrolyte membrane reinforced by the porous membrane.

[0044] Further, in some more specific implementation cases, the porous membrane-reinforced polymer-plastic crystal solid electrolyte membrane can be supported by a porous membrane, and a homogeneous solution of a polymer, an inorganic lithium salt, and a plastic crystal compound It is prepared by coating on both sides of the porous membrane and drying in vacuum.

[0045] In some preferred embodiments, the weight...

Embodiment 1

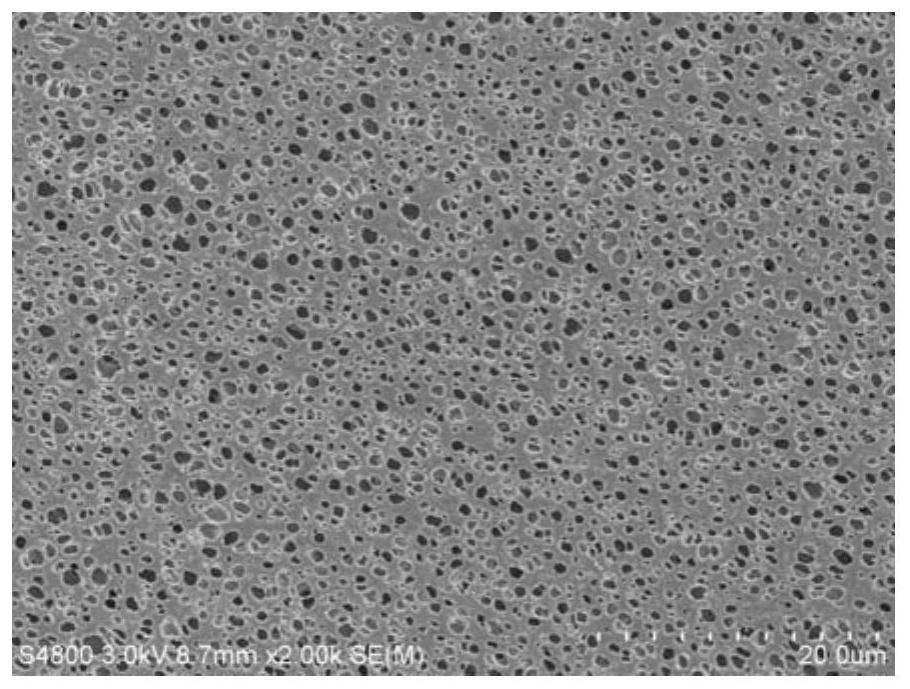

[0073] Embodiment 1 This embodiment relates to a kind of preparation technology of the flexible (PVDF-HFP) / LiTFSI / succinonitrile solid electrolyte membrane that the PVDF-HFP porous membrane that content of lithium salt is 20wt% strengthens, and it comprises:

[0074] Weigh 2g of lithium salt LiTFSI and 6g of plastic crystal compound succinonitrile into N,N-dimethylformamide, after it is completely dissolved, add 2g of polymer (PVDF-HFP) and stir overnight to completely dissolve , dispersed evenly, and then dried the PVDF-HFP porous membrane with a thickness of 10 μm at 80 ° C, put it into a stainless steel abrasive tool of the same size, poured the above mixed solution on the PVDF-HFP porous membrane, and protected it under Ar gas The solvent was evaporated at 50°C and dried for 2 days in a vacuum oven at 50°C to prepare a PVDF-HFP porous membrane reinforced (PVDF-HFP) / LiTFSI / succinonitrile solid electrolyte membrane (named PPCE-1) with a thickness of 100 μm. The mass percenta...

Embodiment 2

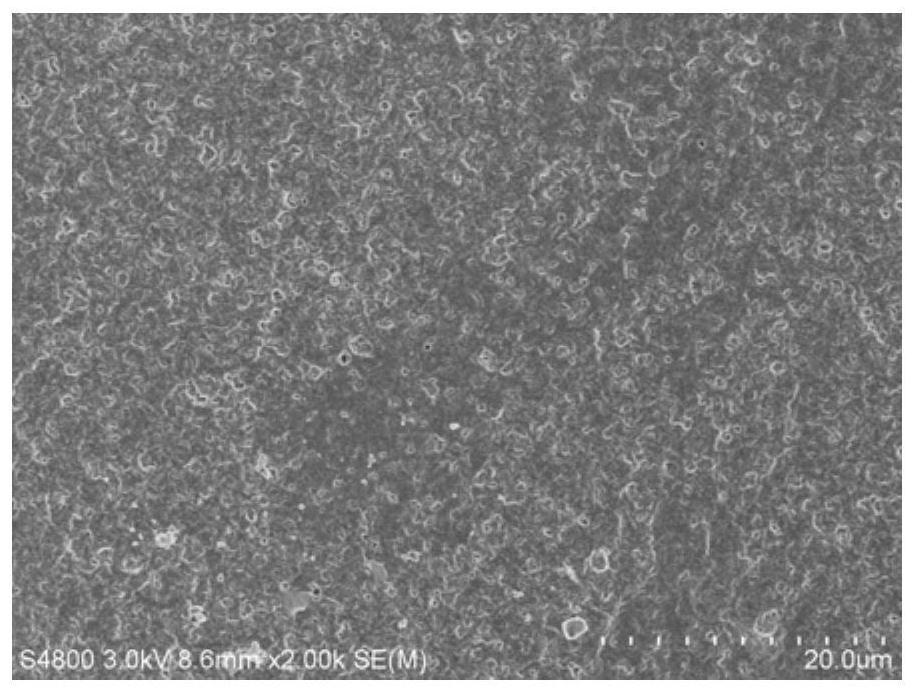

[0075] Embodiment 2 This embodiment relates to a preparation process of a flexible (PVDF-HFP) / LiTFSI / succinonitrile solid electrolyte membrane reinforced by a PVDF-HFP porous membrane with a lithium salt content of 30 wt%, which includes:

[0076] Weigh 3g of lithium salt LiTFSI and 5g of succinonitrile into N,N-dimethylformamide, after it is completely dissolved, add 2g of polymer (PVDF-HFP), stir overnight to make it all dissolve and disperse evenly , then dry the PVDF-HFP porous membrane with a thickness of 10 μm at 80°C, put it into a stainless steel grinding tool of the same size, pour the above mixed solution on the PVDF-HFP porous membrane, and evaporate the solvent under the protection of Ar gas , dried in a vacuum oven at 50°C for 2 days to prepare a 100 μm PVDF-HFP porous membrane reinforced (PVDF-HFP) / LiTFSI / succinonitrile solid electrolyte membrane (named PPCE-2), wherein the mass percentages were 20wt% PVDF-HFP, 30wt% LiTFSI, 50wt% SN.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com