Production technology for controlling B-type inclusions in pipeline steel

A technology for production process and inclusions, which is applied in the field of production process for controlling Type B inclusions in pipeline steel, can solve the problems of poor removal effect, low processing efficiency, and high energy consumption of Type B inclusions, and achieve reduced impact and simplified Production process, the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

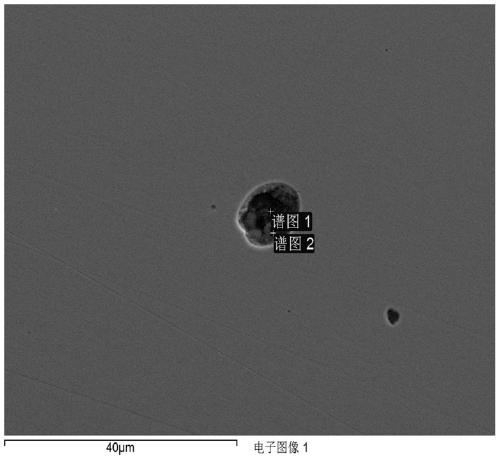

Image

Examples

Embodiment 1

[0072] 210 tons of molten iron are subjected to KR desulfurization treatment, so that the sulfur content in the molten iron is controlled below 50ppm; then the top-bottom combined blowing converter is used to make steel, and the impact of molten steel is used to add 600Kg of lime + 200Kg of aluminum particles in the process of tapping for pre-slagging; Under the condition of controlling the flow rate of bottom-blowing argon gas to 200NL / min, turn on the power and raise the temperature to 1620°C, increase the flow rate of bottom-blowing protective gas to partially expose the molten steel, and add 525Kg of rare earth slag reforming agent to the exposed part of the molten steel for LF refining. After testing the composition and temperature of the molten steel to pass the test, carry out the 8-10min soft blowing inclusion floating process operation. Pipeline steel products are obtained through casting and rolling processes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com