A device and method for preparing high-performance magnesium alloys with large plastic deformation

A large plastic deformation, magnesium alloy technology, applied in forging/pressing/hammer devices, manufacturing tools, metal extrusion dies, etc., can solve the problems of large free forging allowance, magnesium alloy folding, cracks, etc., and achieve machining allowance Less, less tensile stress, the effect of eliminating internal defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

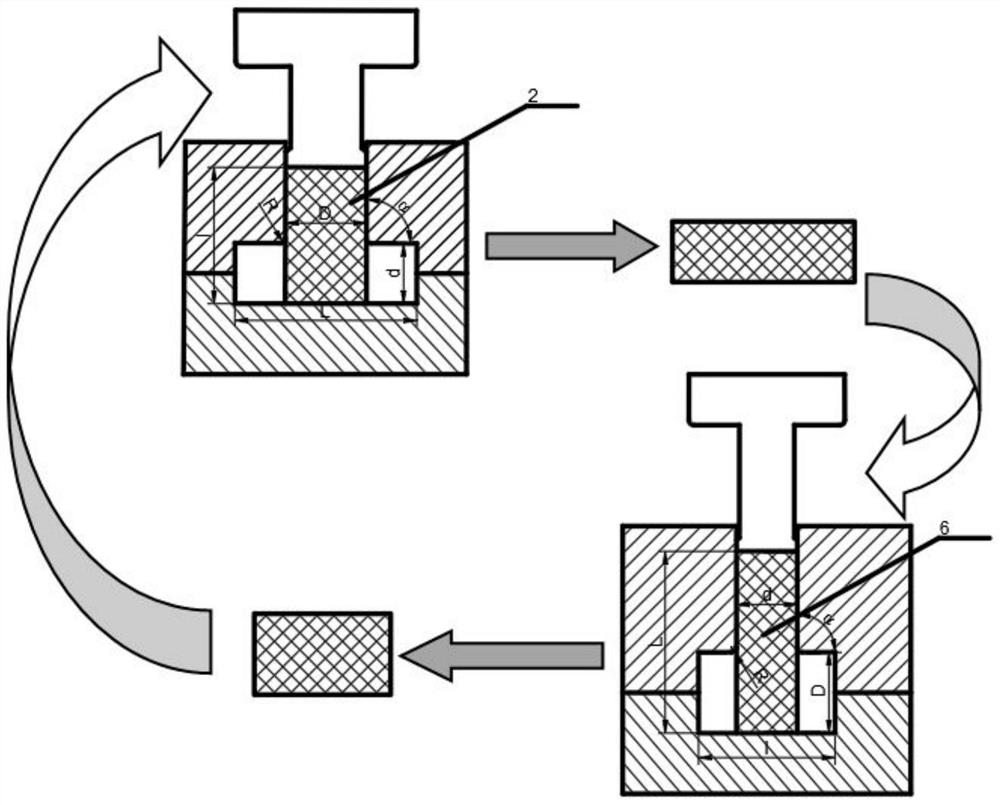

[0053] A method for preparing a high-performance magnesium alloy with large plastic deformation, comprising the steps of:

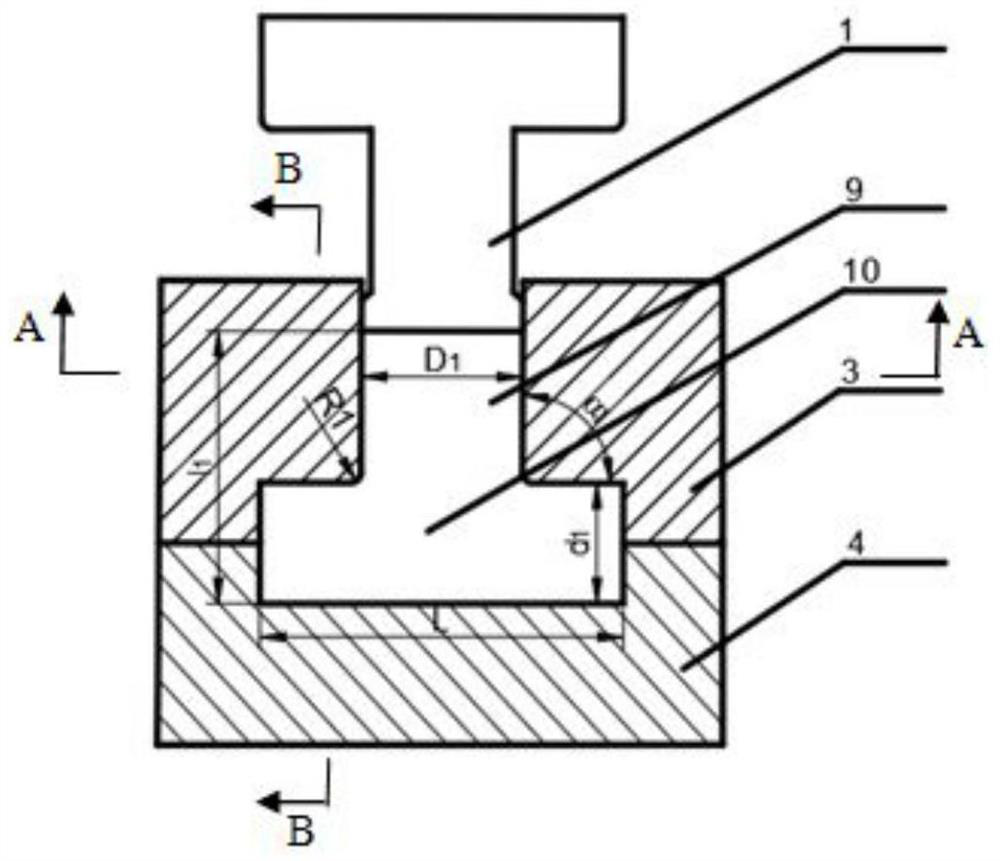

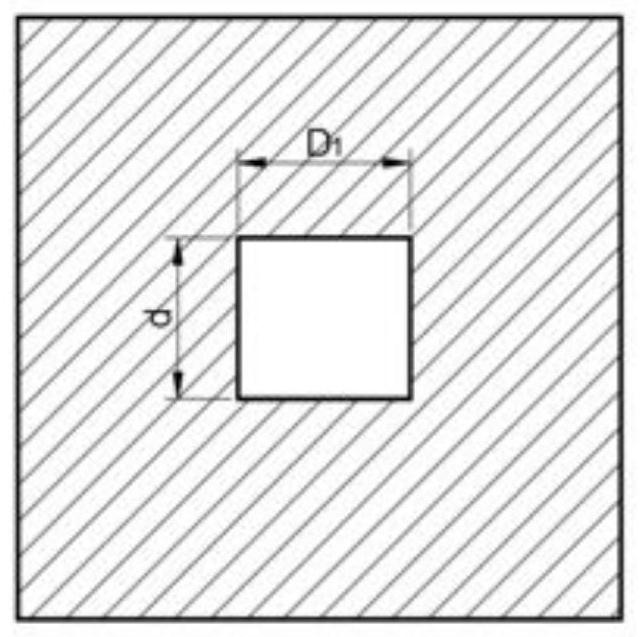

[0054] Step 1. Select a die with a die-extrusion ratio of 2, select the corresponding magnesium alloy billet size according to the die size as 3mm*8.1mm*3mm, and the die-extrusion channel size as 3mm*8mm*3mm, place the magnesium alloy billet Put it into a muffle furnace with a temperature of 400°C for 18 hours, then take it out and put it in pure water to cool to room temperature;

[0055] Step 2. Position and assemble the mold-upper die 3 and the die-down die 4 of the mold one to form a mold-die, and heat the mold-die and mold-punch 1 in a muffle furnace at 400°C for 1.5 hours. And evenly smear lubricant (No. 74 cylinder oil and graphite with a particle size of 400 mesh) in the first cavity of the mold. The mold is fixed on the extruder table;

[0056] Step 3. Preheat the homogenized magnesium alloy billet, heat it in a muffle furnace at 450° C. for 30...

Embodiment 2

[0063] A method for preparing a high-performance magnesium alloy with large plastic deformation, comprising the steps of:

[0064] Step 1. Select a die with a die-extrusion ratio of 1, select the corresponding magnesium alloy billet size according to the die size as 6mm*6.1mm*6mm, and the die-extrusion channel size as 12mm*3mm*6mm, place the magnesium alloy billet Put it into a muffle furnace with a temperature of 450°C for 12 hours, then take it out and put it in pure water to cool to room temperature;

[0065] Step 2. Position and assemble the upper die 3 of die one and the lower die 4 of die one to form a die one die, heat the die one die and die one punch 1 to 320°C for 1 hour, and place them in the die one Apply lubricant evenly in the cavity of the concave mold (70% of No. 74 cylinder oil and 30% of molybdenum disulfide with a particle size of 400 mesh), and then fix the mold and the concave mold on the extruder workbench;

[0066] Step 3. Preheat the homogenized magnes...

Embodiment 3

[0073] A method for preparing a high-performance magnesium alloy with large plastic deformation, comprising the steps of:

[0074] Step 1. Select a die with a die-extrusion ratio of 1.4, select the corresponding magnesium alloy billet size 8mm*13.6mm*7.5mm according to the die size, and the die-extrusion channel size is 18mm*6mm*7.5mm, and the magnesium alloy billet Put it into a muffle furnace with a temperature of 350°C for 25 hours, then take it out and put it into pure water to cool to room temperature;

[0075] Step 2. Position and assemble the mold-upper die 3 and the die-down die 4 of mold one to form mold-die, preheat mold-die and mold-punch 1 in a muffle furnace at 370°C Keep warm for 2 hours, and evenly apply lubricant (glass lubricant with a particle size of 109~190μm) in the first concave mold cavity of the mold, and then fix the first concave mold on the extruder workbench;

[0076] Step 3. Heating the homogenized magnesium alloy billet to 400° C. for 20 minutes,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com