A positive pole piece, its preparation method and electrochemical device

A positive pole piece, electrochemical technology, applied in the field of energy storage, can solve the problems of battery life damage, easy peeling of the coating layer, and decline in the ability of the pole piece to conduct ions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

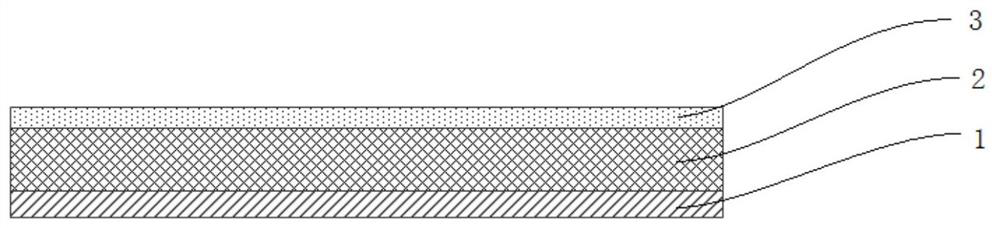

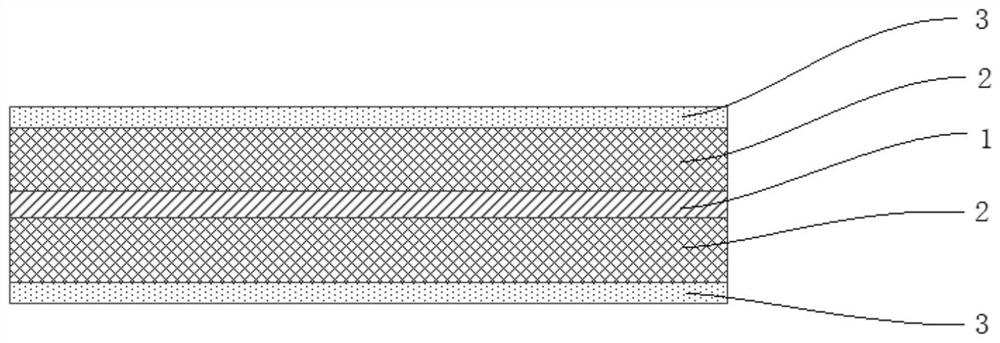

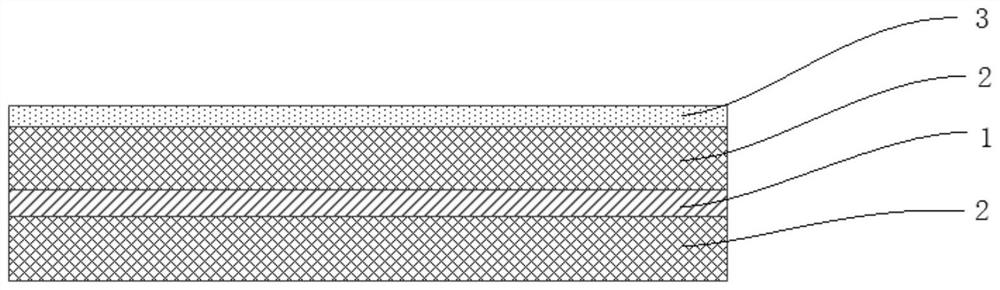

[0048] The method for preparing a positive electrode sheet according to the second aspect of the embodiment of the present application at least includes the following steps:

[0049] Prepare a mixed slurry containing positive electrode active material, binder and conductive agent;

[0050] coating the slurry on at least one surface of the positive electrode collector, and drying to form a positive electrode membrane;

[0051] On the surface of at least one positive electrode diaphragm away from the positive electrode current collector, an inorganic layer with a thickness of 20nm to 2000nm is prepared by vapor deposition; the inorganic layer is a porous dielectric layer without a binder, and the porosity of the inorganic layer is 10% to 60%.

[0052]Further optionally, vapor deposition methods include atomic layer deposition (Atomic Layer Deposition, ALD), chemical vapor deposition (Chemical Vapor Deposition, CVD), physical vapor deposition (Physical VaporDeposition, PVD) and ...

Embodiment

[0079] The lithium ion secondary battery is prepared by the above method, and inorganic layers with different thicknesses and porosities are prepared on the positive electrode diaphragm of the positive electrode sheet by the above gas phase deposition method.

[0080] The specific process parameters are: the target material is metal aluminum, and the vacuum degree of the deposition chamber is less than 1×10 -3 Pa, when the target material is Al metal, the heating evaporation current is 190A, the oxygen flow rate is 300sccm, the plasma power is about 300W to activate the reaction gas, and the process time is 5min.

[0081] The specific parameters of the prepared positive electrode sheet are shown in Table 1.

[0082] Among them, alumina powder is mixed with polyvinylidene fluoride binder (binder content 50%), and coated on the surface of the positive electrode diaphragm. Due to process limitations, the minimum coating thickness can only be 2000nm, that is, the positive electrod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com