Nickel-plated copper material and preparation method and application thereof

A nickel-plated copper and nickel-plated technology, which is applied to electrical components, circuits, battery pack components, etc., can solve the problems that cannot meet the requirements of high-rate lithium-ion battery negative electrode tabs, reduce the corrosion resistance of materials, and have no clear indications, etc. , to achieve the effective recovery of metal ion concentration, enhance the bonding strength, and improve the corrosion resistance of electrolyte

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

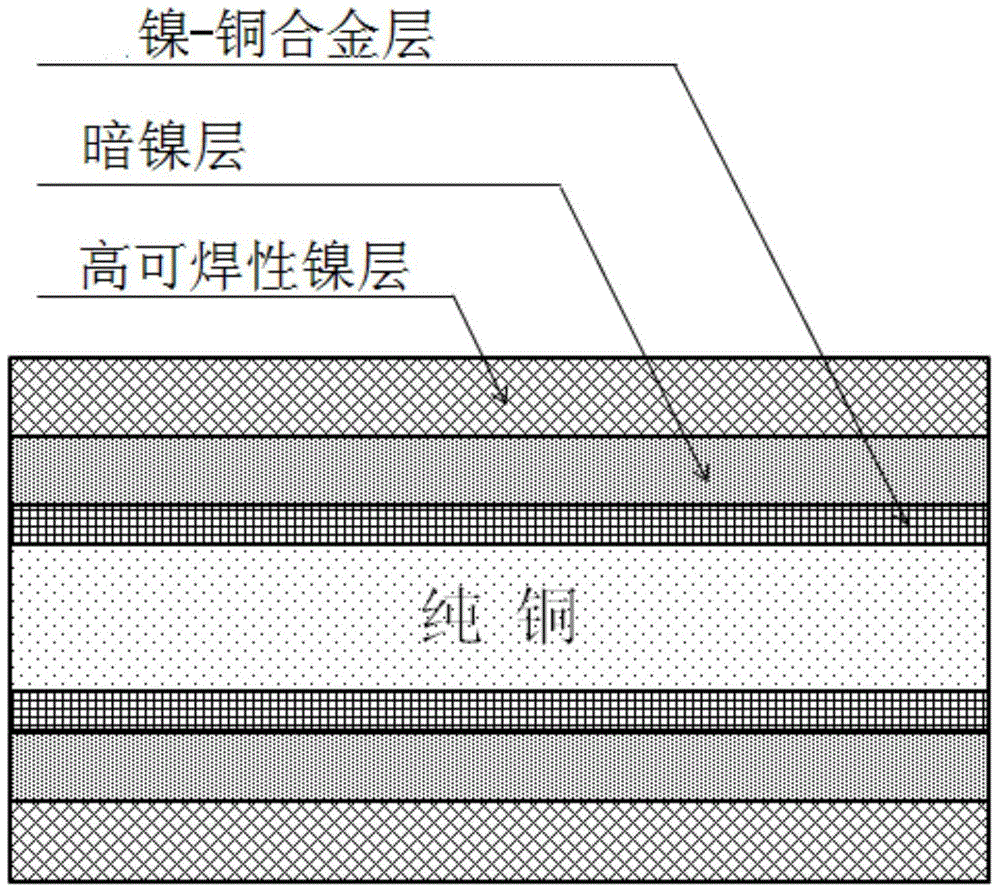

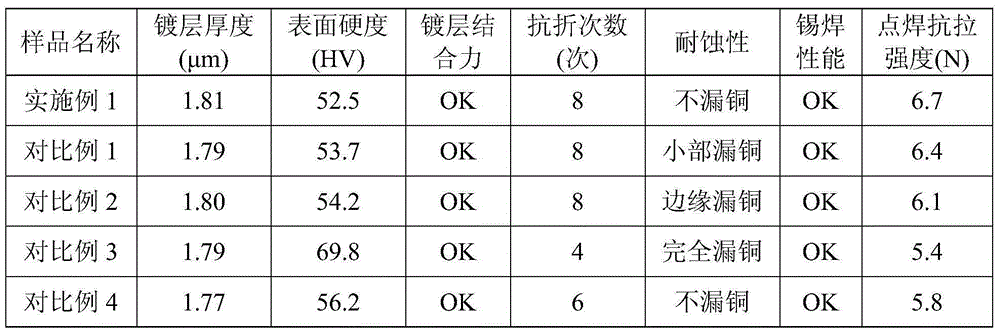

[0069] The preparation method of a nickel-plated copper material of the present invention is used as a high-rate lithium-ion battery tab material, using semi-hard pure copper as the base material, and the electrodeposited thickness is 0.4 μm and the grain size is 50-100 nm on both sides of the base with a small current. Dark nickel coating, and then on the dark nickel coating, electrodeposit a high-solderability nickel coating with a thickness of 1.4 μm and a grain size of 0.4-1.0 μm. Finally, the material is heat treated in a reducing atmosphere at 550 ° C for 2 h and decontaminated at 200 ° C for 4 h. Hydrogen heat treatment process to form a 0.3μm copper-nickel alloy layer.

specific Embodiment approach

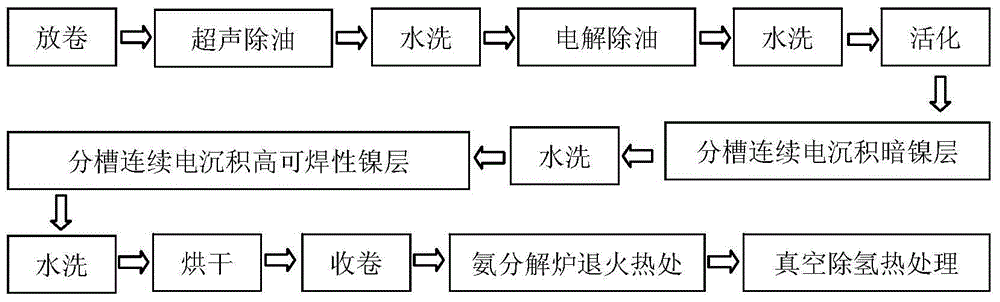

[0070] Its specific implementation method comprises the following steps:

[0071] (1) Pretreatment: Ultrasonic degreasing, electrolytic degreasing and activation treatment are performed on the pure copper strip. The ultrasonic degreasing temperature is 45°C, the ultrasonic frequency is 20kHz, and the degreasing time is 1min. The degreasing liquid formula is sodium carbonate 30g / L, trisodium phosphate 20g / L, and sodium hydroxide 30g / L. Electrolytic degreasing temperature is 55℃, current density is 5A / dm 2 , oil removal time 1.5min, oil removal formula sodium carbonate 30g / L, trisodium phosphate 20g / L, sodium hydroxide 30g / L. The concentration of sulfuric acid in the activation treatment is 8%, the solution temperature is 25°C, and the treatment is about 1 min.

[0072] (2) Electrodeposited nickel coating: including electrodeposited dark nickel layer and electroplated high solderability nickel coating. The formula of the dark nickel solution is nickel sulfate 300g / L, nickel c...

Embodiment 2

[0085] The preparation method of a nickel-plated copper material of the present invention is used for high-rate lithium-ion battery tab materials, using soft pure copper as the base material, and electrodepositing the thickness of 0.2 μm on both sides of the base with a small current electrodeposition thickness of 50-100 nm and a grain size of 50-100 nm. Dark nickel coating, and then electro-deposit a highly solderable nickel coating with a thickness of 1 μm and a grain size of 0.4 to 1.0 μm on the dark nickel layer, and finally the material is heat treated in a reducing atmosphere at 650°C for 2.5h and dehydrogenated at 260°C for 4h Heat treatment process to form a 0.5μm copper-nickel alloy layer.

[0086] Its specific implementation method comprises the following steps:

[0087] (1) Pretreatment: Ultrasonic degreasing, electrolytic degreasing and activation treatment are performed on the pure copper strip. The ultrasonic degreasing temperature is 50°C, the ultrasonic freque...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com