Drill bit for ultra-high rotating speed drilling of deep hard stratum

A technology for hard formations and drill bits, which is applied to drill bits, drilling equipment, and earthwork drilling and production. It can solve problems such as difficulty in maintaining mechanical properties, insufficient rock-breaking ability of drill bits, and shortened service life of drill bits, so as to promote drilling fluid circulation and improve drilling efficiency. Improve efficiency, smooth transition effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

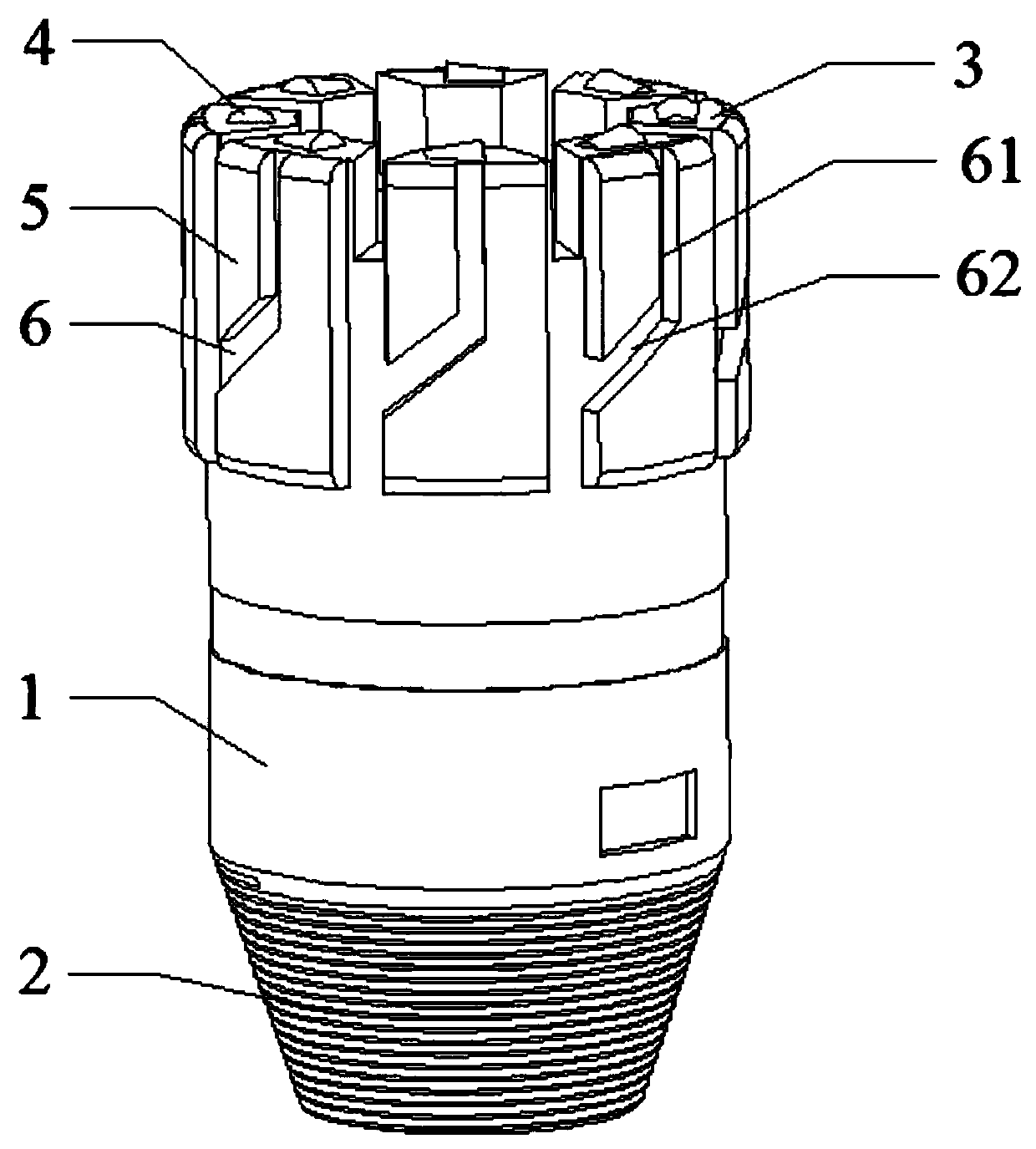

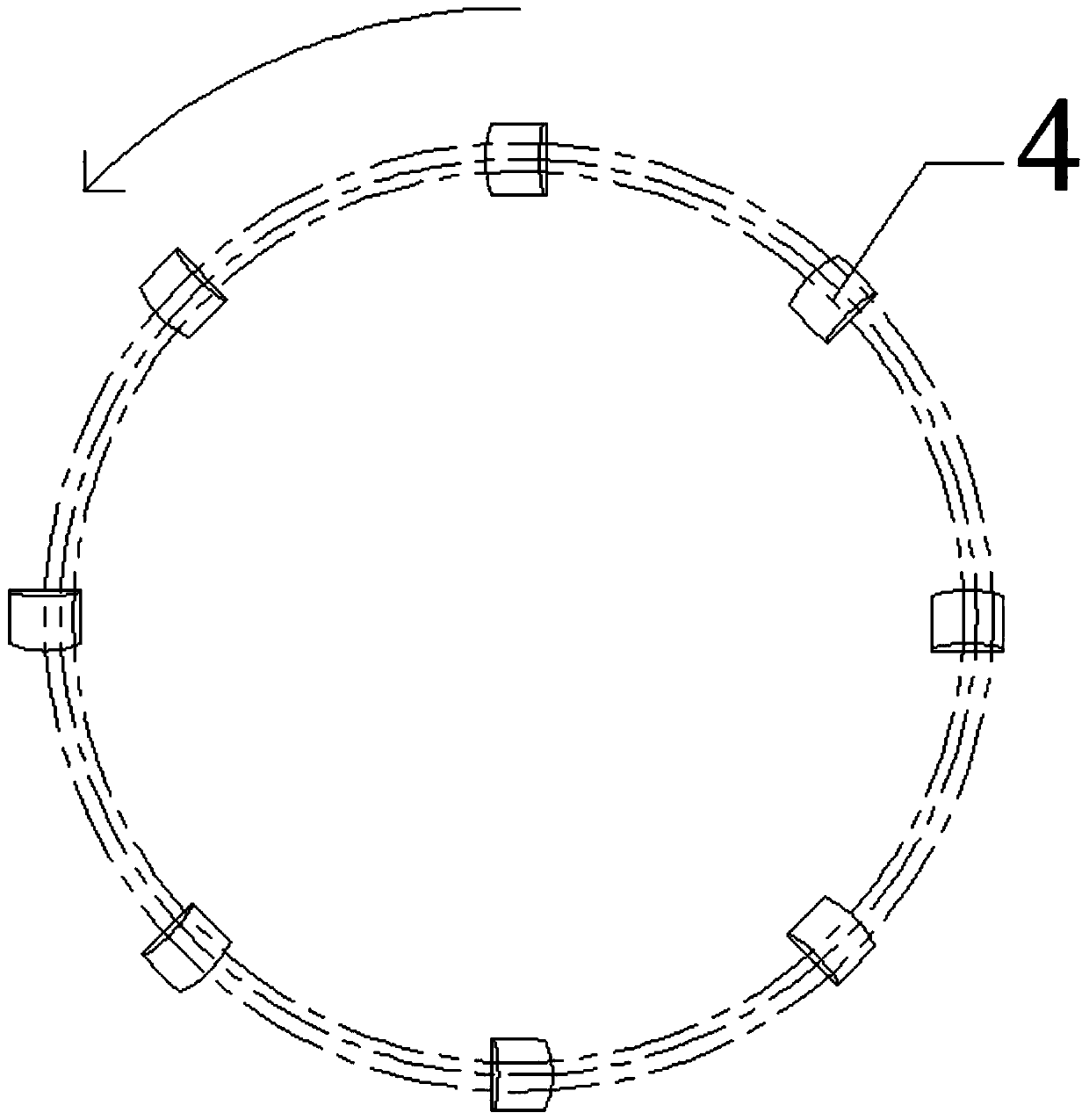

[0036] Such as Figure 1-2 As shown, the drill bit used for ultra-high-speed drilling in deep hard formations in this embodiment includes a drill bit body 1, the bottom end of the drill bit body 1 is fixedly connected with the joint 2, and the top end is fixedly provided with eight bit matrixes that are evenly distributed along the circumference and of equal size. 3. There is an interval between two adjacent drill carcasses 3, and a reinforced polycrystalline diamond cutting tooth 4 is fixed on the working surface of each drill carcass 3; eight reinforced polycrystalline diamond cutting teeth 4 All have the same orientation and are distributed on the circumference of three concentric circles with different radii, refer to figure 2 , the three reinforced polycrystalline diamond cutting teeth 4 on the left are distributed on the circumference of the concentric circle with a larger radius, the two reinforced polycrystalline diamond cutting teeth 4 in the middle are distributed o...

Embodiment 2

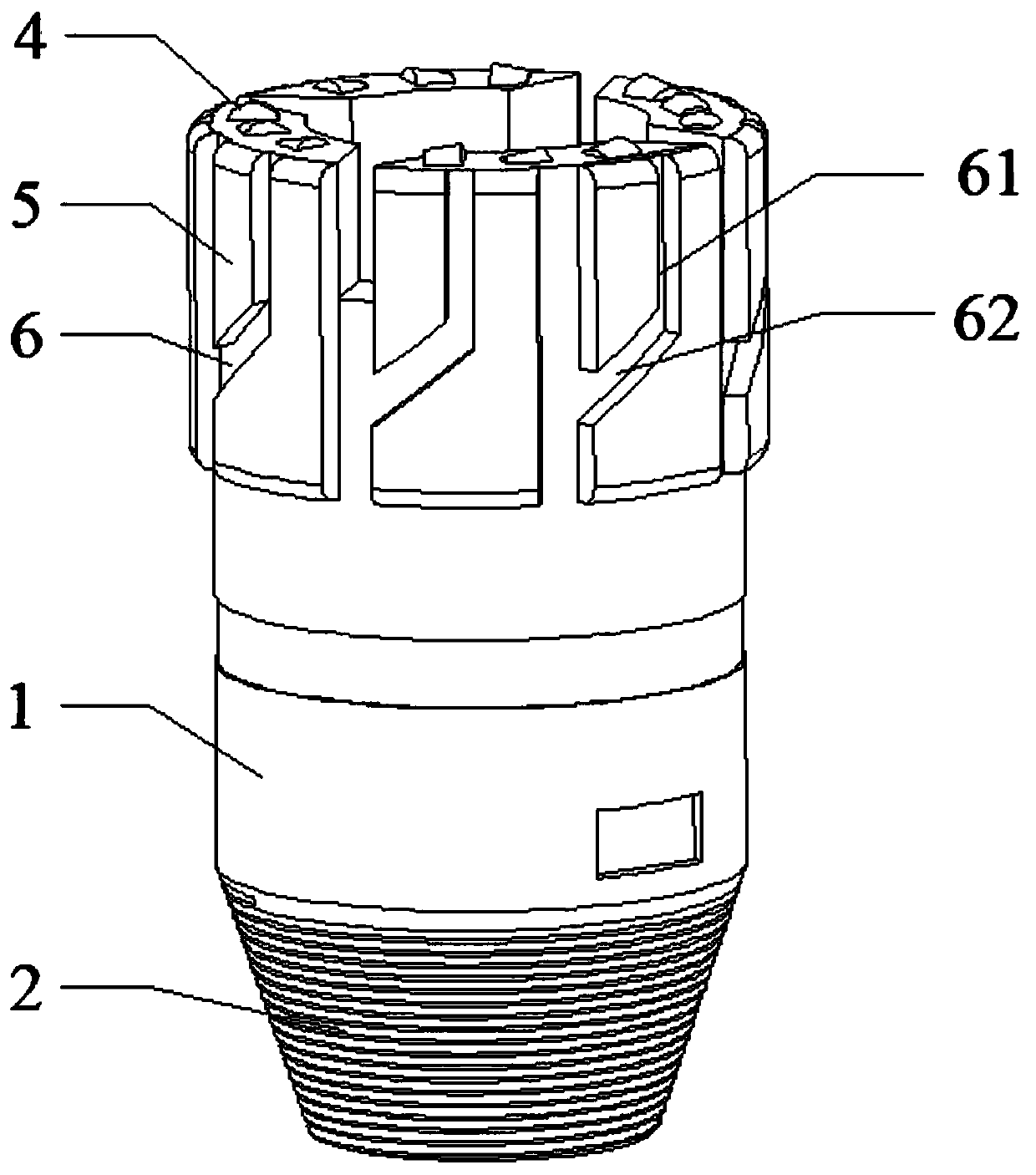

[0042] This embodiment provides a drill bit for ultra-high-speed drilling in deep hard formations. On the basis of Embodiment 1, the drill bit for ultra-high-speed drilling in deep hard formations of this embodiment also has the following characteristics: image 3 As shown, the number of drill carcass 3 in this embodiment is four, and the working surface of each drill carcass 3 is uniformly fixed with three reinforced polycrystalline diamond cutting teeth 4; 12 reinforced polycrystalline diamond cutting teeth 4 have the same orientation and are distributed on the same circumference. Also comprise eight gauge gauges 5 in the present embodiment, difference is that the sidewall of each carcass is connected with two gauge gauges 5 that are arranged at intervals. In this embodiment, by reducing the quantity of the drill matrix 3 and increasing the quantity of the reinforced polycrystalline diamond cutting teeth 4, compared with the first embodiment, on the basis of sacrificing a sm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com