An automatic control processing device for large-scale new energy auto parts with high thermal conductivity radiator

A technology of automatic control and processing device, applied in metal processing, manufacturing tools, metal processing equipment, etc., can solve the problems of unguaranteed installation quality of main chip, high cost of high thermal conductivity radiator, low work efficiency, etc. The effect of breadth, improving production efficiency, and improving machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

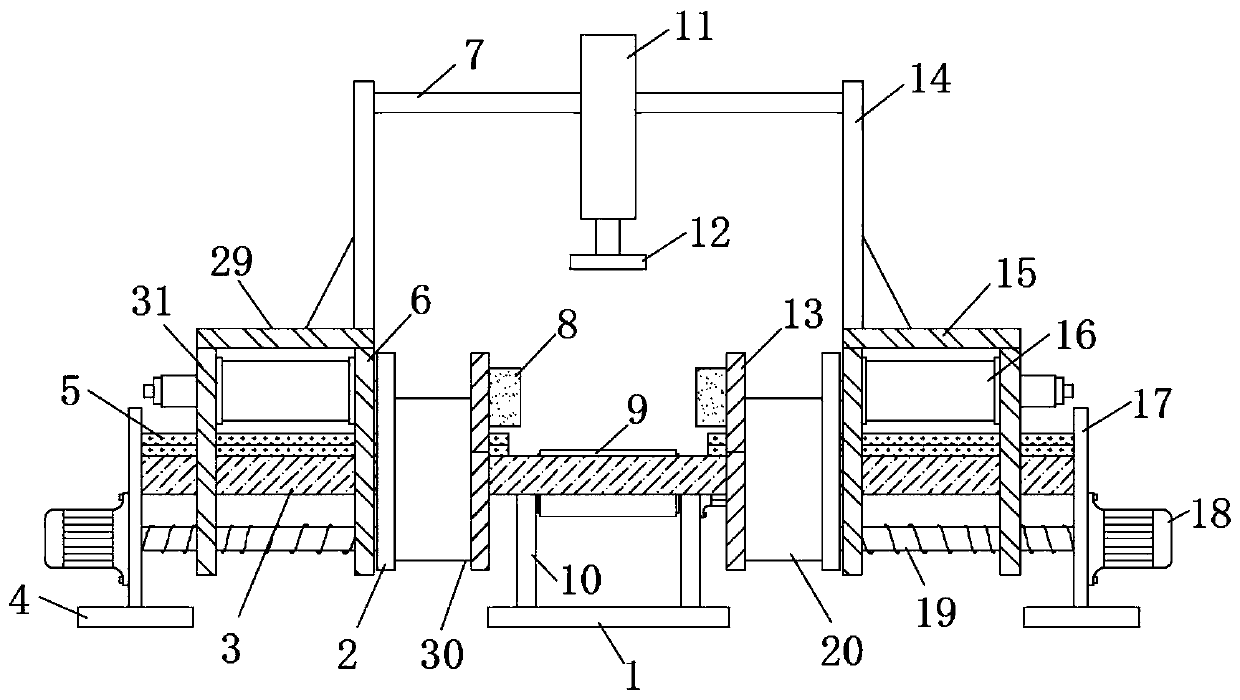

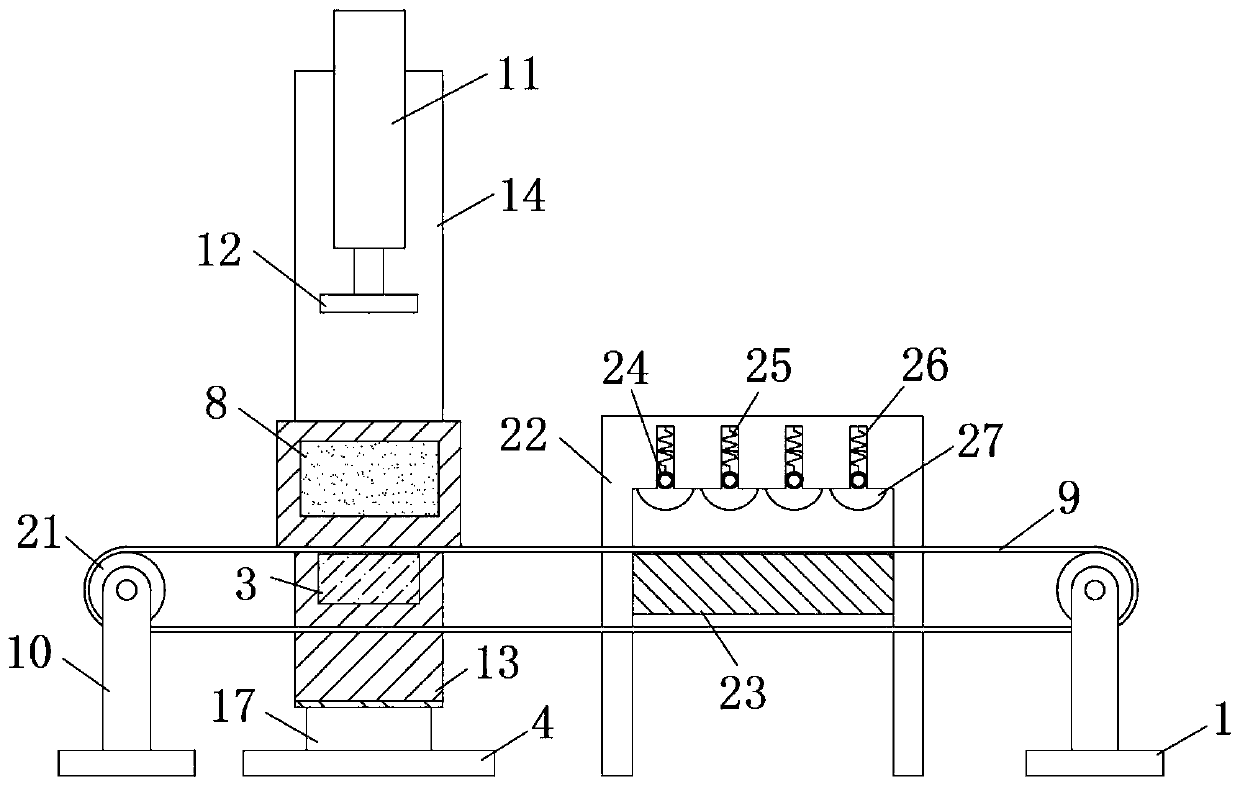

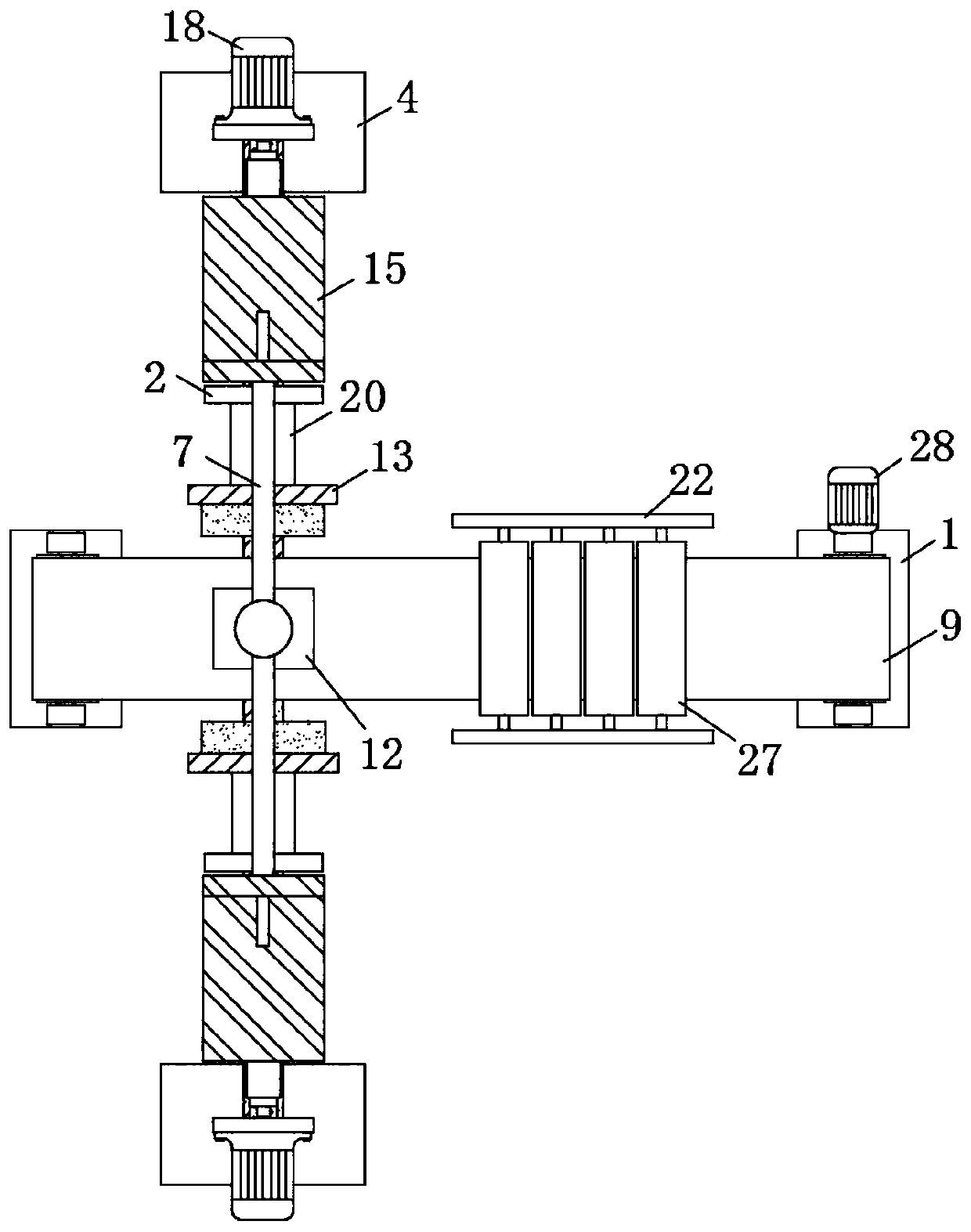

[0031] refer to Figure 1-3 , an automatic control processing device for large-scale new energy auto parts with high thermal conductivity radiators, including two symmetrically arranged first support seats 1, symmetrically arranged two second support seats 4, and symmetrically arranged two mounting frames 22, and The line between the two first support bases 1 and the line between the two second support bases 4 are perpendicular to each other.

[0032] Two first support frames 10 are symmetrically and fixedly connected on each first support base 1, and a first motor 28 is installed on the side wall of one of the first support frames 10, and the two first support frames 10 corresponding to the position Drive rollers 21 are connected to rotate together, and one end of one of the drive rollers 21 passes through the first support frame 10 and is welded to the output shaft of the first motor 28 . The two drive rollers 21 are sheathed with the conveyor belt 9 .

[0033] Each second ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com