Visual fluorescent sensor for ultraviolet detection and method of making same

A fluorescent sensor and ultraviolet technology, applied in photometry, instruments, measuring devices, etc., can solve the problems of low detection sensitivity and expensive detectors, and achieve the effects of simple operation, low cost, and simple manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

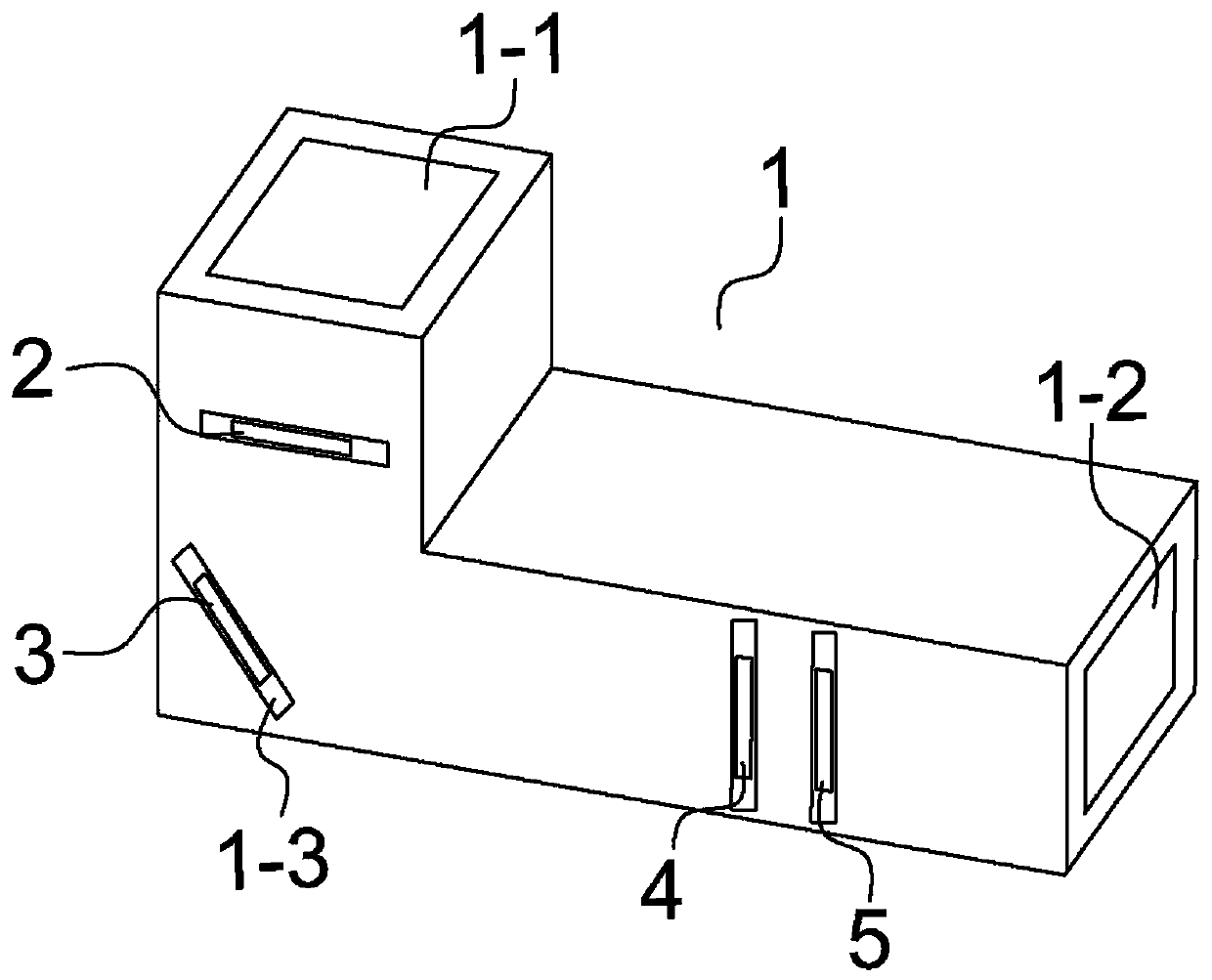

[0037] Example: such as Figure 1~Figure 2 As shown, the visible fluorescent sensor for ultraviolet detection is composed of an imaging channel 1 and functional elements arranged on the imaging channel 1 .

[0038] The imaging channel 1 is in an "L" shape, and its two ends are respectively provided with an ultraviolet light collection window 1-1 and an imaging observation window 1-2, and the surface where the ultraviolet light collection window 1-1 and the imaging observation window 1-2 are located is a plane , and the two planes are perpendicular to each other;

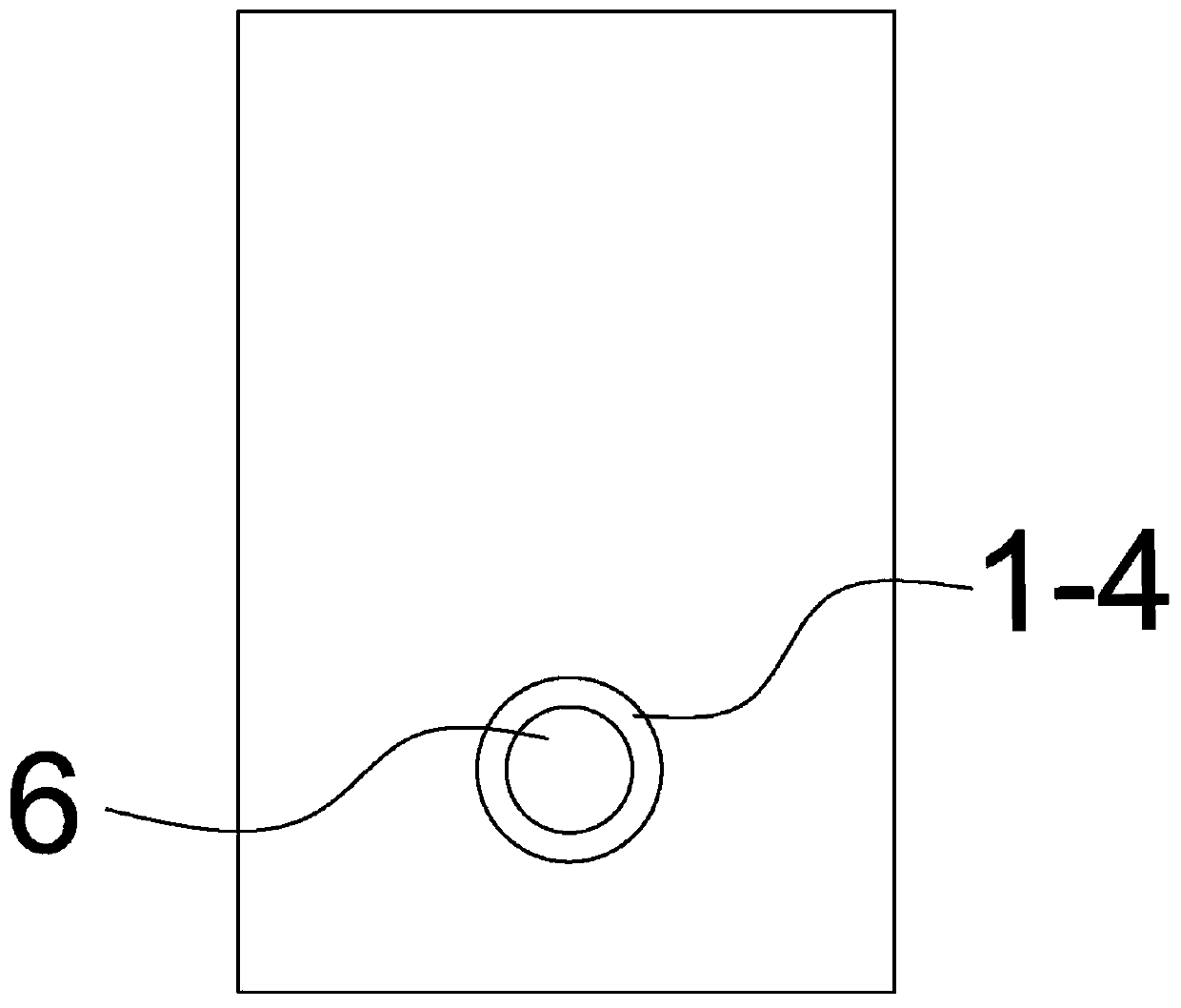

[0039] Functional elements include filter element 2, reflective element 3, fluorescent excitation element 4, imaging element 5, and superimposed light source element 6. In this embodiment, they are ultraviolet filter, gold-plated glass sheet, fluorescent film, hollow circle Shaped aluminum sheet and green LED lamp, the surface where the gold-plated glass sheet is located is a plane, and the plane is set at an angle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com