A preparation method for a composite coating for protection of Cr-containing stainless steel in molten fluoride salt

A composite coating, stainless steel technology, applied in coatings, electrolytic coatings, etc., can solve the problems of poor bonding force, can not completely block the mutual diffusion of elements, etc., and achieves the reduction of electroplating time, the uniform and dense deposition layer, and the reduction of coating porosity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

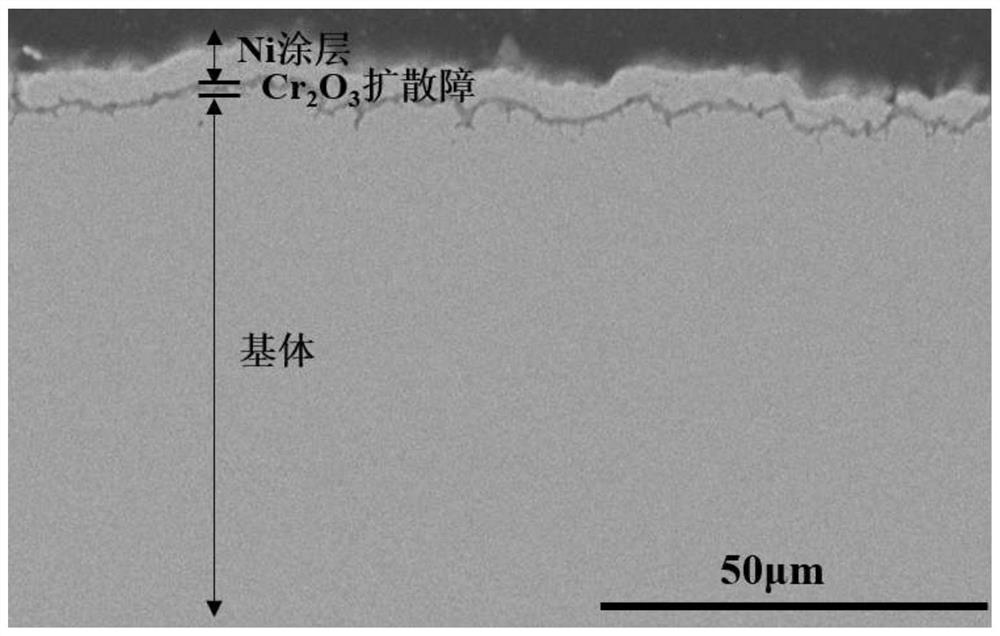

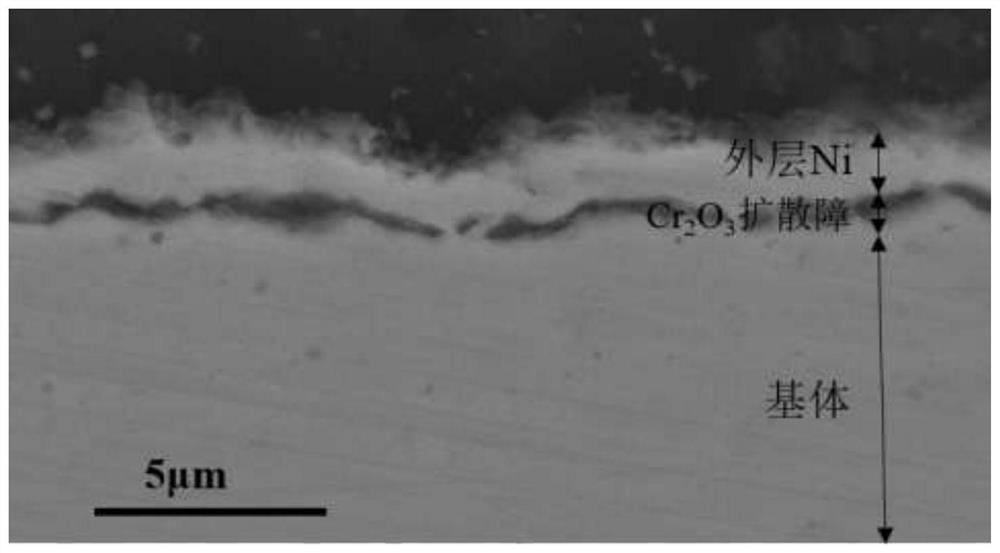

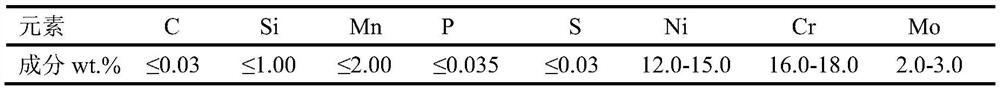

Embodiment 1

[0045] With stainless steel containing about 16wt.% Cr (see Table 1 for composition) as the cathode base material, the stainless steel cathode base material was cut into 15×10×2 mm thin slices, and the nickel sheet was used as the anode base material. The size of the nickel sheet was the same as that of the stainless steel The size of the cathode substrate is equivalent, and the cathode and anode substrates are pretreated, that is, after grinding and chamfering, ultrasonic degreasing with acetone, cleaning with deionized water, acidification, and finally rinsing. Then put it into the plating solution containing NiO nanoparticles (50nm) that has been dispersed (this plating solution contains the following components in every 1L: nickel sulfate hydrate 250g, nickel chloride hydrate 40g, boric acid 40g, lauryl sulfuric acid Sodium 0.3g, nickel oxide powder 20g, and the rest are deionized water) for electroplating. The power supply is an adjustable double pulse power supply, the p...

Embodiment 2

[0051] With stainless steel containing about 16wt.% Cr (see Table 1 for composition) as the cathode substrate, the stainless steel cathode substrate is cut into 15×10×2mm thin slices, and the nickel sheet is used as the anode substrate, and the size of the nickel sheet is the same as that of the stainless steel The size of the cathode substrate is equivalent, and the cathode and anode substrates are pretreated, that is, after grinding and chamfering, acetone ultrasonic degreasing, deionized water cleaning, acidification, and finally rinsing. Then put it into the plating solution containing NiO nanoparticles (50nm) that has been dispersed (this plating solution contains the following components in every 1L: nickel sulfate hydrate 250g, nickel chloride hydrate 40g, boric acid 40g, lauryl sulfuric acid Sodium 0.3g, nickel oxide powder 100g, and the rest are deionized water) for electroplating. The power supply is an adjustable double pulse power supply, the pulse frequency used i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com