A kind of 800mpa grade high yield strength ratio cold-rolled dual-phase steel and its preparation method

A high yield ratio, dual-phase steel technology, applied in the field of cold-rolled dual-phase steel, can solve the problems that dual-phase steel cannot be provided, achieve low cost, improve comprehensive mechanical properties, and reduce the effect of uneven microstructure of finished products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

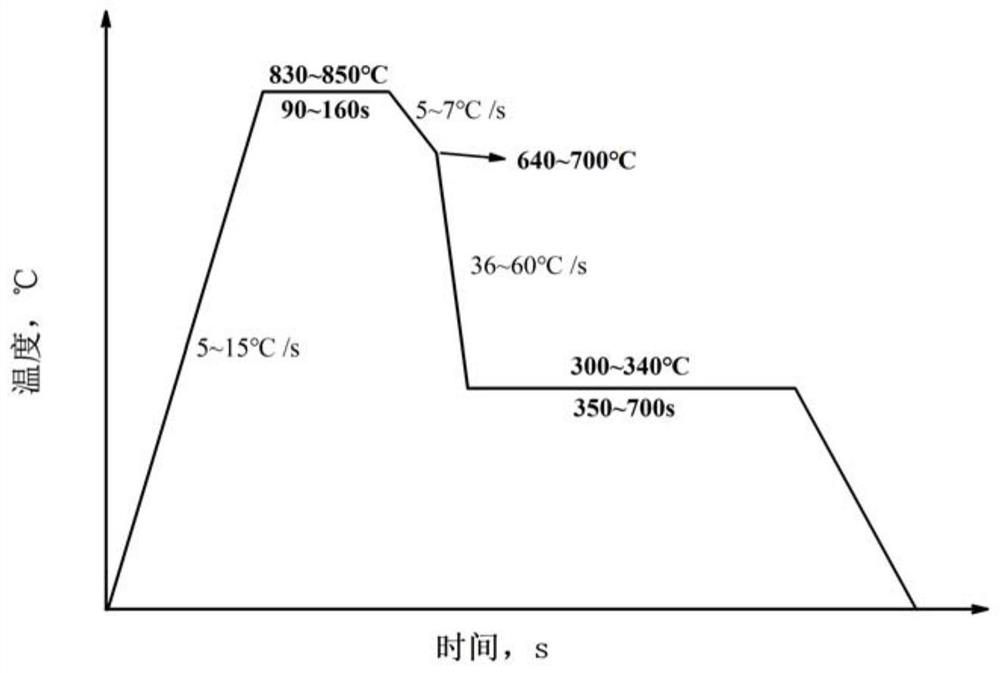

[0057] A kind of preparation method of 800MPa level high yield ratio cold-rolled dual-phase steel of the present invention comprises the following steps:

[0058] S1. Steel smelting and solidification to obtain cast slabs or ingots: steel smelting and solidification are suitable for converter, electric furnace and induction furnace smelting, using continuous casting to produce slabs or die casting to produce ingots, during the continuous casting or die casting process Electromagnetic stirring is used.

[0059] S2. Continuous hot rolling of slab or ingot: heat the slab or ingot to a temperature range of 1180-1260°C, roll the slab or ingot for 5-10 passes by a rough rolling mill, and cast the slab or ingot after rough rolling The thickness of the billet or ingot is 30-50mm, and then rolled by the hot continuous rolling mill for 5-7 passes. After rolling to the required thickness, it is coiled into a steel coil within the temperature range of T1, and the temperature range of T1 i...

Embodiment 1

[0065] An 800MPa grade high yield ratio cold-rolled dual-phase steel in this embodiment has main chemical components and weight percentages as shown in Example 1 in Table 1, wherein P≤0.02%, S≤0.01%.

[0066] The preparation method of a kind of 800MPa grade high yield strength ratio cold-rolled dual-phase steel of this embodiment comprises the following steps:

[0067] S1. Steel smelting and solidification to obtain cast slabs or ingots: steel smelting and solidification are suitable for converter, electric furnace and induction furnace smelting, using continuous casting to produce slabs or die casting to produce ingots, during the continuous casting or die casting process Electromagnetic stirring is used.

[0068] S2. Continuous hot rolling of slab or ingot: heating the slab or ingot to a temperature range of 1180°C, rolling the slab or ingot for 5 passes by the rough rolling mill, and casting the slab or ingot after rough rolling The thickness is 30mm, and then rolled by th...

Embodiment 2

[0072] An 800MPa grade high yield ratio cold-rolled dual-phase steel in this embodiment has main chemical components and weight percentages as shown in Example 2 in Table 1, wherein P≤0.02%, S≤0.01%. The process parameter of the duplex steel preparation method of the present embodiment is with reference to embodiment 1, as follows:

[0073] The preparation method of a kind of 800MPa grade high yield strength ratio cold-rolled dual-phase steel of this embodiment comprises the following steps:

[0074] S1. Steel smelting and solidification to obtain cast slabs or ingots: steel smelting and solidification are suitable for converter, electric furnace and induction furnace smelting, using continuous casting to produce slabs or die casting to produce ingots, during the continuous casting or die casting process Electromagnetic stirring is used.

[0075] S2. Continuous hot rolling of slab or ingot: heating the slab or ingot to a temperature range of 1180°C, rolling the slab or ingot ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com