Fluorescent material and preparation method thereof, optoelectronic device and method for manufacturing optoelectronic device

A technology of optoelectronic devices and fluorescent materials, which is applied in the manufacturing process of optoelectronic devices and the field of optoelectronic devices, to achieve the effects of low manufacturing cost, convenient large-scale application, and favorable promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

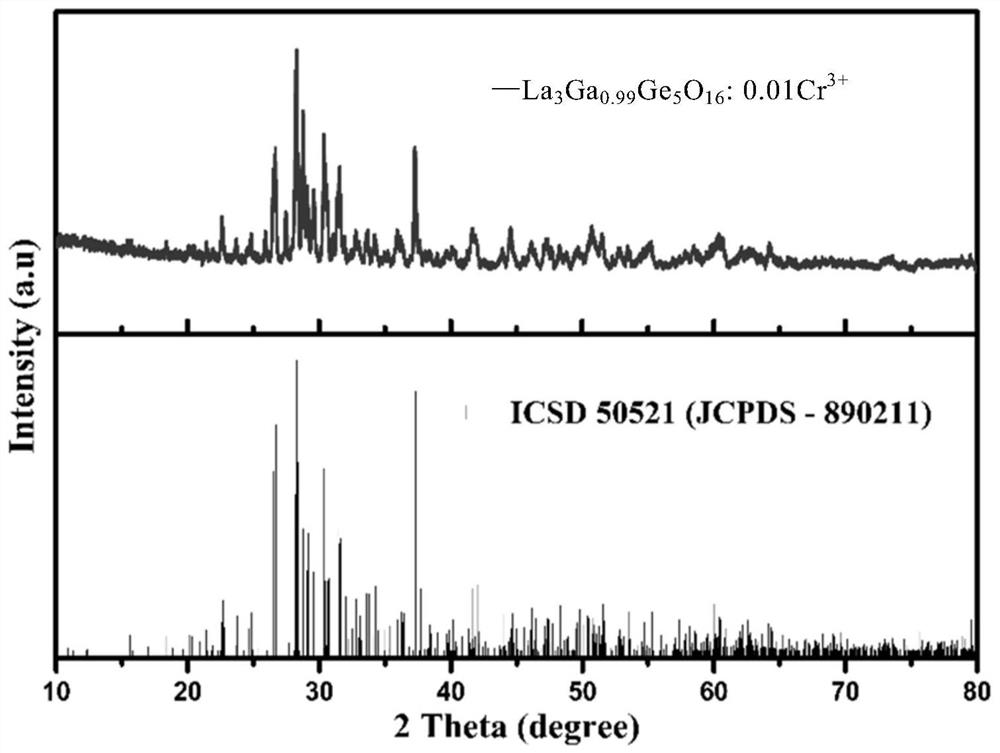

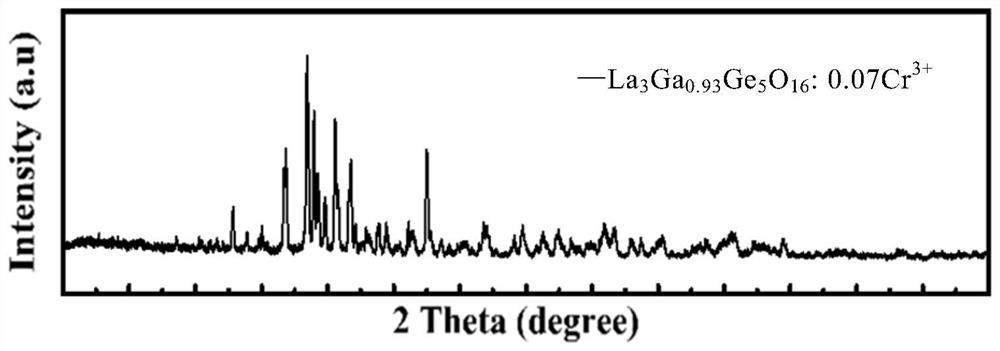

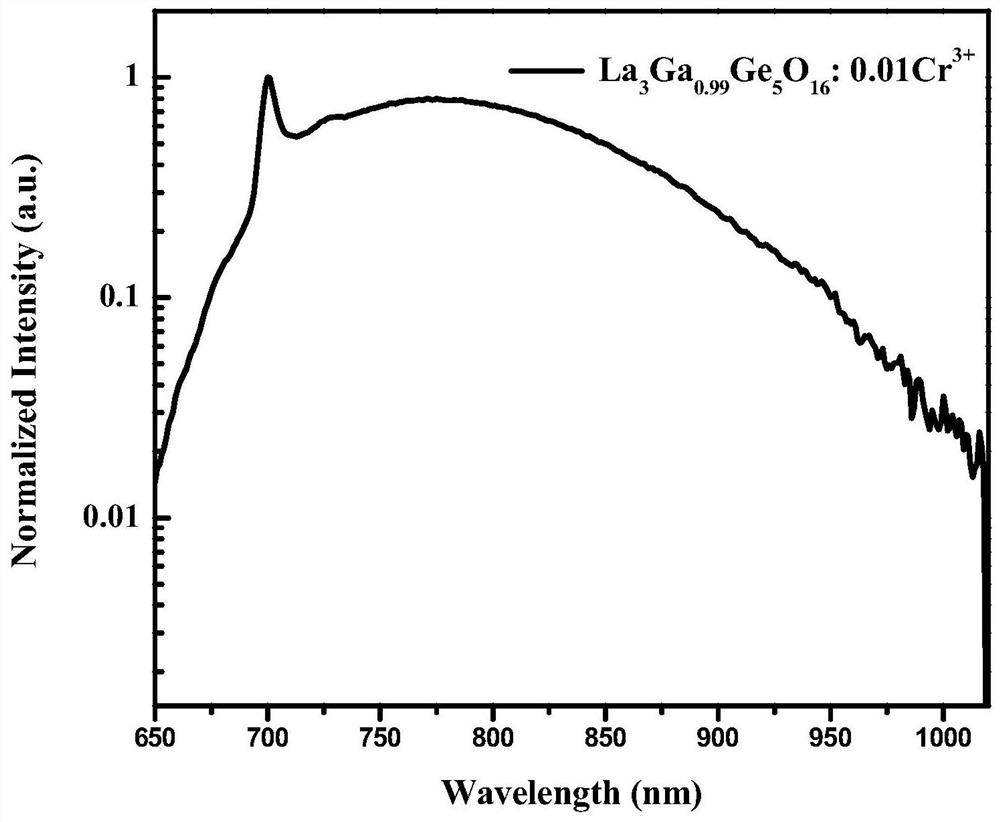

[0091] This embodiment provides a group of fluorescent materials whose general formula is La 3 Ga 1-y Ge 5 o 16 :yCr 3+ , where 0<y≤0.2, the chemical formula of this group of fluorescent materials is as follows:

[0092] La 3 Ga 0.995 Ge 5 o 16 :0.005Cr 3+

[0093] La 3 Ga 0.99 Ge 5 o 16 :0.01Cr 3+

[0094] La 3 Ga 0.97 Ge 5 o 16 :0.03Cr 3+

[0095] La 3 Ga 0.95 Ge 5 o 16 :0.05Cr 3+

[0096] La 3 Ga 0.93 Ge 5 o 16 :0.07Cr 3+

[0097] La 3 Ga 0.91 Ge 5 o 16 :0.09Cr 3+

[0098] La 3 Ga 0.89 Ge 5 o 16 :0.11Cr 3+

[0099] La 3 Ga 0.87 Ge 5 o 16 :0.13Cr 3+

[0100] The preparation method of this group of fluorescent materials is: according to the stoichiometric ratio in the molecular formula of the fluorescent materials, accurately weigh the raw material La 2 o 3 , Ga 2 o 3 、GeO 2 and Cr 2 o 3 ;Put the weighed raw materials into an agate mortar and grind to mix evenly, then transfer the resulting mixture to an alumina crucibl...

Embodiment 2

[0105] This embodiment provides a fluorescent material with a molecular formula of La 2.97 Ga 0.99 Ge 5 o 16 :0.03Gd 3+ ,0.01Cr 3+ , the preparation method of the fluorescent material is as follows:

[0106] Accurately weigh the raw material La according to the stoichiometric ratio in the molecular formula of the fluorescent material 2 o 3 , Ga 2 o 3 、GeO 2 、Gd 2 o 3 and Cr 2 o 3 , put the weighed raw material into an agate mortar and grind it to mix evenly, then transfer the mixture to an alumina crucible, and place it in a tube furnace for sintering in an air atmosphere, controlling the sintering temperature to 1300°C The sintering time is about 6 hours, and after being cooled in the furnace, it is ground into powder to obtain fluorescent materials.

[0107] Such as Figure 5 As shown, the XRD diffraction pattern of the fluorescent material is compared with the standard X-ray diffraction pattern, and all the diffraction peaks of the fluorescent material are co...

Embodiment 3

[0111] This embodiment provides a fluorescent material whose molecular formula is La 2.97 Ga 0.99 Ge 5 o 16 :0.03Yb 3+ ,0.01Cr 3+ , the preparation method of the fluorescent material is as follows:

[0112] Accurately weigh the raw material La according to the stoichiometric ratio in the molecular formula of the fluorescent material 2 o 3 , Ga 2 o 3 、GeO 2 , Yb 2 o 3 and Cr 2 o 3 , put the weighed raw material into an agate mortar and grind it to mix evenly, then transfer the mixture to an alumina crucible, and place it in a tube furnace for sintering in an air atmosphere, controlling the sintering temperature to 1300°C The sintering time is about 6 hours, and after being cooled in the furnace, it is ground into powder to obtain fluorescent materials.

[0113] Such as Figure 7 As shown, the XRD diffraction pattern of the fluorescent material is compared with the standard X-ray diffraction pattern, and all the diffraction peaks of the fluorescent material are co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radiant flux | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com